A kind of non-burning and non-steaming foam insulation composite material and preparation method thereof

A composite material and foam technology is applied in the field of non-burning and non-steaming foam thermal insulation composite materials and its preparation, which can solve the problems of high thermal conductivity and energy consumption, and achieve the effects of improving thermal insulation performance, promoting hardening and promoting adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

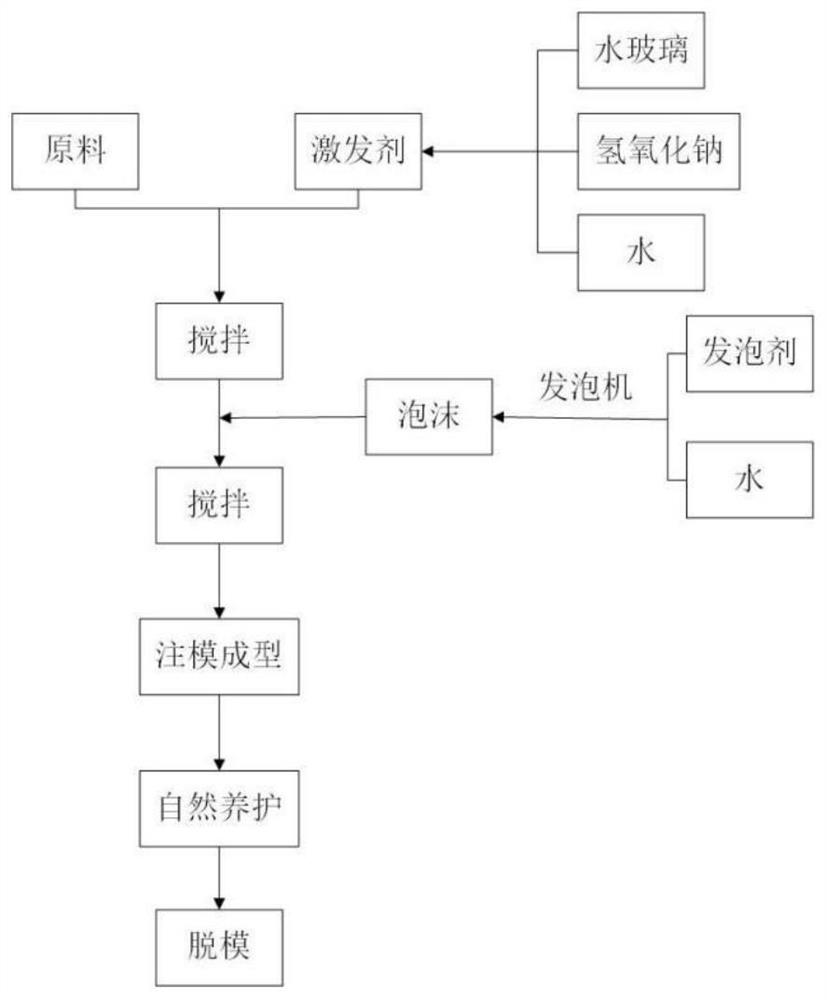

[0043] The present invention also provides the preparation method of the non-burning and non-steaming foam thermal insulation composite material according to the above technical solution, comprising the following steps:

[0044] The raw materials are mixed to obtain a mixed material;

[0045] The mixed material is poured into a mold for curing to obtain a non-burning and non-steaming foam thermal insulation composite material.

[0046] In the present invention, each raw material is mixed to obtain a mixed material.

[0047] In the present invention, the mixing of described raw materials preferably includes the following steps:

[0048] (1) mixing waste porcelain powder, red mud, cement, early strength agent, desulfurization gypsum, water reducing agent, foam stabilizer, water and activator to obtain a mixture after activation;

[0049] (2) mixing the excited mixture obtained in the step (1) with a foamed foaming agent to obtain a mixture.

[0050] In the present invention, ...

Embodiment 1

[0063] Raw materials (mass percentage): waste porcelain powder 55%, red mud 5%, cement 40%;

[0064] Based on the total mass of waste porcelain powder, red mud and cement, early strength agent 4%, desulfurization gypsum 7%, polycarboxylate water reducing agent 0.5%, calcium stearate 8%, activator 14%, animal protein foaming agent 0.39%, water 60%.

[0065] making process:

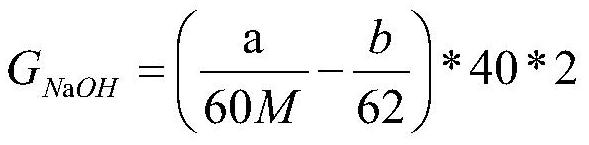

[0066] (1) The waste porcelain powder and the red mud are ground and passed through a 20-mesh sieve, for subsequent use; water glass, sodium hydroxide and water are mixed to obtain an activator; wherein, the modulus of the water glass is 2, and the water glass in the activator The mass ratio to water is 0.14:0.6, and the mass content of sodium hydroxide in the activator is 11%.

[0067] (2) Put the above-mentioned activator together with waste porcelain powder, red mud, cement, early strength agent, desulfurized gypsum, polycarboxylate water reducing agent, calcium stearate and water in a JJ-5 planetary m...

Embodiment 2

[0072] Raw materials (mass percentage): waste porcelain powder 50%, red mud 10%, cement 40%;

[0073] Based on the total mass of waste porcelain powder, red mud and cement, early strength agent 4%, desulfurization gypsum 7%, polycarboxylate water reducing agent 0.5%, calcium stearate 8%, activator 14%, animal protein foaming agent 0.39%, water 60%.

[0074] making process:

[0075] (1) The waste porcelain powder and the red mud are ground and passed through a 20-mesh sieve, for subsequent use; water glass, sodium hydroxide and water are mixed to obtain an activator; wherein, the modulus of the water glass is 2, and the water glass in the activator The mass ratio to water is 0.14:0.6, and the mass content of sodium hydroxide in the activator is 11%.

[0076] (2) Put the above-mentioned activator and waste porcelain powder, red mud, cement, early strength agent, desulfurized gypsum, polycarboxylate water reducer, calcium stearate and water in a JJ-5 planetary mixer, and accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com