Moderately crosslinked starch biodegradable plastic and preparation method thereof

A technology of biodegradable plastic and cross-linked starch, applied in the field of moderately cross-linked starch biodegradable plastic and its preparation, can solve the problems of decreased mechanical properties, brittle texture of PLA, long degradation period, etc. Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

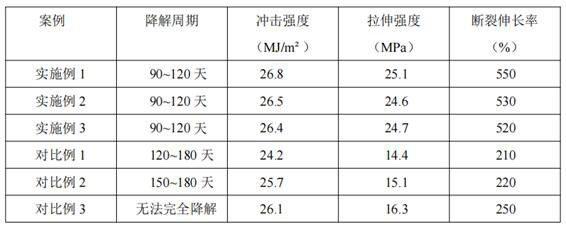

Examples

Embodiment 1

[0027] A moderately crosslinked starch biodegradable plastic, the biodegradable plastic is made of the following raw materials in parts by weight: 20 parts of biodegradable resin, 20 parts of starch, 5 parts of organic fiber powder, 5 parts of inorganic filler powder, and 5 parts of crosslinking agent , 5 parts of plasticizer, 1 part of lubricant, 0.5 part of antioxidant, 0.5 part of coupling agent.

[0028] A method for preparing moderately cross-linked starch biodegradable plastics, comprising the following steps:

[0029] (1) Preparation of cross-linked starch: Weigh 20 parts of starch and appropriate amount of water in parts by weight and add to a high-speed mixer to stir evenly to prepare 40% starch milk, add 5 parts of cross-linking agent, and use 0.1mol / L Adjust the pH of the sodium hydroxide solution to 10. After reacting at a temperature of 45°C for 15 minutes, adjust the pH of the system to 6 with dilute hydrochloric acid with a concentration of 0.1mol / L, adjust the ...

Embodiment 2

[0035] A moderately cross-linked starch biodegradable plastic, the biodegradable plastic is made of the following raw materials in parts by weight: 50 parts of biodegradable resin, 50 parts of starch, 20 parts of organic fiber powder, 20 parts of inorganic filler powder, and 10 parts of crosslinking agent , 10 parts of plasticizer, 3 parts of lubricant, 1 part of antioxidant, 1 part of coupling agent.

[0036] A method for preparing moderately cross-linked starch biodegradable plastics, comprising the following steps:

[0037] (1) Preparation of cross-linked starch: Weigh 50 parts of starch and appropriate amount of water in parts by weight and add it to a high-speed mixer to stir evenly to prepare 40% starch milk, add 10 parts of cross-linking agent, and use a concentration of 0.1mol / L Adjust the pH of the sodium hydroxide solution to 10.5. After reacting at a temperature of 50°C for 25 minutes, adjust the pH of the system to 6.5 with a concentration of 0.1mol / L dilute hydroc...

Embodiment 3

[0043] A moderately cross-linked starch biodegradable plastic, the biodegradable plastic is made of the following raw materials in parts by weight: 80 parts of biodegradable resin, 80 parts of starch, 40 parts of organic fiber powder, 40 parts of inorganic filler powder, and 20 parts of crosslinking agent , 20 parts of plasticizer, 5 parts of lubricant, 2 parts of antioxidant, 2 parts of coupling agent.

[0044] A method for preparing moderately cross-linked starch biodegradable plastics, comprising the following steps:

[0045] (1) Preparation of cross-linked starch: Weigh 80 parts of starch and appropriate amount of water according to parts by weight and add it to a high-speed mixer to stir evenly to prepare 40% starch milk, add 20 parts of cross-linking agent, and use 0.1mol / L Adjust the pH of the sodium hydroxide solution to 11, react at a temperature of 60°C for 40 minutes, adjust the pH of the system to 7 with a concentration of 0.1mol / L dilute hydrochloric acid, adjust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com