Saccharomyces cerevisiae with low fusel yield and high ester yield and application of saccharomyces cerevisiae in fermented food production

A technology of Saccharomyces cerevisiae and fermented products, applied in the direction of beer fermentation methods, applications, food ingredients, etc., can solve the problems of high alcohol content, low fusel alcohol, low content, etc., and achieve the effect of good temperature tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1, screening and identification of Saccharomyces cerevisiae strains

[0071] (1) Sample preparation and strain isolation

[0072] The rice wine fermentation broth from the traditional handmade rice wine brewing process in Shaoxing area was collected and stored at 4°C, and 1 mL of the mixed sample was taken, and serially diluted with sterile water (10 -1 -10 -5 ), take 100 μL of the diluted sample, spread it on a YPD plate, invert the coated plate, and culture it at 28°C for 48 hours. Strains in the physiological form of yeast are purified by streaking multiple times, and finally the obtained pure strains are numbered and preserved.

[0073] (2) Strain identification

[0074] The morphological characteristics of the strain are sequenced by ITS, and the ITS sequence of Saccharomyces cerevisiae jiangnan2# is shown in SEQ ID NO.1. The homology between the strain and Saccharomyces cerevisiae is more than 99% according to the comparison and analysis in the NCBI...

Embodiment 2

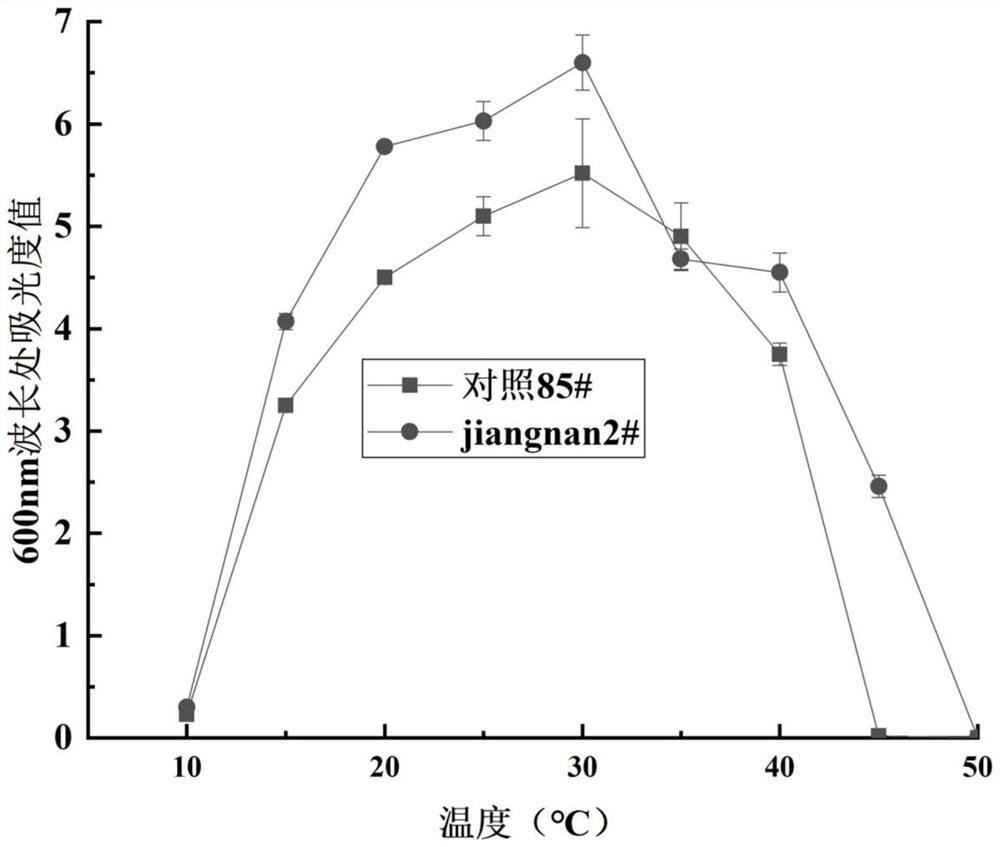

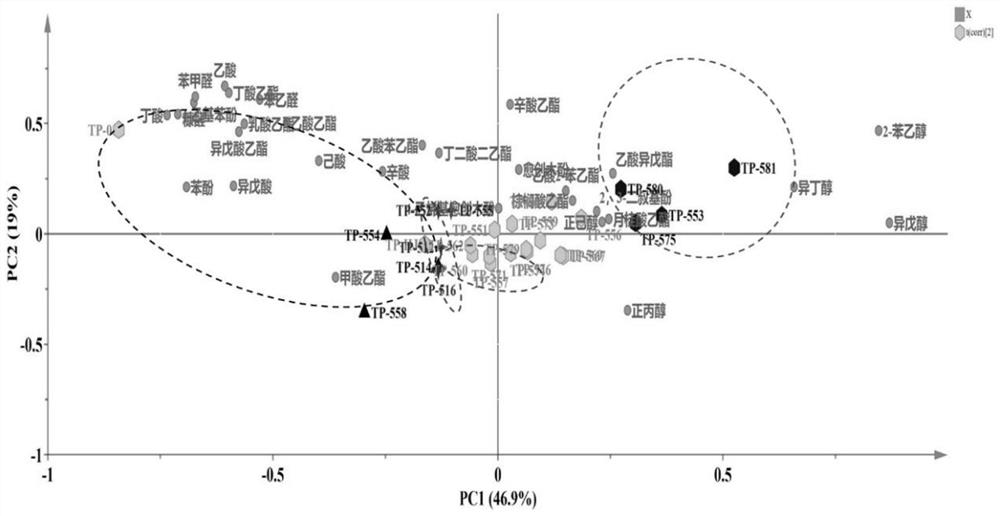

[0075] Embodiment 2, the breeding of low-yielding fusel alcohol high-yielding Saccharomyces cerevisiae (S.cerevisiae) bacterial strain jiangnan2#

