Precise hollow RV speed reducer

A reducer, hollow technology, applied in the field of precision hollow RV reducer, can solve the problems of easy noise accuracy retention, easy heat generation, easy vibration, etc., to achieve good dynamic characteristics, easy assembly, and small vibration effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

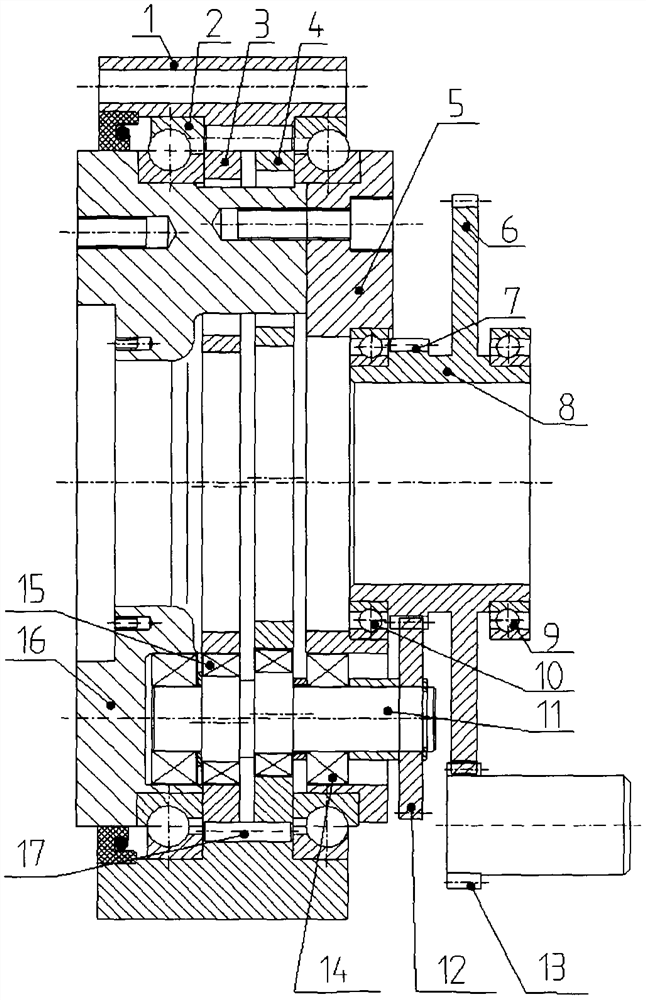

[0048] A precision hollow RV reducer, which includes a pin gear housing 1 and two-stage reduction components placed therein:

[0049] The first-stage deceleration part comprises the driving wheel 13 on the servo motor, the double gear 8 and 2 or 3 evenly distributed planetary gears 12, and the double gear 8 includes the driven wheel 6 and the sun gear 7, the driven wheel 6 and the driving wheel. The gear 13 meshes, the sun gear 7 meshes with the planetary gear 12, and the planetary gear 12 is connected to the eccentric shaft 11 shaft extension end of the second-stage reduction component. The first bearing 10 and the second bearing 9 are respectively supported on the corresponding positions of the right rigid disc 5 and the robot body;

[0050] The second-stage deceleration components include uniformly distributed eccentric shaft 11, cycloidal wheel, pin 17, left and right rigid disks, and bearings. The center holes of the left and right rigid disks are evenly distributed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com