Preparation process of ethylene sulfate

A technology for the preparation of vinyl sulfate, which is applied in the direction of organic chemistry, can solve the problems of low yield and difficulty in fully carrying out the reaction, and achieve the effects of increased product yield, short reaction route, low cost of raw and auxiliary materials and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

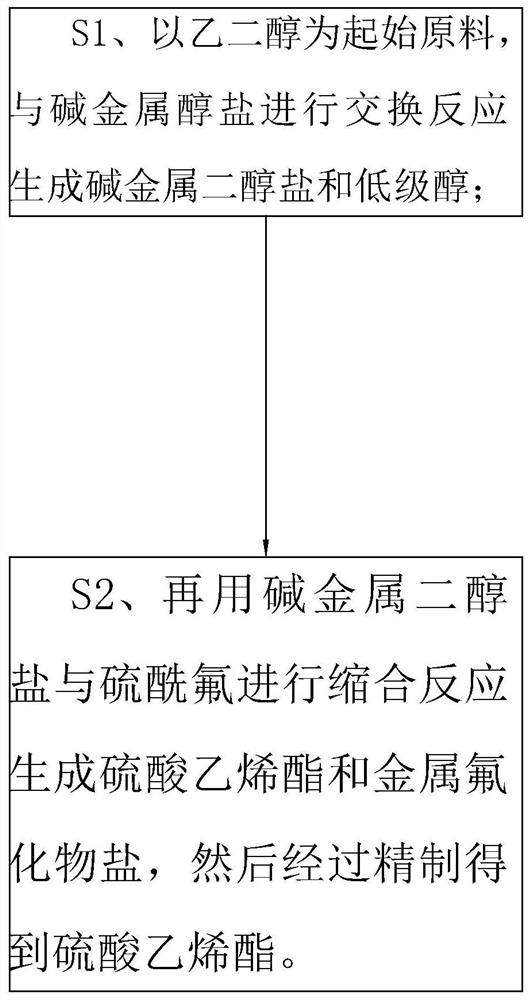

Method used

Image

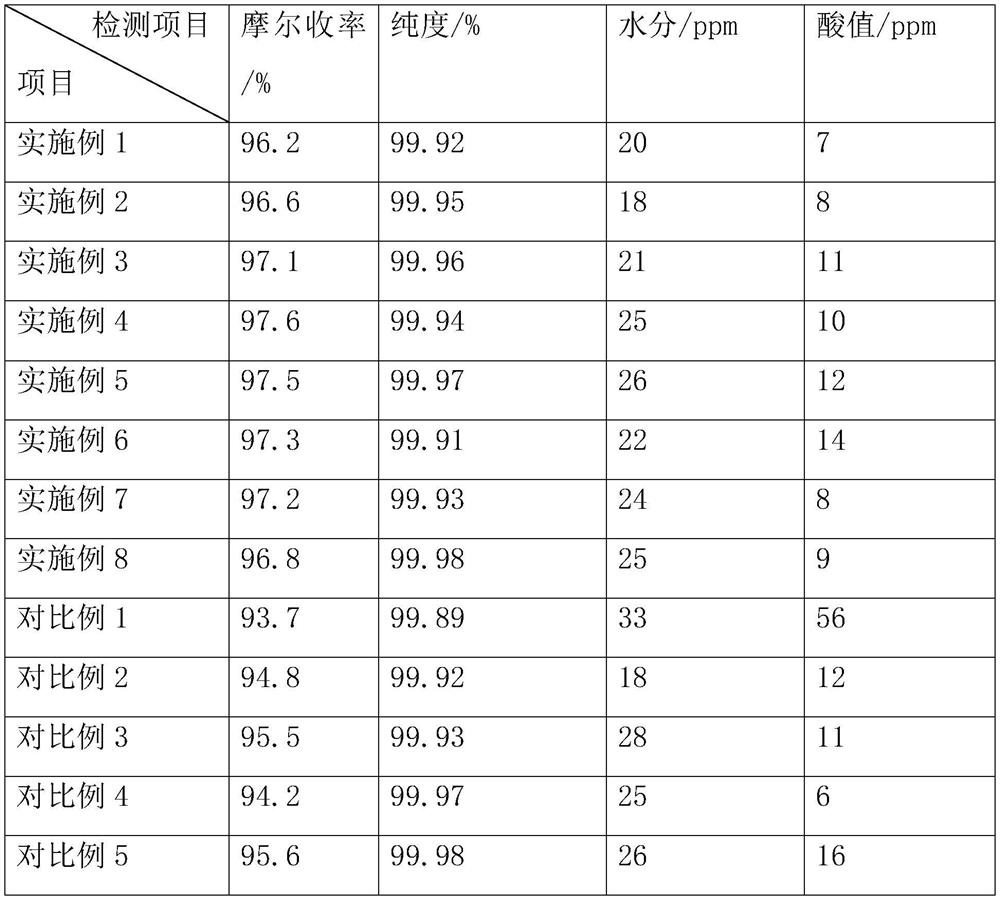

Examples

Embodiment 1

[0037] A kind of preparation technology of vinyl sulfate, comprises the following steps:

[0038] S1. Add 100kg of ethylene glycol weighed into the synthesis reaction kettle, then add 180kg of sodium ethoxide into the synthesis reaction kettle, then stir for 2 hours to mix evenly, and control the temperature in the reaction kettle to 0°C;

[0039] S2. Feed 120 kg of sulfuryl chloride into the reaction solution in S1. The speed of sulfuryl chloride feeding is 22 mL / min, and the pressure of feeding is 0.3-0.4 MPa. After reacting for 2 hours, blow nitrogen gas for 1 hour, and stir again for 2.5 hours. After standing still for 0.5h, the mixture of vinyl sulfate and metal chloride salt generated was separated to obtain crude vinyl sulfate, and the crude product of vinyl sulfate was dehydrated with anhydrous magnesium sulfate, and after dehydration, dichloroethane was used to dehydrate the crude product of vinyl sulfate. The crude product of vinyl sulfate is recrystallized, wherein ...

Embodiment 2

[0041] S1. Add 100kg of ethylene glycol weighed into the synthesis reaction kettle, then add 180kg of sodium ethoxide into the synthesis reaction kettle, then stir for 2 hours to mix evenly, and control the temperature in the reaction kettle to 5°C;

