Composite solid propellant based on multi-scale modified nitramine oxidant and preparation method

A technology of solid propellant and oxidant, which is applied in the direction of offensive equipment, compressed gas generation, explosives, etc. It can solve the problems of sudden increase in high-pressure burning rate, inaccurate catalysis of burning rate catalyst, and low combustion efficiency of solid propellant. Contradictory problems, the effect of increasing production and use safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation process of the embodiment can be divided into the following four steps:

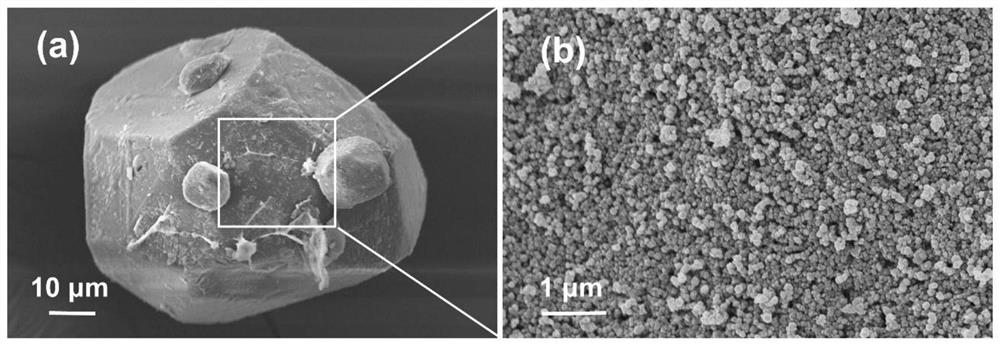

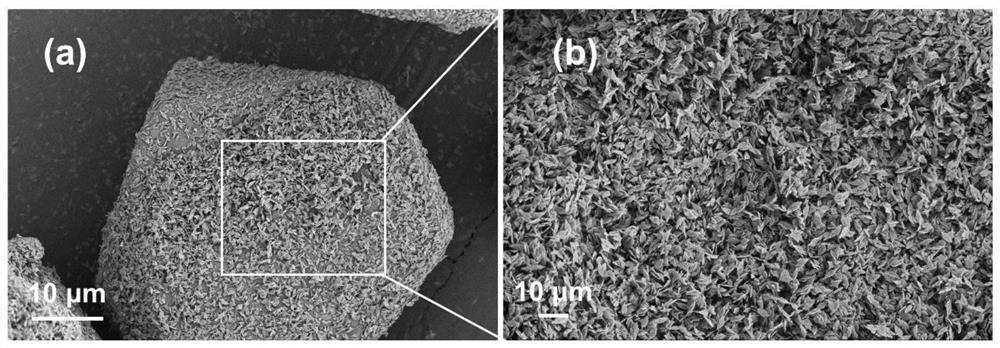

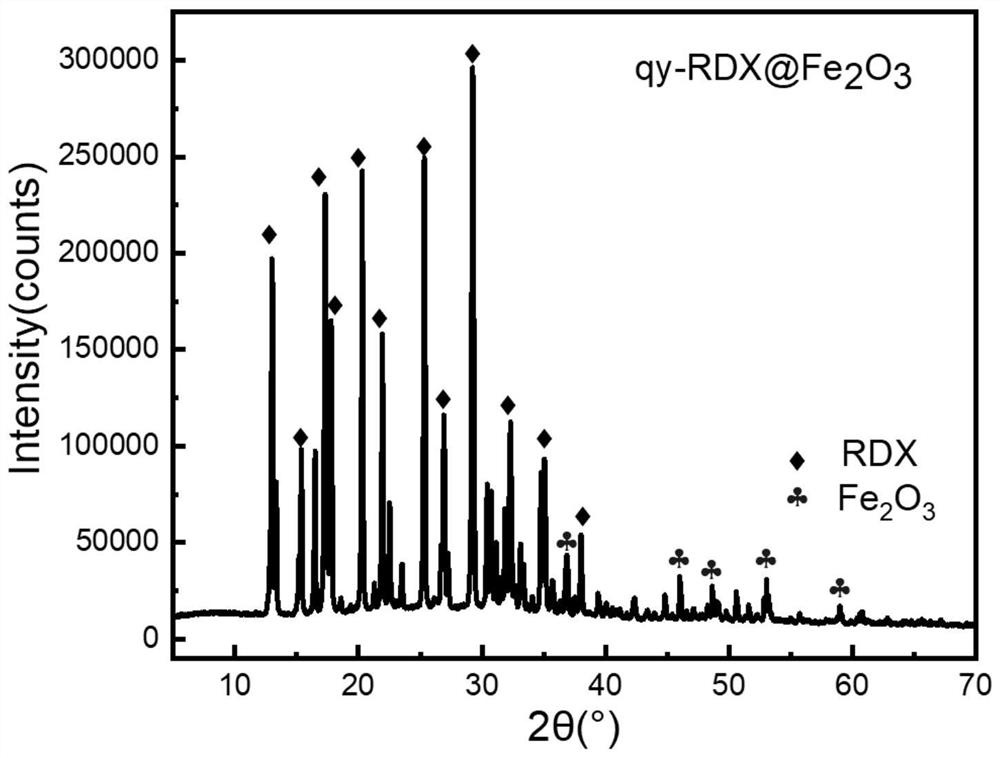

[0044] (1) Preparation of passivated modified nitramine crystals: Dissolve triaminoguanidine hydrochloride TAG (2.5mmol, 119.2mg) in dimethyl sulfoxide (DMSO, 7.3mL), and heat to Stir at 100°C for 30min, then add nitramine (RDX / HMX / CL-20, 5mmol) to the solution, stir for 30min, the solution gradually changes from colorless and transparent to pink. The above solution was kept in an oil bath at a temperature of 105° C., and then 2.5 mmol (290.2 μL) of glyoxal aqueous solution was added. The 2D flexible TAGP material can be produced after 1 hour of cross-linking reaction. Finally, at 1.008mL·min -1 The flow rate of the antisolvent (H 2 O). DMSO and anti-solvent H 2 The volume ratio of O was kept at 1:2. Finally, the precipitated crystals were filtered out and washed with distilled water to obtain passivated modified nitramine crystals.

[0045] (2) Preparation of dopamine-coate...

example 1

[0050] Example 1: A composite solid propellant without a burn rate catalyst. The ammonium perchlorate (AP) content is 57wt%, the μ-Al content is 18wt%, and the RDX content is 10wt%. The binder adopts hydroxyl-terminated polybutadiene (HTPB, 11.5wt%), and the plasticizer adopts sunflower Acid diisooctyl ester (DOS, 2.5wt%), curing agent adopts isophorone diisocyanate (IPDI, 1wt%). The propellant preparation method is as follows:

