Gradient degradation medical sponge and preparation method thereof

A sponge and gradient technology, which is applied in the field of medical sponges, can solve problems such as the difficulty in transporting the bleeding point of the cavity to the bleeding position, sponge chipping, and difficulty in precision machining, etc., and achieve the effects of wound pressure to stop bleeding, isolate the wound, and prevent wound adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

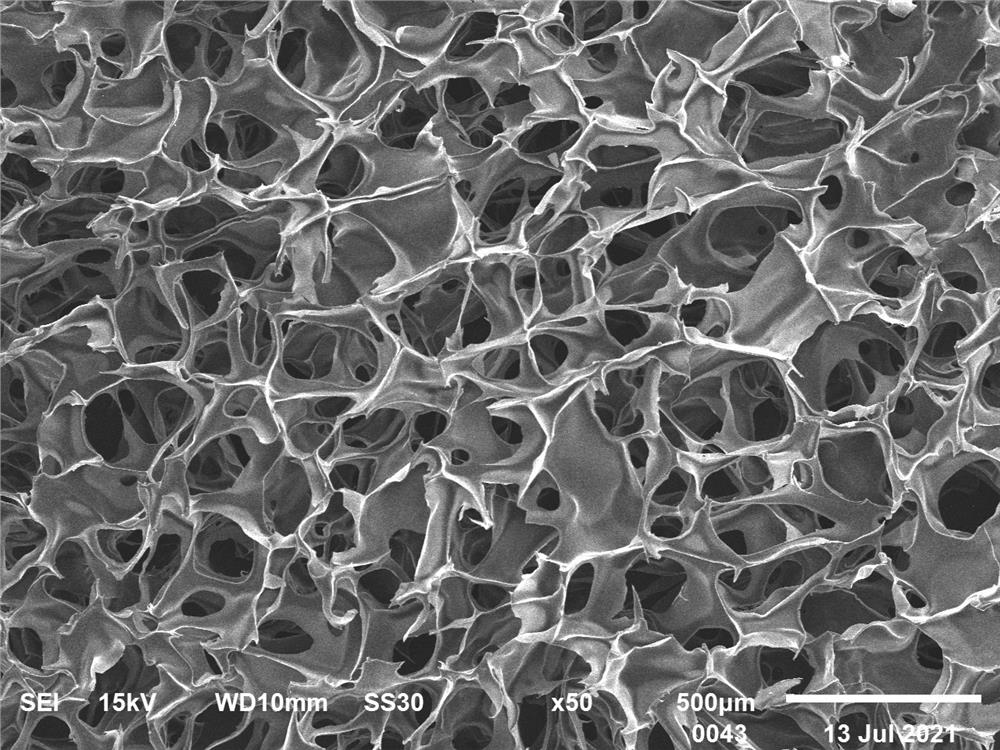

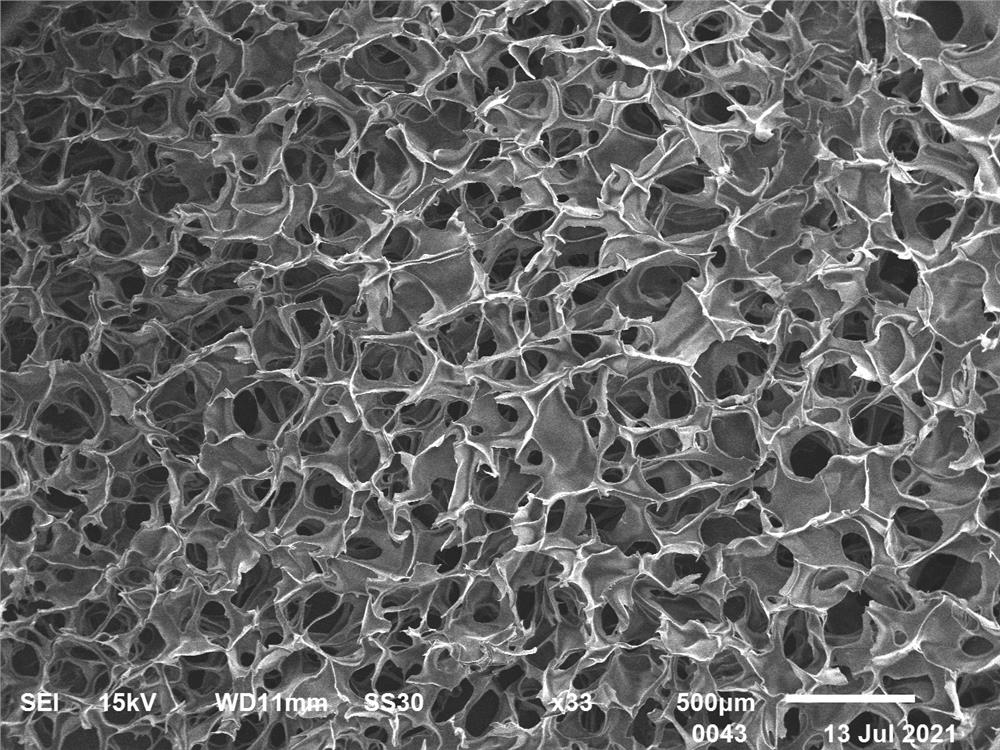

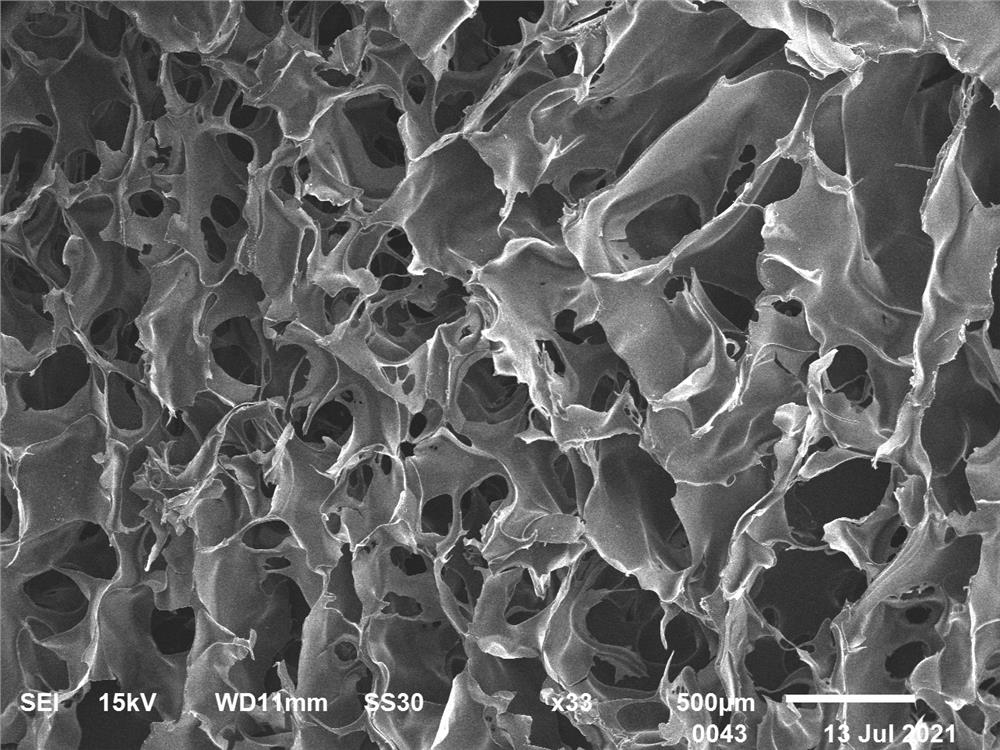

Image

Examples

Embodiment 1

[0043] The method of preparing a medical sponge according to the present embodiment includes the steps of:

[0044] (1) Construction of a rigid structure: in an environment at 60 ℃, 4g of hydroxypropyl cellulose (2% viscosity: 15000mPa.s, 20 ℃) material was added 96g of purified water, stir to dissolve, gel-like, to give hydroxypropyl cellulose hydrogel slurry and the resulting slurry hydroxypropylcellulose hydrogels using 0.5mol / L hydrochloric acid solution was adjusted to pH 2, and then the formaldehyde solution was added 0.1g, mixed thoroughly and allowed to stand 60 ℃ set 4h, to give a 2% viscosity (20 ℃) crosslinked hydroxypropyl cellulose hydrogel slurry of 210000mPa.s.

[0045] (2) Construction of the flexible structure: in an environment at 60 ℃, 4g of sodium carboxymethylcellulose (degree of substitution of 0.5, 2% viscosity: 3500mPa.s, 20 ℃) was added uniformly dispersed in 20g absolute ethanol, followed by addition of 0.05g glyoxal solution, after the crosslinki...

Embodiment 2

[0051] The method of preparing a medical sponge according to the present embodiment includes the steps of:

