Novel compounding method of carbon material and transition metal compound, composite material and application

A technology of transition metals and composite materials, applied in the field of material composites, can solve the problems of reducing the contact area between nanoparticles and electrolyte, increasing the difficulty and complexity of the process, and affecting the catalytic reaction activity, etc., to achieve multi-interface active sites, high Pseudocapacitance effect contribution rate, the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The novel composite method of the carbon material and the transition metal compound comprises the following steps:

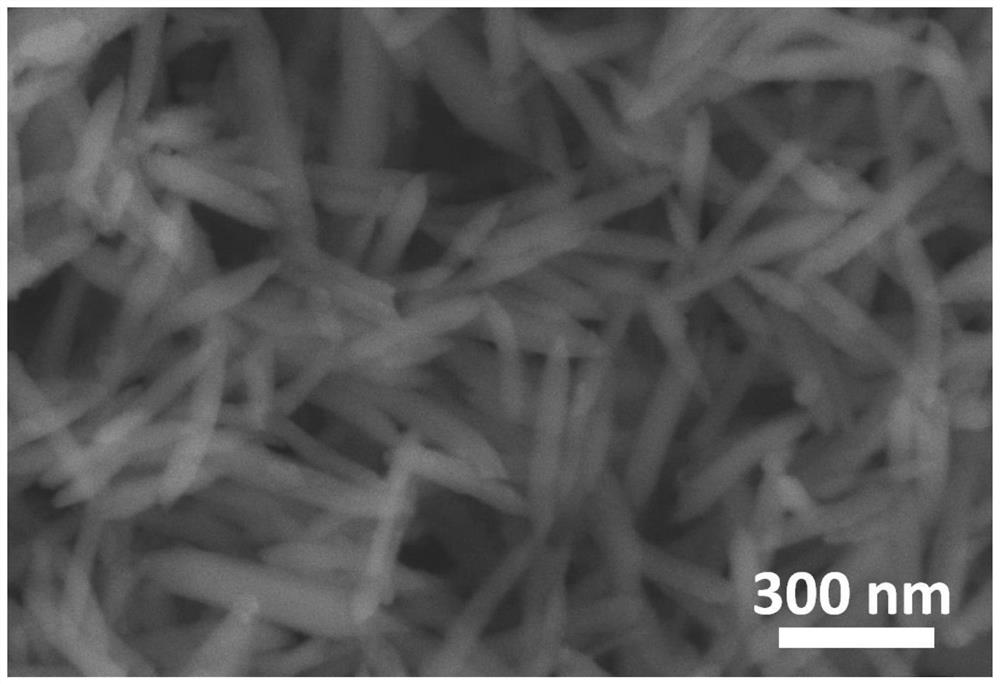

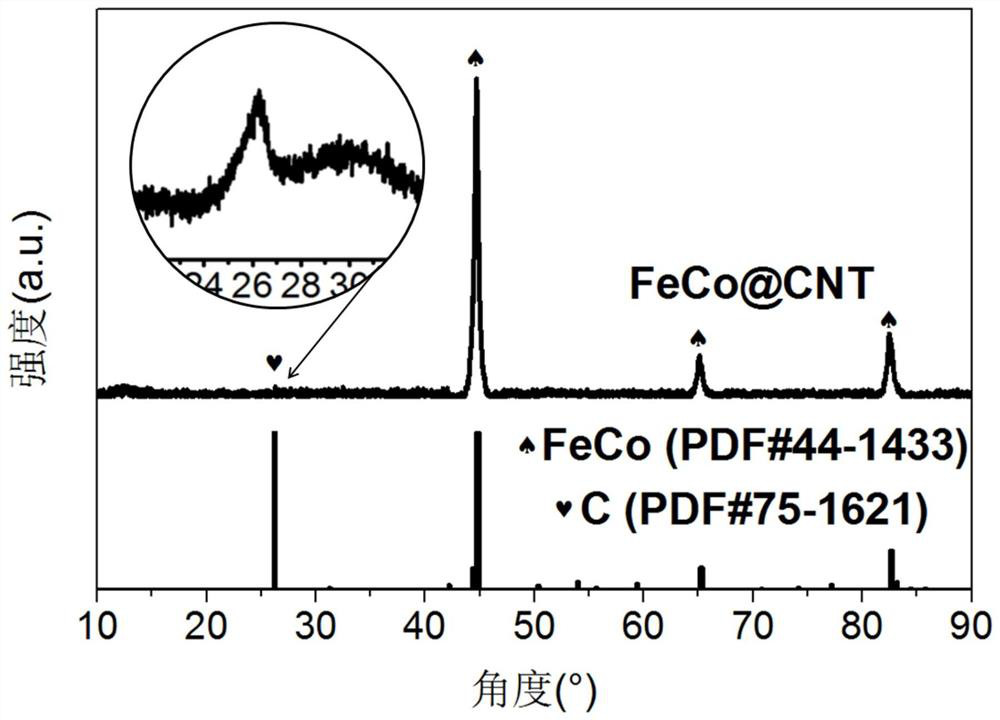

[0039] (1) Synthesis of iron-cobalt MOF precursor: First, mix 15mL ethanol with 25mL N,N-dimethylformamide solution to prepare solution A; mix 70.6mg iron acetylacetonate, 49.8mg cobalt acetate tetrahydrate and 200mg polyvinylpyrrolidone (Mw=40000) was