A kind of electric double layer type polyacrylamide microsphere and preparation method thereof

A polyacrylamide and acrylamide technology, which is applied to chemical instruments and methods, drilling compositions and other directions, can solve the problems of limited water absorption and expansion ratio, environmental pollution by organic phase, poor stability, etc., and achieves low cost and good stability. , easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

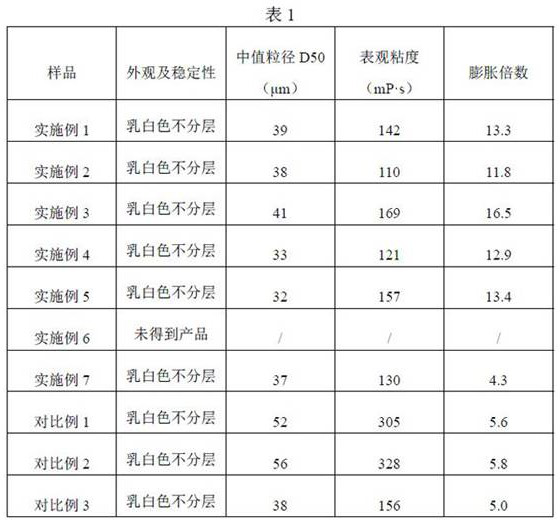

Examples

Embodiment 1

[0076] In this example, polyacrylamide microspheres with an electric double layer structure were prepared by the following method.

[0077] (1) Mix 130g of acrylamide crystals, 50g of acryloyloxyethyl dimethyl benzyl ammonium chloride, 8g of 2-acrylamido-12-alkylsulfonic acid, 80g of self-made dispersant A, 0.02g N , N -Methylenebisacrylamide, 170g of ammonium sulfate, and 562g of deionized water are fully mixed and dissolved, adjusted to a pH of 6.0, transferred to a reaction kettle, sealed and blown with nitrogen for 30 minutes to remove oxygen, and the initial temperature of the reaction is controlled by a water bath to 20°C. Add 0.05g sodium diethylenetriaminepentaacetate, 0.005g sodium formate, 0.05g azobisisobutylamidine hydrochloride, 0.01g potassium persulfate, 0.012g sodium bisulfite, and stir at 250 r / min to induce free radicals Polymerization, as the reaction progressed, the temperature was raised to 45°C at a uniform rate within 1.2h and kept for 1h.

[0078] (2)...

Embodiment 2

[0081] In this example, electric double layer polyacrylamide microspheres were prepared by the following method.

[0082] (1) Mix 120g of acrylamide crystals, 46.2g of acryloyloxyethyl dimethyl benzyl ammonium chloride, 7.4g of 2-acrylamido-12-alkylsulfonic acid, 73.8g of self-made dispersant A, 0.018g N , N -Methylenebisacrylamide, 175g of ammonium sulfate, and 576g of deionized water are fully mixed and dissolved, adjusted to a pH of 6.2, transferred to a reaction kettle, sealed and blown with nitrogen for 30 minutes to remove oxygen, and the initial temperature of the reaction is controlled by a water bath to 20°C. Add 0.05g sodium diethylenetriaminepentaacetate, 0.005g sodium formate, 0.05g azobisisobutylamidine hydrochloride, 0.01g potassium persulfate, 0.012g sodium bisulfite, stir at a speed of 200-300r / min, and trigger the free base polymerization, as the reaction progressed, the temperature was raised to 45°C at a uniform rate within 1.2h and kept for 1h.

[0083] (...

Embodiment 3

[0086] In this example, electric double layer polyacrylamide microspheres were prepared by the following method.

[0087] (1) Mix 140g of acrylamide crystals, 53.8g of acryloyloxyethyl dimethyl benzyl ammonium chloride, 8.6g of 2-acrylamido-12-alkylsulfonic acid, 86.2g of self-made dispersant A, 0.022g N , N -Methylenebisacrylamide, 165g of ammonium sulfate, and 546g of deionized water were fully mixed and dissolved, adjusted to a pH of 6.0, transferred to a reaction kettle, sealed and blown with nitrogen for 30 minutes to remove oxygen, and the initial temperature of the reaction was controlled by a water bath to 20°C. Add 0.05g sodium diethylenetriaminepentaacetate, 0.005g sodium formate, 0.05g azobisisobutylamidine hydrochloride, 0.01g potassium persulfate, 0.012g sodium bisulfite, stir at a speed of 200-300r / min, and trigger the free base polymerization, as the reaction progressed, the temperature was raised to 45°C at a uniform rate within 1.2h and kept for 1h.

[0088]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com