Membrane material for multi-layer co-extrusion disposable biotechnological bag

A one-time, membrane material technology, applied in the direction of biomass post-treatment, biomass pre-treatment, biochemical cleaning equipment, etc., can solve the problems of high hygroscopicity and poor barrier effect, and achieve strong puncture resistance, easy operation, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Multi-layer co-extrusion film material for disposable biotechnology bags prepared by co-extrusion casting method

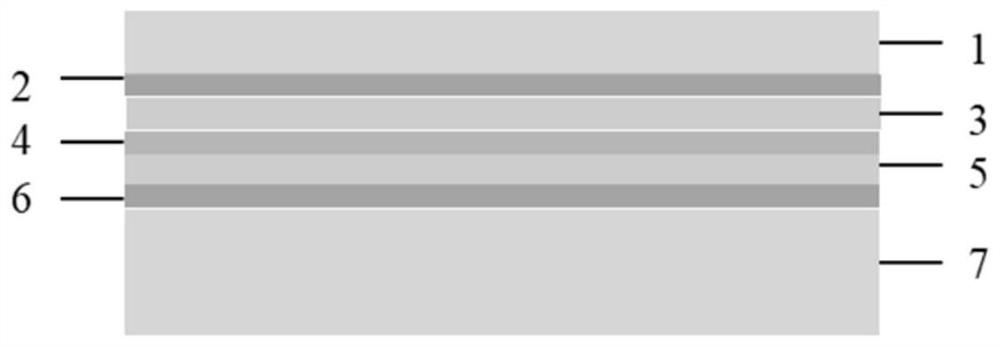

[0050] In this example, the co-extrusion casting method is used to prepare a disposable biotechnology bag film with a thickness of 325 μm. The composition and structure of the film include the following: figure 1 As shown, it includes protective layer 1, adhesive layer 2, gas barrier layer 3 / 4 / 5, adhesive layer 6 and liquid contact layer 7.

[0051] Among them, the protective layer is a mixture of LDPE and LLDPE, LDPE accounts for 30%, and LLDPE accounts for 70%. LDPE adopts Dow's DOW series, LLDPE adopts American Dow's DOW, and the thickness of this layer is 50 μm.

[0052] Wherein the adhesive layers 2 and 6 are made of EVA, and the EVA is made of Celanese EVA, and the thickness of this layer is 10 μm.

[0053] The gas barrier layers 3 and 5 are aromatic PA, which are made by American DuPont, and the thickness of the layers is 20 μm.

[0054...

Embodiment 2

[0069] Example 2 The multi-layer co-extrusion disposable biotechnology bag film material prepared by co-extrusion casting method

[0070] In this example, the co-extrusion casting method is used to prepare a disposable biotechnology bag film with a thickness of 305 μm. The composition of the film includes the following figure 2 As shown, a protective layer 8 , an adhesive layer 9 , a gas barrier layer 10 / 11 , an adhesive layer 12 and a liquid contact layer 13 are included.

[0071] Wherein the protective layer 8 is a mixture of LDPE and LLDPE, LDPE accounts for 30%, and LLDPE accounts for 70%. LDPE adopts Dow series of Dow, LLDPE adopts American Dow DOW, and the thickness of this layer is 50 μm.

[0072] Wherein the adhesive layers 9 and 12 are made of EVA, the EVA is made of Celanese EVA, and the thickness of this layer is 10 μm.

[0073] The gas barrier layer 10 is aromatic PA, which adopts the relevant brand of DuPont in the United States, and the thickness of this lay...

Embodiment 3

[0084] Example 3 Effects of Different Liquid Contact Layers on the Performance of Disposable Bioprocess Bags

[0085] In this example, the disposable bioprocess bag film material is prepared according to the method of Example 1, that is, PA / EVOH / PA is used as the gas barrier layer, and the LDPE:LLDPE is a mixture of 3:7 to prepare the protective layer, according to the method provided in Example 1 Prepare the film material for disposable biotechnology bags, and adopt the liquid contact layer shown in Table 3 respectively, wherein the thickness is the thickness of the liquid contact layer, investigate the obtained multilayer co-extruded disposable biotechnology bag film material Dissolution of small molecule substances, oxygen, water vapor permeability, tensile strength, puncture resistance, transparency and cell culture effect (biocompatibility).

[0086] Both LDPE and LLDPE use American Dow DOW; ULDPE uses Dow Chemical Engage 8480K series ULDPE.

[0087] Wherein, the detecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com