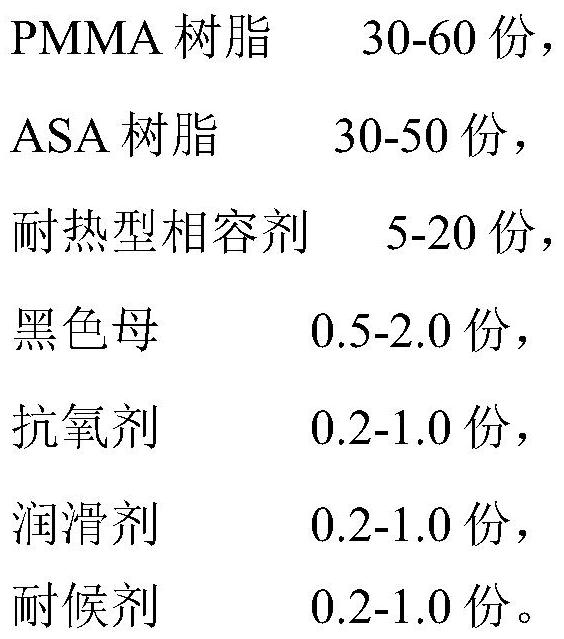

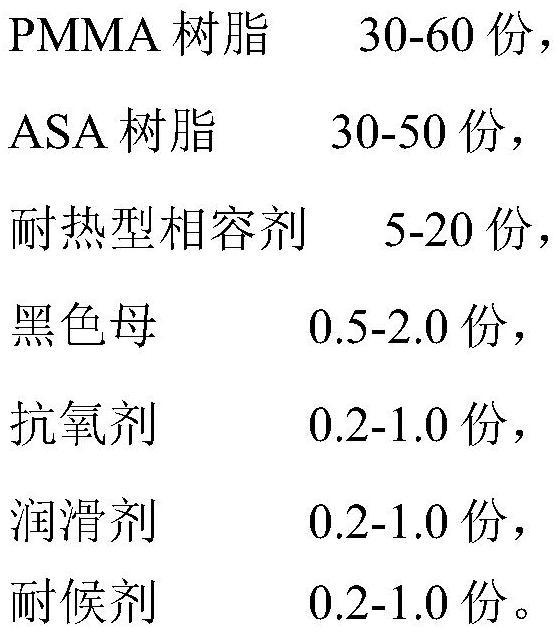

Spraying-free PMMA/ASA alloy resin composition with high thermal-oxidative stability and high heat resistance and preparation method thereof

An alloy resin and composition technology, applied in the field of polymer material modification, can solve the problems of poor compatibility between PMMA and ASA, the high heat resistance requirements of products are not mentioned, and the comprehensive mechanical properties are difficult to meet, etc. Application prospect and industrial value, high surface gloss, effect of improving heat-resistant temperature and thermo-oxidative stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

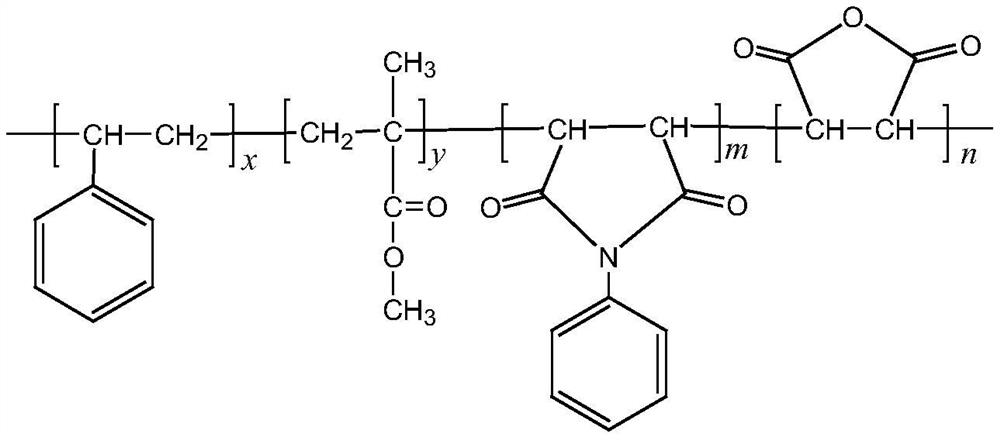

Method used

Image

Examples

Embodiment 1

[0038] 55 parts of PMMA resin (brand: CM211, Chi Mei Company), 40 parts of ASA resin (brand: XC500, Kumho Petrochemical Company), and the heat-resistant compatibilizer is styrene-methyl methacrylate-N-phenylmaline 5 parts of tetrapolymers of imide-maleic anhydride (wherein the content of maleic anhydride is 7%, the content of N-phenylmaleimide is 15%, and the content of methyl methacrylate is 18%) , 2 parts of black masterbatch (EMI-100 of Jiayi Rong Polymer (Shanghai) Co., Ltd. as carrier, relative molecular mass is 40000, residual acrylonitrile is 3ppm, carbon black filling is 60%), antioxidant (168 / 1010) 0.3 parts, lubricant (silicone) 0.4 parts, weather resistance agent is 0.5 parts of 2-hydroxy-4 methoxybenzophenone, after mixing the above raw materials evenly, put them into the In the extruder, the processing temperature is 200-240°C, and the rotation speed is 400 rpm. The samples are obtained through extrusion and granulation. After the particles are dried, they are in...

Embodiment 2

[0040] 60 parts of PMMA resin (brand: CM205, Chi Mei Company), 30 parts of ASA resin (brand: 600N, Japanese UMG company), and the heat-resistant compatibilizer is the ternary copolymerization of styrene-methyl methacrylate-maleic anhydride (the content of maleic anhydride is 18%, the content of methyl methacrylate is 20%, brand: BP-356M, Jiayi Rong Polymer (Shanghai) Co., Ltd.) 15 parts, black masterbatch (relative molecular mass is 70000 SAN resin is as carrier, and acrylonitrile residue is 12ppm, and carbon black filling is 40%) 1.2 parts, antioxidant (168 / 1076) 1.0 part, lubricant (PETS) 1.0 part, weather resistance agent is phenyl salicylate 0.2 parts, after mixing the above raw materials evenly, put them into an extruder with an aspect ratio of 56:1, the processing temperature is 180-230°C, the speed is 600 rpm, the sample is obtained by extrusion granulation, the particles are dried and then injected into a specific spline for testing.

Embodiment 3

[0042] 30 parts of PMMA resin (brand: MF001, Mitsubishi Rayon Company), 50 parts of ASA resin (brand: 776S, Korean Styrolution Company), and the heat-resistant compatibilizer is styrene-methyl methacrylate-maleic anhydride Terpolymer (12% of maleic anhydride and 25% of methyl methacrylate) and quaternary of styrene-methyl methacrylate-N-phenylmaleimide-maleic anhydride Copolymer (wherein the content of maleic anhydride is 13%, the content of N-phenylmaleimide is 18%, the content of methyl methacrylate is 15%), the terpolymer and tetrapolymer The mixture is 20 parts, wherein the proportion of the terpolymer is 30%, that is, the usage amount of the terpolymer and the tetrapolymer are respectively 6 parts and 14 parts. Acrylonitrile residue is 5ppm, carbon black filling is 50%) 0.5 part, antioxidant 0.4 part, lubricant 0.3 part, weather resistance agent is 2-(2'-hydroxyl-3', 5'-di-tert-butyl ) 1.0 parts of benzotriazole, after mixing the above raw materials evenly, put them into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com