[0076] 1. Preliminary screening of rice wine fermentation based on Saccharomyces cerevisiae isolates: In order to select Saccharomyces cerevisiae with excellent fermentation performance that can meet the needs of rice wine brewing, all the isolates were made into instant brewer's yeast and then fermented rice wine. After the fermentation, the physical and chemical indicators such as alcohol content were measured According to different batches, the fusel alcohols and flavor substances whose alcohol content meets the national standard are screened. Specific steps are as follows:

[0077] (1) Raw material ratio of traditional rice wine fermentation selected in the present embodiment

[0078] Based on glutinous rice 100%, the raw materials include 125% water, 12%-15% wheat koji, and 10%-15% instant distiller's mother. Specific to the...

Embodiment 3

[0102] The preparation of embodiment 3 low-yield fusel alcohol high-yield ester Saccharomyces cerevisiae jiangnan2# starter

[0103] (1) Taking instant distiller's mother as an example, the instant distiller's mother containing S. cerevisiae jiangnan2# was prepared for brewing rice wine.

[0104] The production method of instant brewer's yeast is as follows: Saccharomyces cerevisiae strains stored in glycerol tubes are prepared on a slant, and the Saccharomyces cerevisiae jiangnan2# strain screened in Example 1 cultivated on the slant is inoculated in the rice saccharification liquid medium, and the culture temperature is 28 °C ± 2 °C Shake culture under the condition of 24h, obtain first-class seed liquid (bacterial liquid concentration 10 6 -10 8 CFU / mL), inoculate the first-level seed liquid into the new rice saccharification liquid medium at a ratio of 5%-10%, shake and cultivate for 36h-48h at a culture temperature of 28°C±2°C to obtain the second-level seed liquid , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com