A method for growing aluminum nitride single crystal by physical vapor transport method

A technology of physical vapor transport and aluminum nitride, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of low growth rate and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, a high-quality aluminum nitride single crystal is grown by using the physical vapor transport method of the present invention, as follows.

[0035] Step 1: Fix the high-purity aluminum nitride raw material around the inner wall of the crucible.

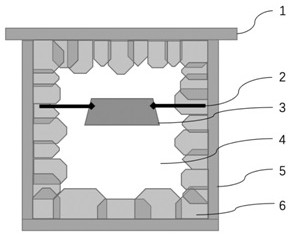

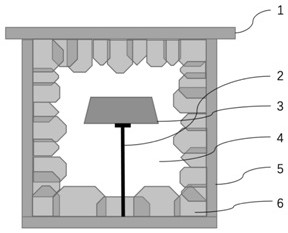

[0036] as attached Figure 1-3 It is a schematic diagram of fixing the aluminum nitride raw material on the inner wall of the crucible and fixing the seed crystal in this embodiment. As shown in the figure, in this embodiment, the crucible is composed of a crucible body and a crucible cover to form a closed chamber, wherein the crucible is made of high temperature resistant tungsten by the crucible body and the crucible cover, and the material of the crucible is not limited to tungsten , Using other high temperature resistant materials such as tantalum, tantalum carbide, tungsten carbide, graphite, boron nitride, etc. can achieve the purpose of the present invention. The AlN raw materials in this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com