Preparation and application of super-long-cycle polyatom-doped hollow carbon electrode material

A polyatomic, carbon electrode technology, applied in the preparation/purification of carbon, battery electrodes, circuits, etc., can solve the problems affecting the performance of potassium ion batteries, unfavorable potassium ion adsorption, small specific surface area, etc., and achieve abundant defects and active sites. point, improve the rate performance and cycle stability, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

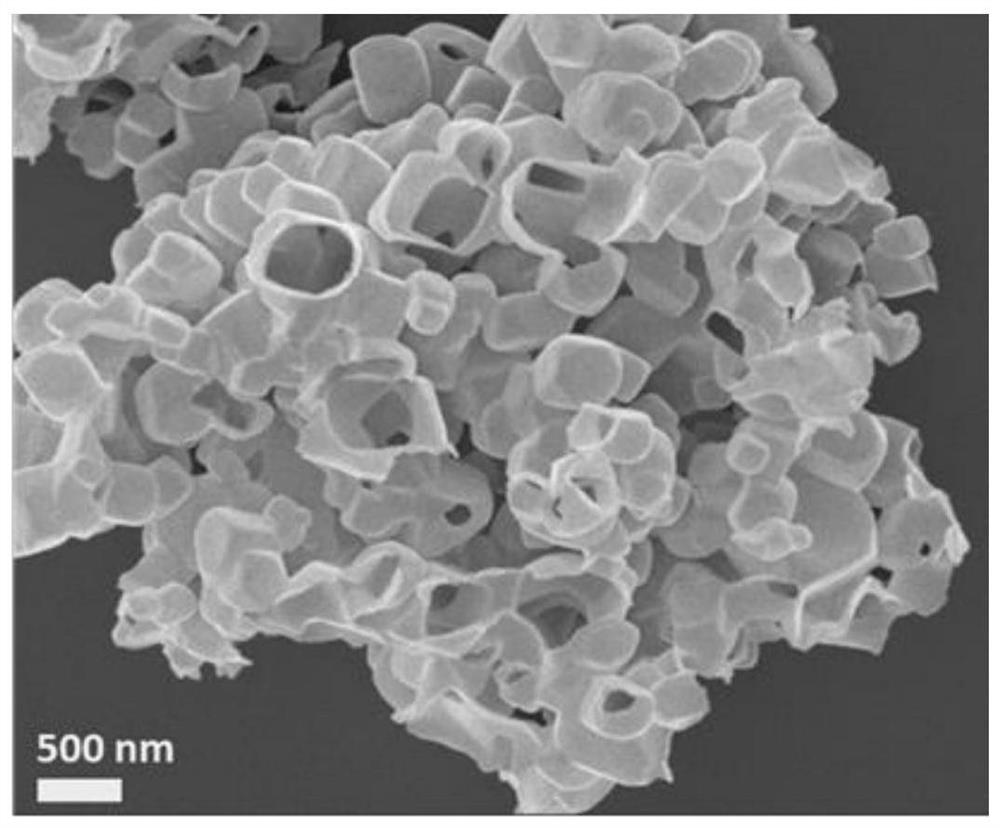

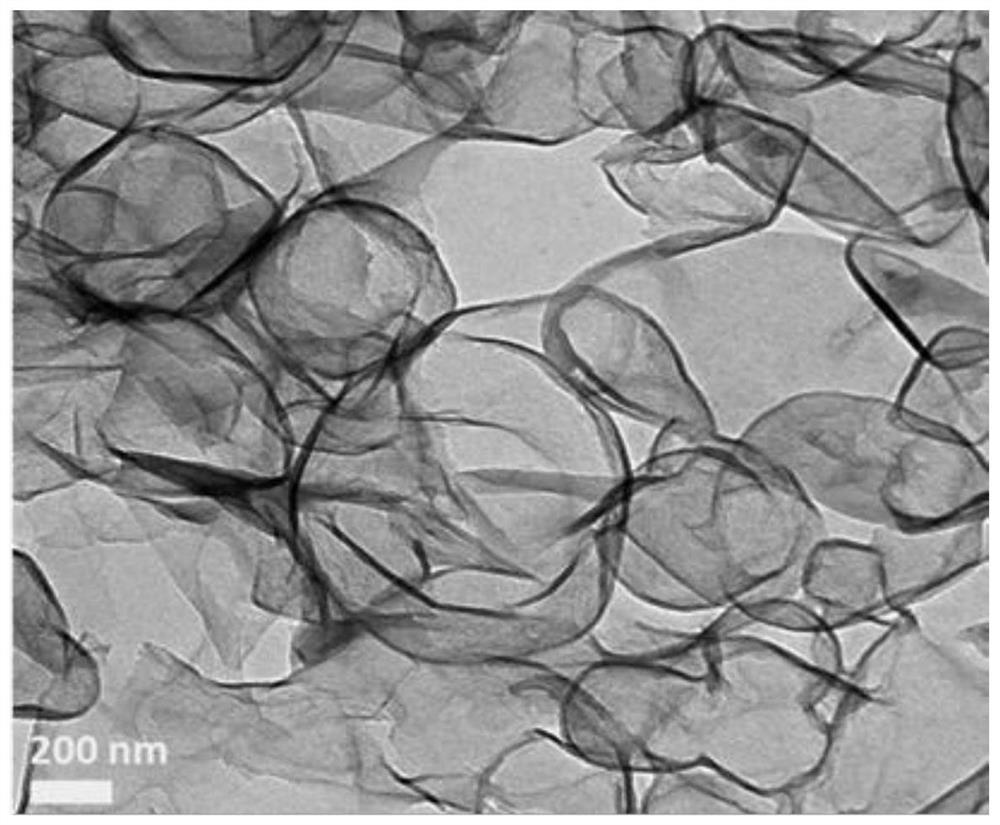

[0034] Step 1: Disperse 400 mg of nano magnesium oxide with a particle size of 50 nm in 50 ml of methanol.

[0035] Step 2: Dissolve hexachlorotriphosphazene and 4,4'-dihydroxydiphenylsulfone with a total mass of 228mg and a molar ratio of 1:2.25 in 10ml of methanol.

[0036] Step 3: Add the solution in Step 2 to the solution in Step 1, add 185 μL of triethylamine during stirring, and keep polymerization at room temperature for 6 hours.

