Construction of corynebacterium glutamicum independent of antibiotics and capable of efficiently producing gamma-aminobutyric acid

A technology of Corynebacterium glutamicum and aminobutyric acid, applied in the field of genetic engineering and microbial fermentation, can solve the problems of increased production costs, non-conforming to green production, environmental pollution caused by antibiotics, etc., and achieve the effect of stable production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

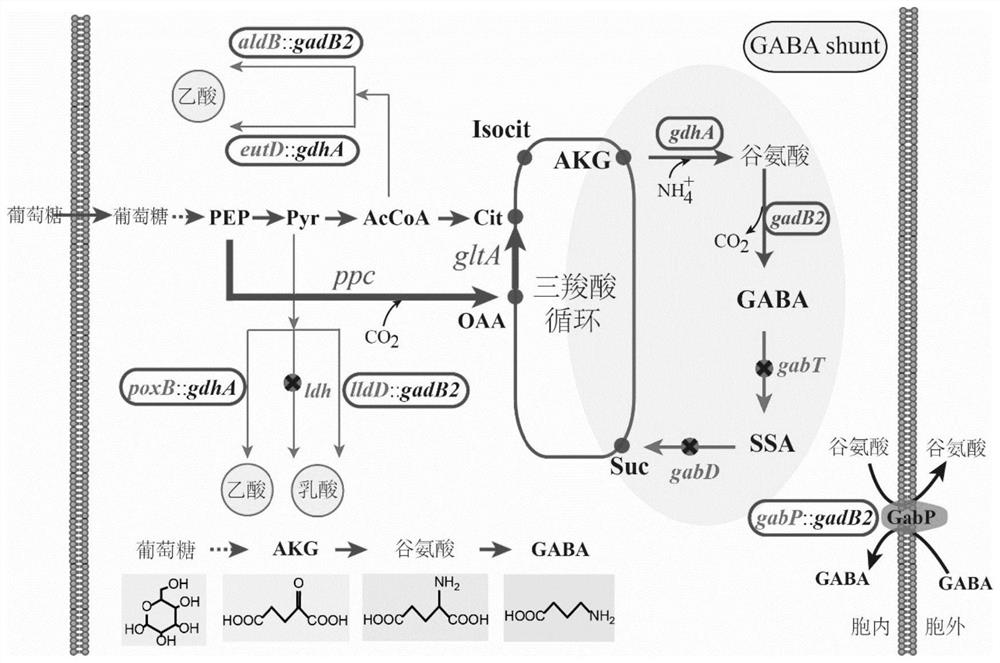

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: Construction of recombinant plasmid

[0052] (1) Construction of gabB2 inserted into the recombinant plasmid in gabP:

[0053] Using primers gabPsg-F / sgRNA-R, gabP-U-F / gabP-U-R and gabP-D-F / gabP-D-R, using plasmid pBS-sgRNA and Corynebacterium glutamicum ATCC13032 genome as templates, 3 fragments were amplified; PgadB2-F1 / PgadB2-R as primers, plasmid pJYW-5-gadB2-gadB1 mut For the template clone obtained containing the promoter P tacM gabP-F / gabP-D-R using primers gabP-F / gabP-D-R to fuse the above four fragments into one fragment by fusion PCR, and use this fragment with the pCCG1 plasmid obtained by digestion with BamH I-Afl II II One Step Cloning Kit connection, the connection product was introduced into E.coli DH5α by chemical transformation method, the transformation solution was spread on the LB plate containing 30 mg / L kanamycin, cultured at 37°C until a single colony grew, and picked A single colony was taken for PCR verification and sequencing,...

Embodiment 2

[0078] Embodiment 2: Construction of recombinant bacterial strain

[0079] (1) The plasmid pCCG1-gabP::gadB2 constructed in Example 1 was transformed into Corynebacterium glutamicum ATCC 13032 by electroporation, and the genome was edited to obtain the recombinant strain CGY100 (ATCC 13032, gabP::gadB2) . For the detailed preparation process and molecular operation of competent cells, please refer to the literature of this laboratory: Yao C, Hu X, Wang X. 2021. Construction and application of a CRISPR / Cas9-assisted genomic editing system for Corynebacterium glutamicum. AMB Expr 11.

[0080] (2) According to the same method as (1), the gene gabTD was knocked out using the plasmid pCCG1-△gabTD (Yao et al. 2021) to obtain strain CGY101.

[0081] (3) According to the same method as (1), the plasmids pCCG1-eutD::gdhA, pCCG1-poxB::gdhA, pCCG1-lldD::gadB2, pCCG1-aldB2::gadB2 were used to continuously edit CGY101 to obtain strain CGY700.

[0082] (4) According to the same method as ...