[0042] S2, feed 160 kg of sulfuryl chloride into the reaction solution in S1, the feed rate of sulfuryl chloride is 22mL / min, the pressure of feed is 0.3-0.4MPa, after reacting for 2h, blow nitrogen gas for 1h, and stir again for 2.5h, After standing still for 0.5h, the mixture of vinyl sulfate and metal chloride salt generated was separated to obtain crude vinyl sulfate, and the crude product of vinyl sulfate was dehydrated with anhydrous magnesium sulfate, and after dehydration, dichloroethane was used to dehydrate the crude product of vinyl sulfate. The crude product of vinyl sulfate is recrystallized, wherein the weight ratio of ethylene dichloride and vinyl sulfate is 1.5:1, and finally vacuum-dried to obtain high-purity viny...

Embodiment 3

[0044] S1. Add 100kg of ethylene glycol weighed into the synthesis reaction kettle, then add 215kg of sodium ethoxide into the synthesis reaction kettle, then stir for 2 hours to mix evenly, and control the temperature in the reaction kettle to 5°C;

[0045]S2. Introduce 160kg of sulfuryl fluoride into the reaction liquid in S1. The rate of introduction of sulfuryl fluoride is 22mL / min, and the pressure of introduction is 0.3-0.4MPa. After 2.5h of reaction, blow nitrogen gas for 1.5h and stir again React for 3h, after standing for 1h, separate the mixture of vinyl sulfate and metal fluoride salts to obtain the crude vinyl sulfate, use anhydrous magnesium sulfate to dehydrate the crude vinyl sulfate, and use dichloroethane to dehydrate the crude product after dehydration The vinyl sulfate crude product after dehydration carries out recrystallization, and wherein the weight ratio of ethylene dichloride and vinyl sulfate is 1.5:1, carries out vacuum drying at last and obtains high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com