Method for recovering rhenium from molybdenum smelting waste acid by using secondary amine impregnated resin

A technology of impregnating resin and secondary amines, which is applied in the field of hydrometallurgy and comprehensive recovery of secondary resources, can solve the problem of high reagent consumption, achieve the effects of reducing the loss of secondary amines, high enrichment ratio, and good adsorption treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

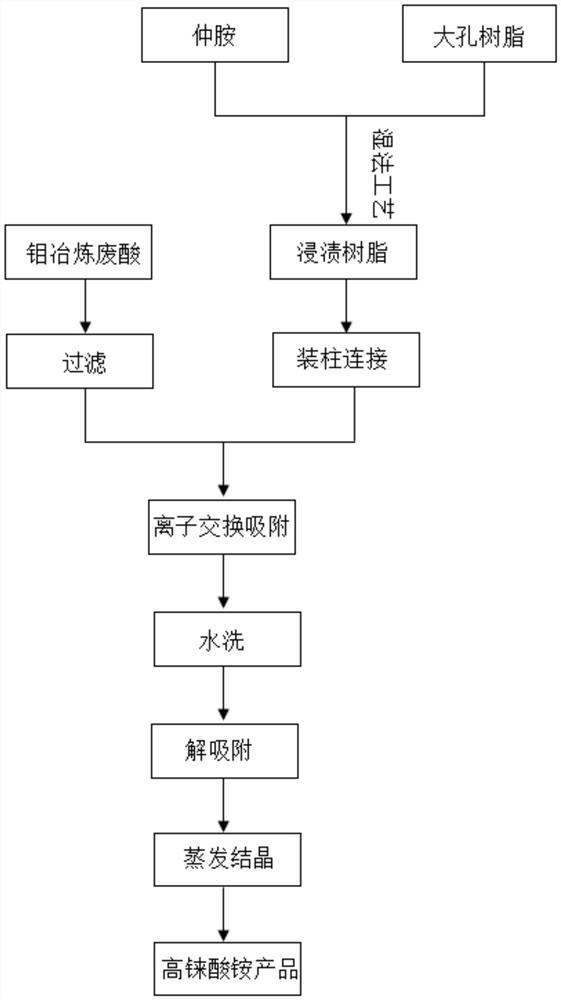

Method used

Image

Examples

Embodiment 1

[0021] The secondary amine impregnated resin of the present embodiment is made by the preparation method comprising the following steps:

[0022] At room temperature, di-n-octylamine was dissolved in dichloromethane to prepare a solution with a mass percent concentration of 10%; a certain amount of Amberlite XAD-4 resin was soaked in the above-mentioned organic solvent containing secondary amine, and the reaction was completed after shaking for 24 hours. After filtering, and washing with ethanol for 3 times, the resin was vacuum-dried at 50°C to obtain impregnated resin 1.

[0023] Adopt above-mentioned impregnation resin 1 to reclaim rhenium from the waste acid of molybdenum smelting (get the waste acid of molybdenum smelting and carry out component analysis, record S 49g / L, Mo 582mg / L, Re 48mg / L, F 12.1g / L in the acid liquid), Include the following steps:

[0024] 1) Take 1L of impregnation resin 1 prepared above and put them into 4 ion exchange columns connected in series ...

Embodiment 2

[0029] The secondary amine impregnated resin of the present embodiment is made by the preparation method comprising the following steps:

[0030] At room temperature, dissolve diisooctylamine in ethanol to prepare a solution with a concentration of 15% by mass; soak a certain amount of Amberlite XAD-7HP resin in the above-mentioned organic solvent containing secondary amine, shake for 20 hours, and filter after the reaction , and washed with ethanol three times, and the resin was vacuum-dried at 50°C to obtain impregnated resin 2.

[0031] Recover rhenium from molybdenum smelting waste acid by adopting above-mentioned impregnating resin 2, (get molybdenum smelting waste acid and carry out component analysis, record S 49g / L, Mo 582mg / L, Re 48mg / L, F 12.1g / L in the acid solution) Include the following steps:

[0032] 1) Take 1L of the above-prepared impregnation resin 2 and put them into 4 ion-exchange columns connected in series (each column is filled with 0.25L of ion-exchang...

Embodiment 3

[0037] The secondary amine impregnated resin of the present embodiment is made by the preparation method comprising the following steps:

[0038]At room temperature, di-n-quinylamine was dissolved in acetone to prepare a solution with a mass percent concentration of 10%; a certain amount of Amberlite XAD-16 resin was soaked in the above-mentioned organic solvent containing secondary amines, shaken for 24 hours, and filtered after the reaction was completed. And washed with ethanol for 3 times, and the resin was vacuum-dried at 50°C to obtain impregnated resin 3.

[0039] Recover rhenium from molybdenum smelting waste acid by adopting above-mentioned impregnating resin 3, (take molybdenum smelting waste acid and carry out component analysis, record S 49g / L, Mo 582mg / L, Re 48mg / L, F 12.1g / L in the acid solution) Include the following steps:

[0040] 1) Take 1L of impregnation resin 3 prepared above and put them into 4 ion exchange columns connected in series (each column is fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com