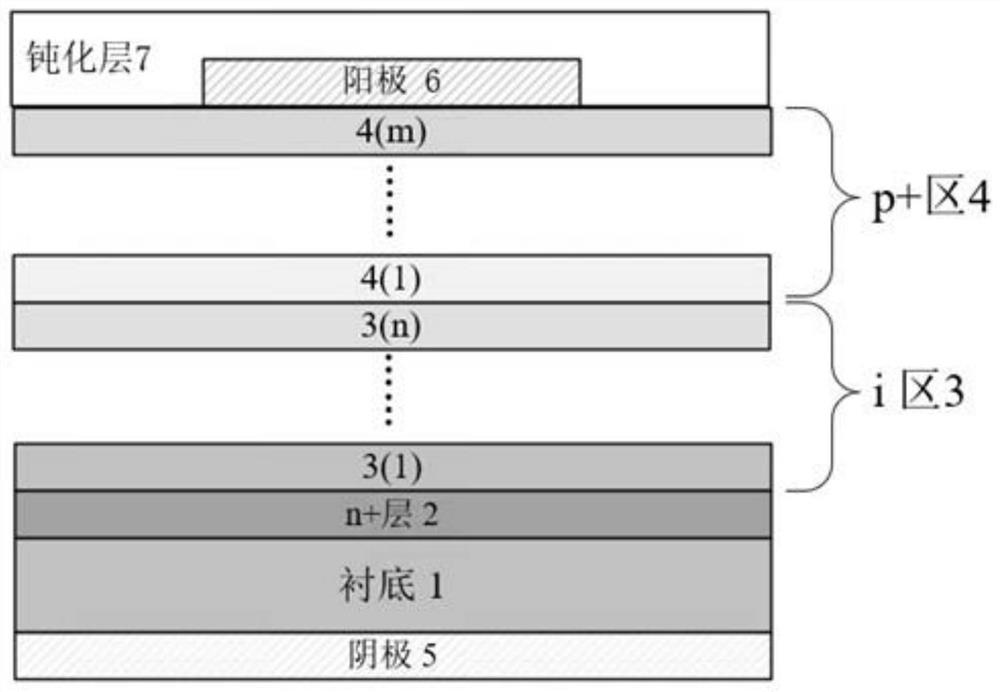

4H-SiC PIN microwave diode based on gradient doping of P region and I region and manufacturing method of 4H-SiC PIN microwave diode

A gradient doping, diode technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as being unsuitable for microwave circuits, and achieve improved power characteristics and reliability, low zero-bias junction capacitance, and low conductance. The effect of on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

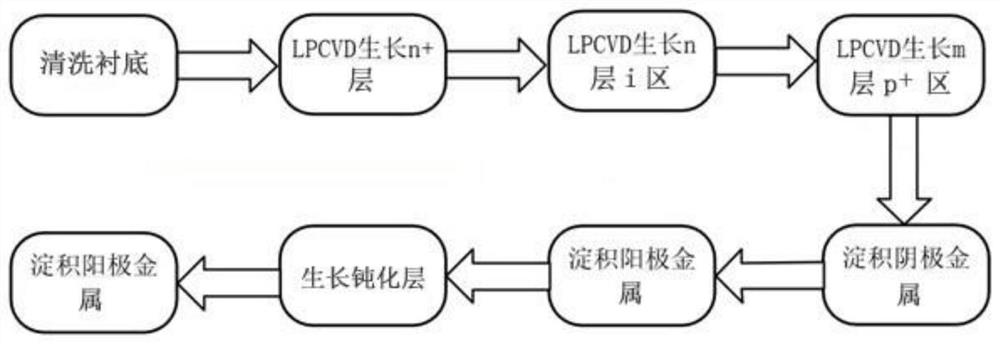

[0034] Example 1, fabricate a graded doped 4H-SiC PIN diode with a single layer thickness of 2 μm in the i region, a layer number n of 2, a single layer thickness of 0.5 μm in the p+ region, and a layer number m of 2.

[0035] In step 1, the surface of the 4H-SiC substrate is pretreated to eliminate dangling bonds.

[0036] 1.1) Boil the 4H-SiC substrate in trichlorethylene, acetone, and absolute ethanol for 10-15 min in turn, then wash with deionized water and boil for 10 min, and then in H 2 SO 4 :H 3 PO 3 =Heat 10min in the solution of 3:1, put into deionized water to clean then, to eliminate surface dangling bond;

[0037] 1.2) Use 5% HF solution to remove oxides on the surface of the cleaned substrate.

[0038] Step 2, making n+ layers.

[0039] 2.1) Put the pretreated 4H-SiC substrate into a low-pressure chemical vapor deposition LPCVD system, set the reaction chamber pressure to 10 Torr, and the temperature to 1500°C;

[0040] 2.2) Feed into the reaction chamber s...

Embodiment 2

[0056] Example 2, fabricate a gradiently doped 4H-SiC PIN diode with a single layer thickness of 2 μm in the i region, a layer number n of 3, a single layer thickness of the p+ region of 0.5 μm, and a layer number m of 2.

[0057] In step 1, the surface of the 4H-SiC substrate is pretreated to eliminate dangling bonds.

[0058] The specific implementation of this step is the same as step 1 of Embodiment 1.

[0059] Step 2, making n+ layers.

[0060] Put the pretreated 4H-SiC substrate into the low-pressure chemical vapor deposition LPCVD system, set the reaction chamber pressure to 50Torr, and the temperature to 1500°C; Hydrogen at 1500 sccm, C with a flow rate of 20 sccm 2 h 4 and SiH at a flow rate of 10 sccm 4 , grown on a 4H-SiC substrate with a thickness of 0.5 μm and a doping concentration of 10 19 cm -3 4H-SiC n+ layer.

[0061] Step 3, making multi-layer gradiently doped i-regions.

[0062] A N source with a flow rate of 70 μmol / min, a hydrogen gas with a flow ...

Embodiment 3

[0073] Example 3, fabricate a gradiently doped 4H-SiC PIN diode with a single layer thickness of 2 μm in the i region, a layer number n of 4, a single layer thickness of the p+ region of 0.5 μm, and a layer number m of 3.

[0074] In step A, the surface of the 4H-SiC substrate is pretreated to eliminate dangling bonds.

[0075] The specific implementation of this step is the same as step 1 of Embodiment 1.

[0076] Step B, making n+ layers.

[0077] B1) Put the pretreated 4H-SiC substrate into a low-pressure chemical vapor deposition LPCVD system, set the reaction chamber pressure to 100 Torr, and the temperature to 1500°C;

[0078] B2) Feed into the reaction chamber at the same time a N source with a flow rate of 100 μmol / min, a hydrogen gas with a flow rate of 2500 sccm, and a C source with a flow rate of 16 sccm. 2 h 4 and SiH at a flow rate of 8 sccm 4 , grown on a 4H-SiC substrate with a thickness of 1 μm and a doping concentration of 10 20 cm -3 4H-SiC n+ layer.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com