Layered curing forming device for composite porous buoyancy material

A technology of buoyant materials and composite materials, which is applied in the field of porous buoyant material layered solidification molding devices, can solve problems such as time-consuming and manpower-consuming, low utilization of colloids, and increased production costs, so as to reduce colloid loss, shorten production cycle, The effect of increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

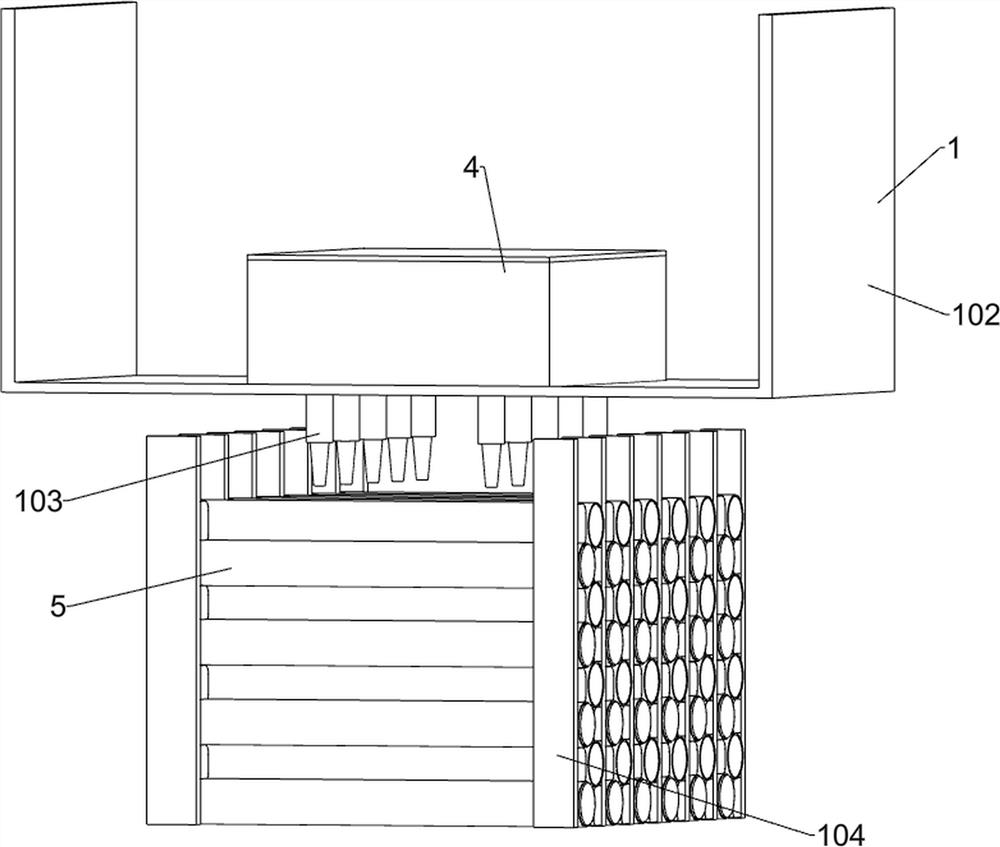

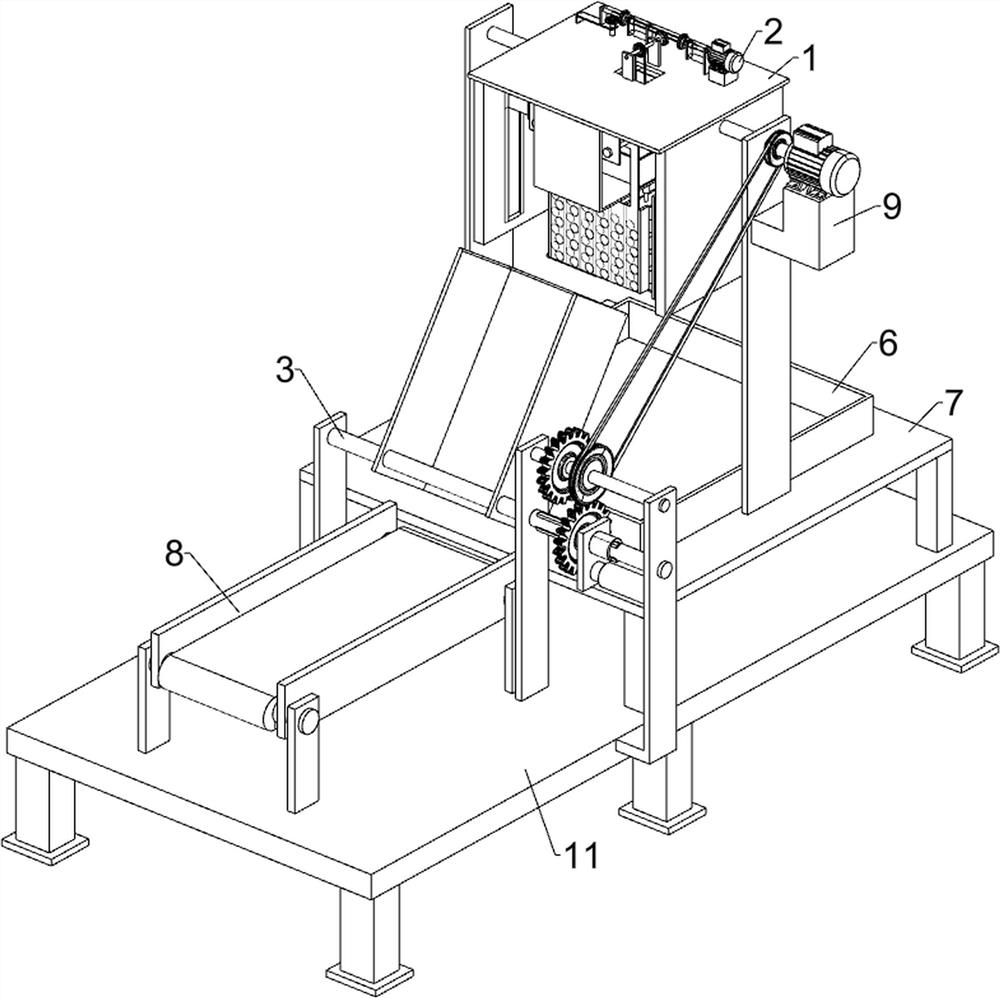

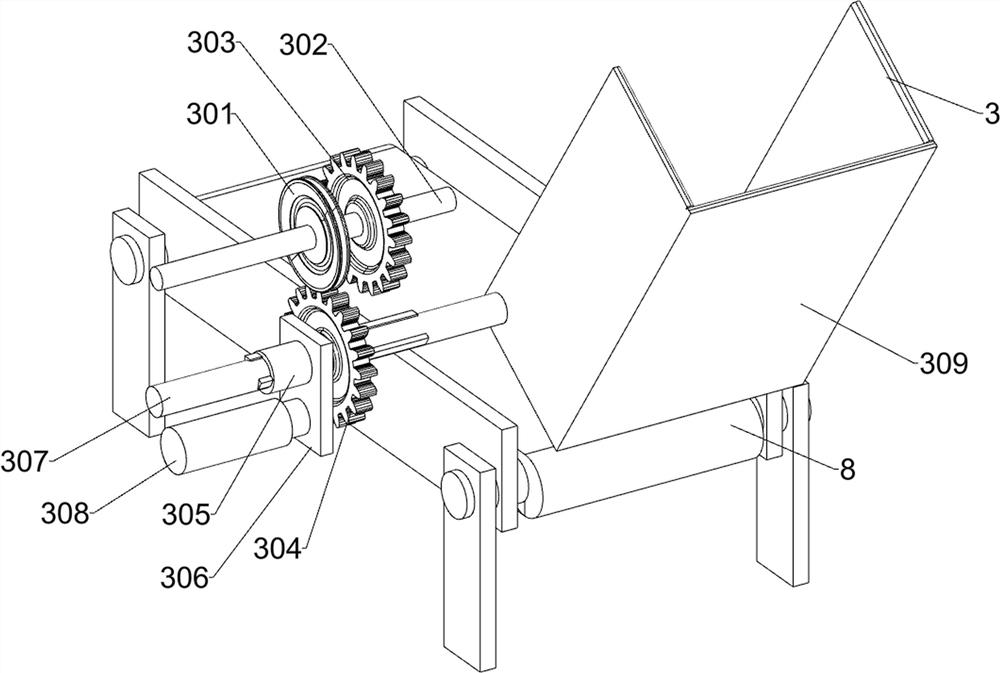

[0035] A porous buoyancy material layered solidification molding device of a composite material, such as Figure 1-14 As shown, it includes a separate glue injection mechanism 1, a molding mechanism 2, a transfer mechanism 3, a glue storage device 4, a simulated carbon fiber round tube 5, a glue collection frame 6, a placement frame 7, a conveyor belt 8, a fixed block 9, a controller 10 and Fixing frame 11; separated glue injection mechanism 1 is connected with forming mechanism 2; separated glue injection mechanism 1 is connected with glue storage device 4; separated glue injection mechanism 1 is connected with simulated carbon fiber round tube 5; forming mechanism 2 is connected with transfer mechanism 3 connected; molding mechanism 2 is connected with placement frame 7; molding mechanism 2 is connected with fixed block 9; transfer mechanism 3 is connected with fixed frame 11; placement frame 7 is connected with colloid collection frame 6; placement frame 7 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com