A 3D printing drug-loaded bone defect filler scaffold and its preparation method and application

A 3D printing and filler technology, used in 3D printing, drug delivery, bone implants, etc., can solve the problems of non-absorbable metabolism of stabilizers and auxiliaries, the proportion of active ingredients is reduced, and there is no sustained release effect. The effect of inhibiting bacterial or tumor cell growth, promoting osteogenesis in vivo, and facilitating regulation of release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A preparation method of a 3D printed drug-loaded bone defect filler scaffold is as follows:

[0068] (1) After drying the tricalcium phosphate (β-TCP) powder and the hydroxyapatite (HA) powder, under vacuum at 60°C overnight, use a 500-mesh stainless steel screen to sieve the two powders respectively. The two powders are reserved;

[0069] (2) Fully dissolve 0.8g of L-polylactic acid (PLLA) in 3.5mL of dichloromethane, then slowly add 1.2g of sieved tricalcium phosphate (β-TCP) and 2g of hydroxyapatite (HA) powder, Then 1 mL of absolute ethanol was added, and the matrix slurry was obtained by fully stirring at 1500 rpm for 0.5 h;

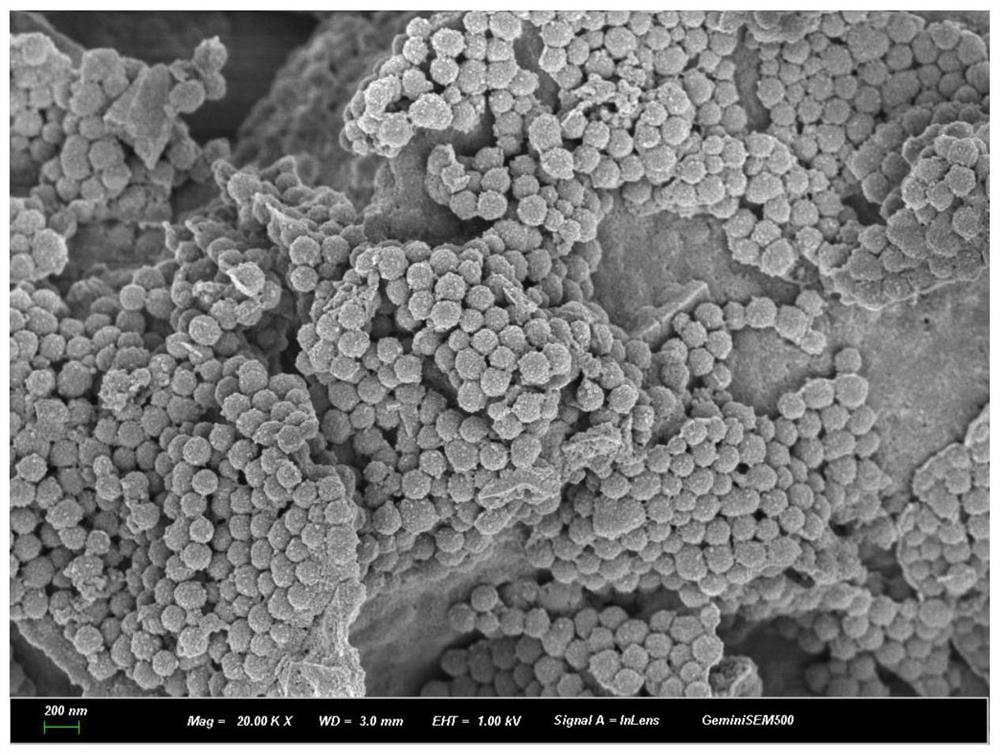

[0070] (3) Dissolve 450 mg of dopamine in 6 mL of ultrapure water, fully dissolve to obtain solution A, fully mix 81 mL of ethanol, 36 mL of ultrapure water and 2.7 mL of ammonia to obtain solution B, add A to solution B to react for 24 hours, and then After centrifugation to remove the supernatant, freeze-dried to obtain polydopamine (PDA)...

Embodiment 2

[0080] A preparation method of a 3D printed drug-loaded bone defect filler scaffold is as follows:

[0081] (1) After drying the tricalcium phosphate (β-TCP) powder and the hydroxyapatite (HA) powder, under vacuum at 60°C overnight, use a 500-mesh stainless steel screen to sieve the two powders respectively. The two powders are reserved;

[0082] (2) Fully dissolve 1.44g L-polylactic acid (PLLA) in 5.4mL dichloromethane, then slowly add sieved 2.88g tricalcium phosphate (β-TCP) and 2.88g hydroxyapatite (HA) powder , and then add 1.8 mL of anhydrous ethanol, and fully stir at 1500 rpm for 1 h to obtain a matrix slurry;

[0083] (3) Dissolve 450 mg of dopamine in 6 mL of ultrapure water, fully dissolve to obtain solution A, fully mix 81 mL of ethanol, 36 mL of ultrapure water and 2.7 mL of ammonia to obtain solution B, add A to solution B to react for 24 hours, and then The supernatant was removed by centrifugation and then freeze-dried to obtain 200 nm polydopamine (PDA) micr...

Embodiment 3

[0092] A preparation method of a 3D printed drug-loaded bone defect filler scaffold is as follows:

[0093] (1) After drying the tricalcium phosphate (β-TCP) powder and the hydroxyapatite (HA) powder, under vacuum at 60°C overnight, use a 500-mesh stainless steel screen to sieve the two powders respectively. The two powders are reserved;

[0094] (2) Fully dissolve 1 g of L-polylactic acid (PLLA) in 4 mL of dichloromethane, then slowly add sieved 1.5 g of tricalcium phosphate (β-TCP) and 2.5 g of hydroxyapatite (HA) powder, and then Add 1 mL of absolute ethanol, and fully stir at 1200 rpm for 1 h to obtain a matrix slurry;

[0095] (3) Dissolve 450 mg of dopamine in 6 mL of ultrapure water, fully dissolve to obtain solution A, fully mix 81 mL of ethanol, 36 mL of ultrapure water and 2.7 mL of ammonia to obtain solution B, add A to solution B to react for 24 hours, and then The supernatant was removed by centrifugation and then freeze-dried to obtain 200 nm polydopamine (PDA)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com