[0052] (1) Construction of a rigid structure: in a water bath at 40 ℃, 4g of hydroxypropylmethyl cellulose (2% viscosity: 60000mPa.s, 20 ℃) material was added 96g of purified water, stir to dissolve, gel-like to give hydroxypropylmethylcellulose hydrogel slurry and the resulting slurry hydroxypropylmethylcellulose hydrogel using 1mol / L acetic acid pH adjusted to 5 and then added 0.001g glutaraldehyde solution, sufficiently mix well and allowed to stand for 40 ℃ 4h, to give a 2% viscosity (20 ℃) hydroxypropylmethyl cellulose crosslinked hydrogel slurry of 300000mPa.s.

[0053] (2) Graft drugs: 5g of powder was dissolved hydrocortisone from step (1) hydroxypropylmethyl cellulose crosslinked hydrogel slurry was prepared, mixed well and allowed to stand for 2h at 40 ℃.

[0054] (3) Construction of the flexible structure: in a water bath at 40 ℃, 4g of hydroxyethyl cellulo...

Embodiment 3

[0058] The method of preparing a medical sponge according to the present embodiment includes the steps of:

[0059] (1) Construction of a rigid structure: at room temperatures, a 0.8g sodium carboxymethyl cellulose (2% viscosity: 5000mPa.s, 20 ℃) was added 99.2g of purified water, stir to dissolve, gel-like, to give sodium carboxymethyl cellulose hydrogel slurry and the resulting slurry-hydrogel 1mol / L of phosphoric acid to adjust the pH to 3, followed by addition of 0.001g epichlorohydrin solution, mixed thoroughly and allowed to stand at room temperature 4h, to give a 2% viscosity (20 ℃) crosslinked sodium carboxymethylcellulose hydrogel slurry of 120000mPa.s.

[0060] (2) Graft drugs: 5mg of mometasone furoate, dissolved in step (1) cross-linked sodium carboxymethylcellulose hydrogel slurry obtained thoroughly mixed and allowed to stand at room temperature 2h.

[0061] (3) Construction of the flexible structure: environment at room temperature, 4g of hydroxyethyl cellulos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com