A light-cured degradable polyester composite guided bone regeneration membrane

A technology for guiding bone regeneration and degrading polyester. It is used in tissue regeneration, prosthesis, medical science, etc. It can solve the problem of increasing the risk of infection in the surgical area, increasing the pain and economic burden of patients, and the lack of plasticity of bone regeneration membrane. problems, to achieve the effect of controllable degradation time, improved bone regeneration ability, and no residue in the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A photocurable polycaprolactone composite guided bone regeneration film, wherein the mass ratio of magnesium powder and methacrylated polycaprolactone is 1:20, and the photoinitiator is 2,4,6-trimethylbenzyl Ethyl acylphenyl phosphonate, the mass ratio of photoinitiator to biodegradable polyester is 0.1:100, the coating ratio of methacrylated polycaprolactone and collagen is 50mg / cm 2 , The thickness of the polycaprolactone composite guiding bone regeneration membrane is 0.50mm, the surface is dense and non-porous, and the elastic modulus is 241.33±27.01MPa.

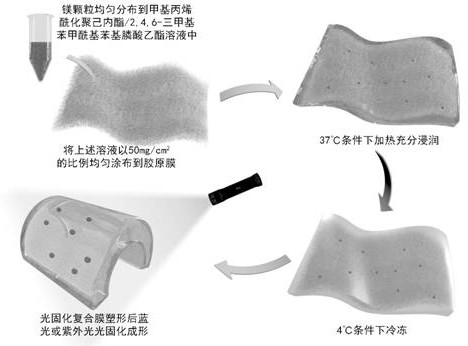

[0034] Preparation method see figure 1 , including the following steps:

[0035] ①Heat methacrylylated polycaprolactone to a molten state in a constant temperature water bath at 37°C, add photoinitiator 2,4,6-trimethylbenzoylphenylphosphonic acid ethyl ester, photoinitiator and The mass ratio of the biodegradable polyester is 0.1:100, the oscillator oscillates at a speed of 1000rmp, and the time is 15 minutes; t...

Embodiment 2

[0039] Example 2 Performance Test Method of Photocured Polycaprolactone Composite Guided Bone Regeneration Membrane

[0040] Dimensions: Measured with general measuring tools or special measuring tools, the thickness shall be measured according to the method specified in GB / T 6672-2001.

[0041] Mechanical strength: Measured according to the method specified in GB / T 130221991.

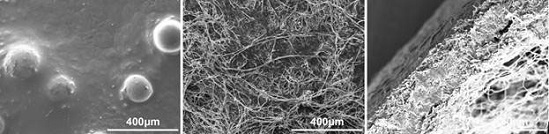

[0042] Electron micrographs of photocured polycaprolactone composite guided bone regeneration membrane figure 2 .

[0043] The thickness of the light-cured polycaprolactone composite guiding bone regeneration film can be adjusted according to the coating film ratio, the thickness is 0.30-0.60mm, and the elastic modulus is 241.33±27.01MPa.

Embodiment 3

[0044] Embodiment 3 Animal experiments

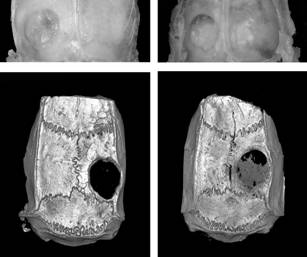

[0045] The sample obtained in Example 1 is used for rat skull defect test

[0046] Six healthy 8-week-old SD rats, male, were randomly divided into 2 groups, 3 in each group. All SD rats were raised in an SPF laboratory, ate normally, drank water freely, and adopted preoperative adaptive feeding.

[0047] After the experimental animals were anesthetized by intravenous injection, they were disinfected, the skin was cut open, and the skull was exposed. A bone defect (6mm in diameter) was prepared on the skull with a bone drill, and the photocured polycaprolactone composite guided bone regeneration film was covered on the bone defect area. (smooth side up, rough side down), moderate shaping, light curing, suturing, disinfection.

[0048] Among the two groups of animals, one group of animals was the experimental group, and the skull defect was covered with light-cured polycaprolactone composite guided bone regeneration membrane, which was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com