[0051] (a) Drying treatment of raw materials: dry the solid material in an oven at 60°C for 96 hours;

[0052] (b) Propellant components are fully mixed: Weigh a certain mass of propellant components according to the formula, and add AP, HTPB, DOS, IPDI, RDX, and micron aluminum powder into the mixer in sequence, and place them in a water bath at 60°C Stir to make it evenly mixed;

[0053] (c) Vacuum pouring: pour the propellant slurry into the customized mold, and the vacuuming time is greater than 12h;

[0054] (d) Curing: heat and cure the vacu...

example 2

[0056] Example 2: The propellant formula and preparation steps are the same as Example 1, only the RDX in Example 1 is replaced by inactivated modified qy-RDX;

[0057] qy-RDX is more insensitive than RDX, and no cracks are produced under the action of electron beam ( Figure 9 ). The melting endothermic peak of Example 2 is slightly lower than that of Example 1, which is 204.2°C, but the endothermic heat is reduced; compared with Example 1, the peak temperature of the exothermic peak of AP in Example 2 is reduced by 5.6°C, and the heat of decomposition is increased to 1011.0 J·g -1 , the thermal weight loss of the example 2 propellant in the uncontrollable reaction zone increases by 4.42%, and the thermal decomposition remaining mass decreases by 4.52% ( Figure 10 ). The burning rate of the propellant in Example 2 increased to 3.37mm·s at 0.5MPa -1 , the burning rate pressure exponent n is 0.314( Figure 11). qy-RDX can only improve its own reactivity and slightly incr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat release | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com