Embodiment 3

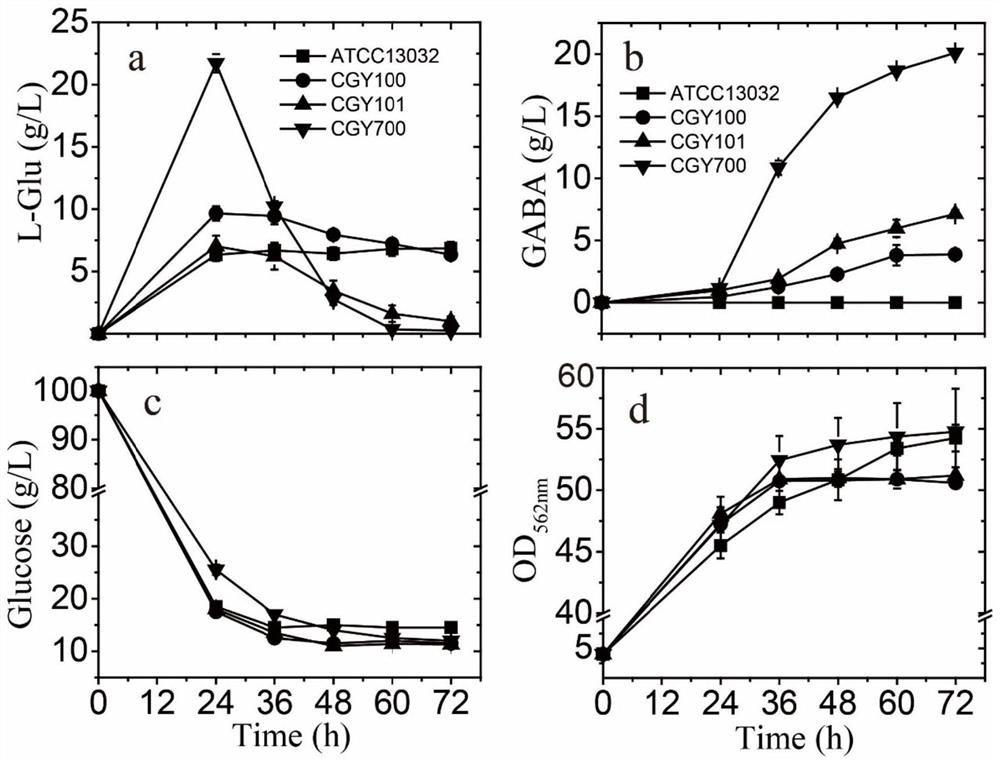

[0086] Embodiment 3: recombinant bacterial fermentation produces GABA

[0087] (1) GABA production method by shake flask fermentation

[0088] Inoculate the strain constructed in Example 2 into a liquid LBHIS test tube, culture at 30°C, 200rpm for 12-14 hours, and then inoculate 0.2mL of the culture into a 500mL Erlenmeyer flask with baffles containing 30mL of seed medium, at 30°C , cultivated at 200rpm for 8-10 hours until the optical density value reached OD 562nm 40±3, to obtain seed solution. Take 3mL (10%) seed solution and inoculate in a 500mL size baffle Erlenmeyer flask containing 30mL fermentation medium, ferment and cultivate for 72 hours at 30°C and 200rpm. Add 0.4, 0.24, 0.24, 0.24, 0.24, 0.24mL of 300g / L urea at 0, 10, 13, 16, 19, 22 hours of fermentation respectively. Urea is the main nitrogen source and pH regulator for fermentation, and the total amount of urea added in shake flask fermentation is 16g / L.

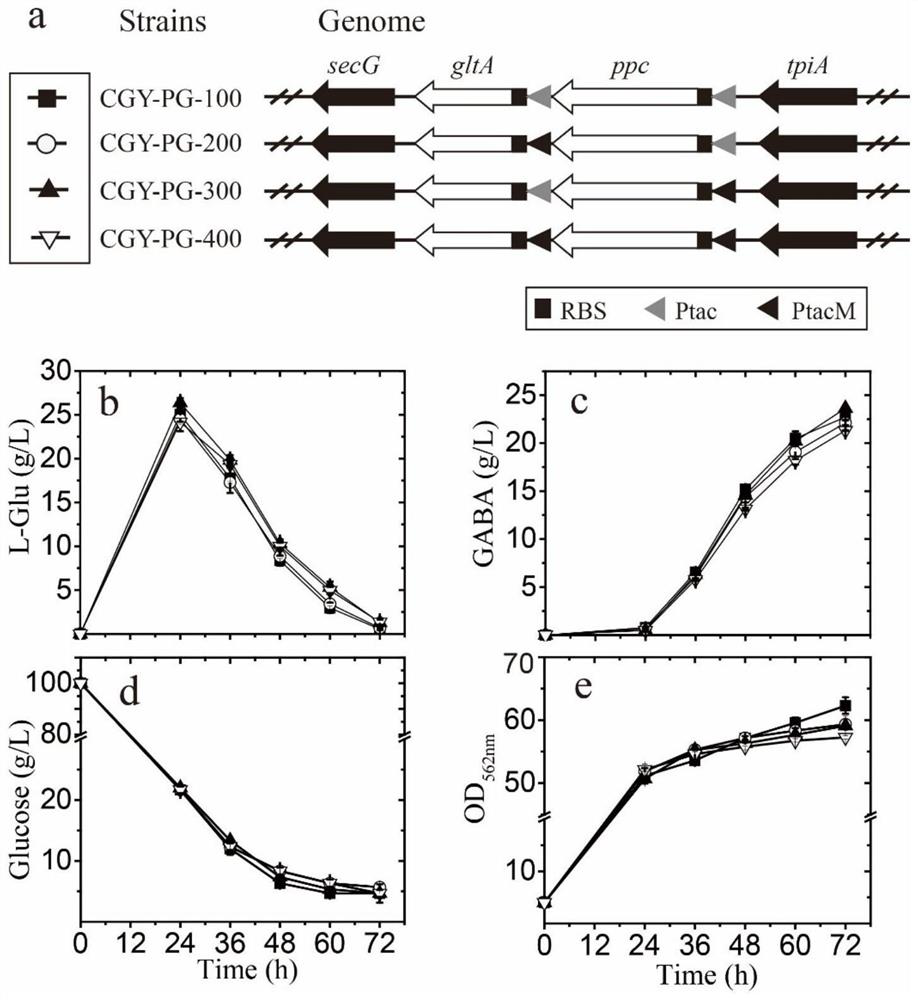

[0089] The result is as figure 2 and image 3 S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com