mixed and dissolved in the obtained solution A and ultrasonically treated for 10 min to obtain a solution B; 25 mg of terephthalic acid was added to the obtained solution B, and the magnetic stirring was continued for 10 min to obtain a mixed solution after being ultrasonically dissolved at room temperature; The resulting mixed solution was transferred to a 100mL hydrothermal reaction kettle, kept in a blast oven at 100°C for hydrothermal reaction for 5h, and cooled to room temperature naturally after the reaction was completed, then the product was washed three times by centrifugation with water and ethanol...

Embodiment 2

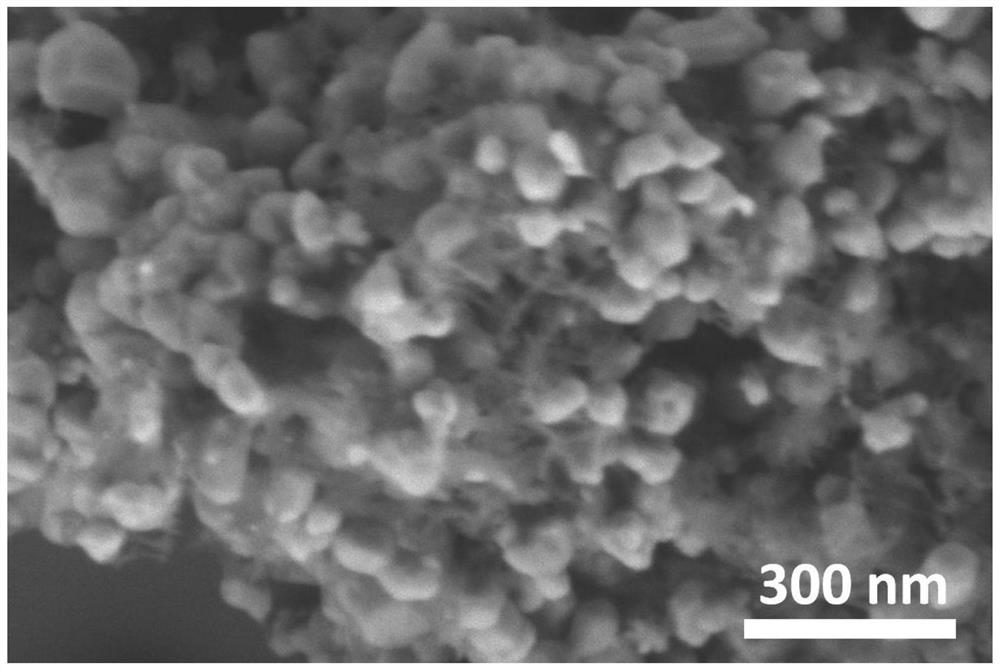

[0043] Repeat the steps of Example 1 to adjust the polyvinylpyrrolidone in S2 to polyvinylpyrrolidone with a molecular weight of 10000.

Embodiment 3

[0045] Repeat the steps of Example 1, and adjust the polyvinylpyrrolidone in S2 to polyvinylpyrrolidone with a molecular weight of 1,300,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com