Fluorescent ceramic with high color rendering index and high thermal stability for white light illumination and preparation method of fluorescent ceramic

A high thermal stability, fluorescent ceramic technology, applied in the field of fluorescent ceramic materials, can solve the problems of decreased thermal stability, decreased thermal stability of fluorescent ceramics, and high manufacturing costs, and achieves enhanced absorption strength, high thermal stability, and high emission intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

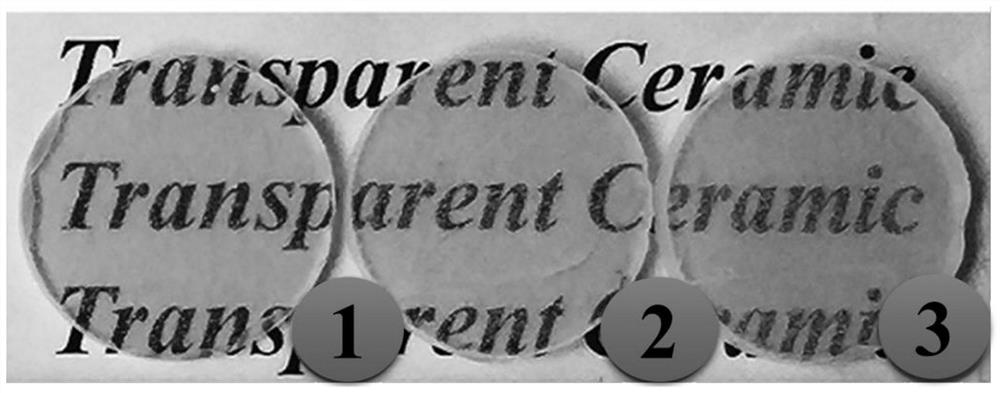

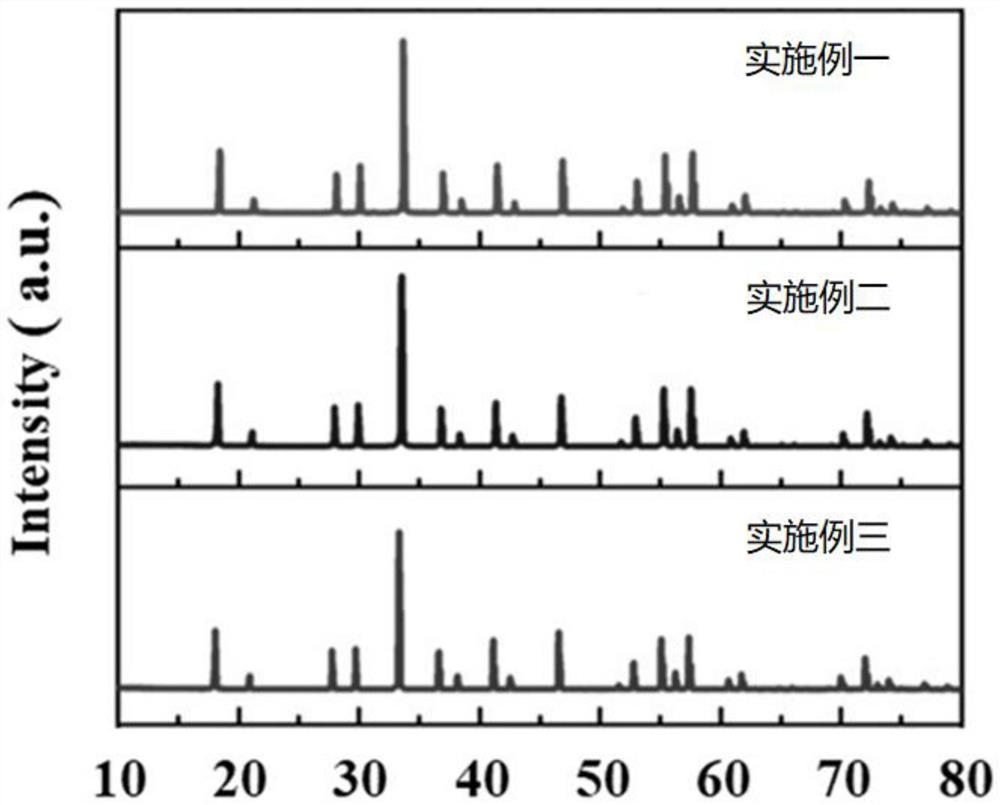

Embodiment 1

[0031] The preparation chemical formula is (Lu 0.988 Ce 0.002 Bi 0.01 ) 3 (Al 0.998 mn 0.002 ) 5 o 12 fluorescent ceramics.