[0037] Step 4: The product obtained in Step 3 was centrifuged, washed and dried, and then placed in a tube furnace for heat treatment. In a nitrogen atmosphere, the temperature was raised from room temperature to 900 °C at a heating rate of 2 °C / min, and kept for 2 hours to fully Calcination, after the calcination is completed, a calcined product is obtained.

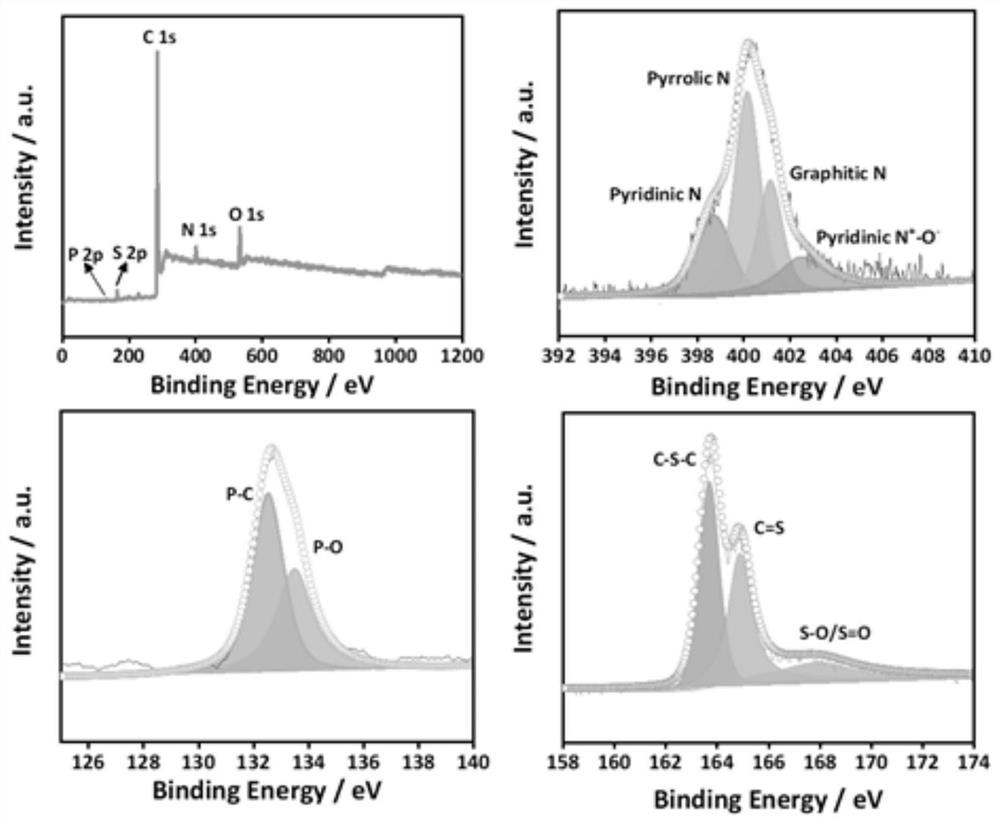

[0038] Step 5: Remove the magnesium oxide template from the calcined product obtained in Step 4 with 3 mol / L hydrochloric acid to obtain nitrogen, phosphorus, and sulfur-doped hollow ...

Embodiment 2

[0040] Step 1: Disperse 400 mg of nano magnesium oxide with a particle size of 100 nm in 50 ml of methanol.

[0041] Step two to step five are consistent with embodiment 1.

Embodiment 3

[0043] Steps 1 to 3 are consistent with Example 1.

[0044] Step 4: The product obtained in Step 3 was centrifuged, washed and dried, then placed in a tube furnace for heat treatment, and heated from room temperature to 700°C in a nitrogen atmosphere at a heating rate of 2°C / min, and kept for 2 hours for full Calcination, after the calcination is completed, a calcined product is obtained.

[0045] Step 5 is consistent with Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com