[0032] (1) Set the target product quality as 60.029g, according to the chemical formula (Lu 0.988 Ce 0.002 Bi 0.01 ) 3 (Al 0.998 mn 0.002 ) 5 o 12 The stoichiometric ratio of each element in α-lutetium oxide (41.487g), aluminum oxide (17.896g), bismuth oxide (0.492g), manganese carbonate (0.081g) and cerium oxide (0.073g) were weighed as raw material powder ;

[0033] (2) Mix the above-mentioned various raw material powders with 200mL of absolute ethanol, and additionally add a charge compensator (0.003g). The charge compensator is nano-spherical silica with an average particle size of 1nm, which is obtained by ball milling in a ball mill tank For the mixed slurry, the ball milling speed is 190r / min, and the ball milling time is 16h; the molar ratio between nano-spherical silica and manganese carbonate is 0.07:1; the mixed slurry is drie...

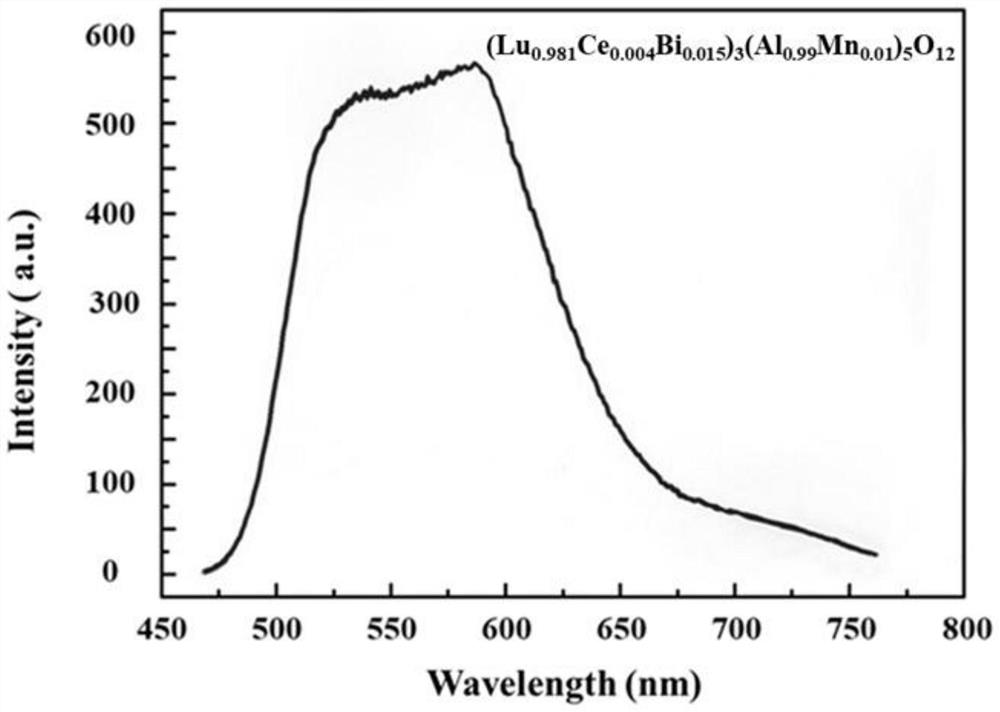

Embodiment 2

[0040] The preparation chemical formula is (Lu 0.981 Ce 0.004 Bi 0.015 ) 3 (Al 0.99 mn 0.01 ) 5 o 12 fluorescent ceramics.

[0041] (1) Set the target product quality as 60.133g, according to the chemical formula (Lu 0.981 Ce 0.004 Bi 0.015 ) 3 (Al 0.99 mn 0.01 ) 5 o 12 The stoichiometric ratio of each element in α-lutetium oxide (41.125g), aluminum oxide (17.723g), bismuth oxide (0.736g), manganese carbonate (0.404g) and cerium oxide (0.145g) were weighed as raw material powder ;

[0042] (2) Mix the above-mentioned various raw material powders with 200mL of absolute ethanol, and additionally add a charge compensator (0.852g). The charge compensator is nano-spherical silica with an average particle size of 3nm, which is obtained by ball milling in a ball mill tank For the mixed slurry, the ball milling speed is 190r / min, and the ball milling time is 16h; the molar ratio between nano-spherical silica and manganese carbonate is 4:1; the mixed slurry is dried in ...

Embodiment 3

[0049] The preparation chemical formula is (Lu 0.964 Ce 0.006 Bi 0.03 ) 3 (Al 0.98 mn 0.02 ) 5 o 12 fluorescent ceramics.

[0050] (1) Set the target product quality as 60.261g, according to the chemical formula (Lu 0.964 Ce 0.006 Bi 0.03 ) 3 (Al 0.98 mn 0.02 ) 5 o 12 The stoichiometric ratio of each element in α-lutetium oxide (40.283g), aluminum oxide (17.489g), bismuth oxide (1.468g), manganese carbonate (0.805g) and cerium oxide (0.216g) were weighed as raw material powder ;

[0051] (2) Mix the above-mentioned various raw material powders with 200mL of absolute ethanol, and additionally add a charge compensator (2.063g). The charge compensator is nano-spherical silica with an average particle size of 5nm, which is obtained by ball milling in a ball mill tank For the mixed slurry, the ball milling speed is 200r / min, and the ball milling time is 20h; the molar ratio between nano-spherical silica and manganese carbonate is 5:1; the mixed slurry is dried in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| spectroscopy | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com