Preparation method and use method of Maillard flavor enhanced peptide product

A technology for flavor enhancement and peptide products, which is applied in the field of preparation of Maillard flavor enhancement peptide products, can solve the problems of weak aroma, high reaction temperature, sticky state, etc., achieve rich natural flavor and nutrition, reduce the temperature of the reaction system, Maintain the original color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

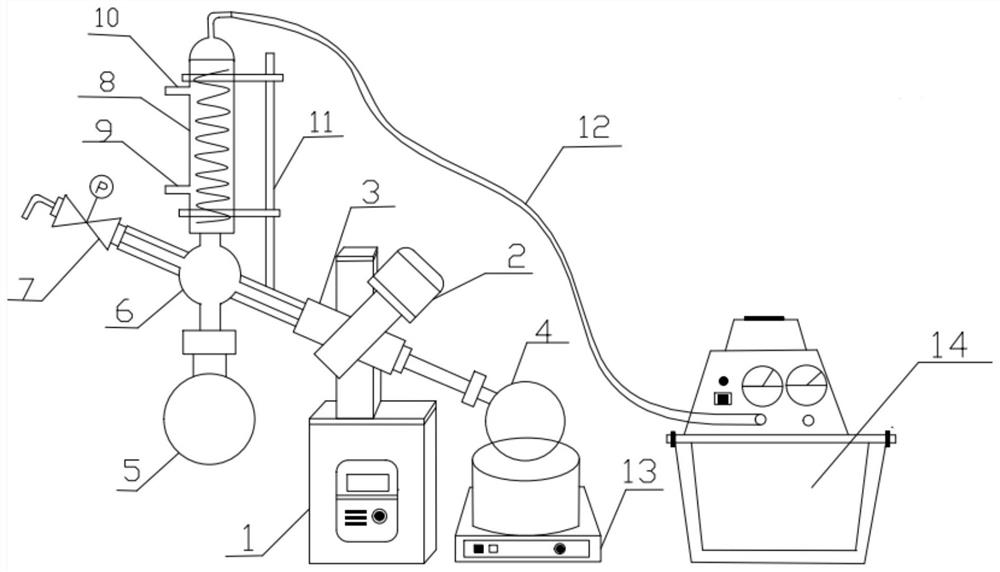

[0040] The invention provides a method for preparing a Maillard flavor enhancing peptide product, comprising the following steps:

[0041] 1. Preparation of enzymatic hydrolysis solution

[0042] Weigh the sesame meal / sesame cake, add water, and heat in a water bath at 80°C for 30 minutes. The process of adding water and heating is conducive to protein denaturation and enzymolysis, and can quickly form small molecular polypeptides and amino acid products; cool to room temperature, Adjust the pH to 9.5, the alkaline system is conducive to the dissolution of protein; add alkaline protease at a temperature of 50°C for 2 hours, and inactivate the enzyme at 90°C for 15 minutes; lower the temperature to room temperature and adjust the pH to 6.5, add papain, neutral Add protease and flavor protease at the same time, enzymolyze at 50°C for 3 hours, after the reaction is complete, heat to 90°C, inactivate the enzyme, place it at room temperature, centrifuge at 4°C, 12000r / min, and coll...

Embodiment 1

[0049] 1. Preparation of enzymatic hydrolysis solution

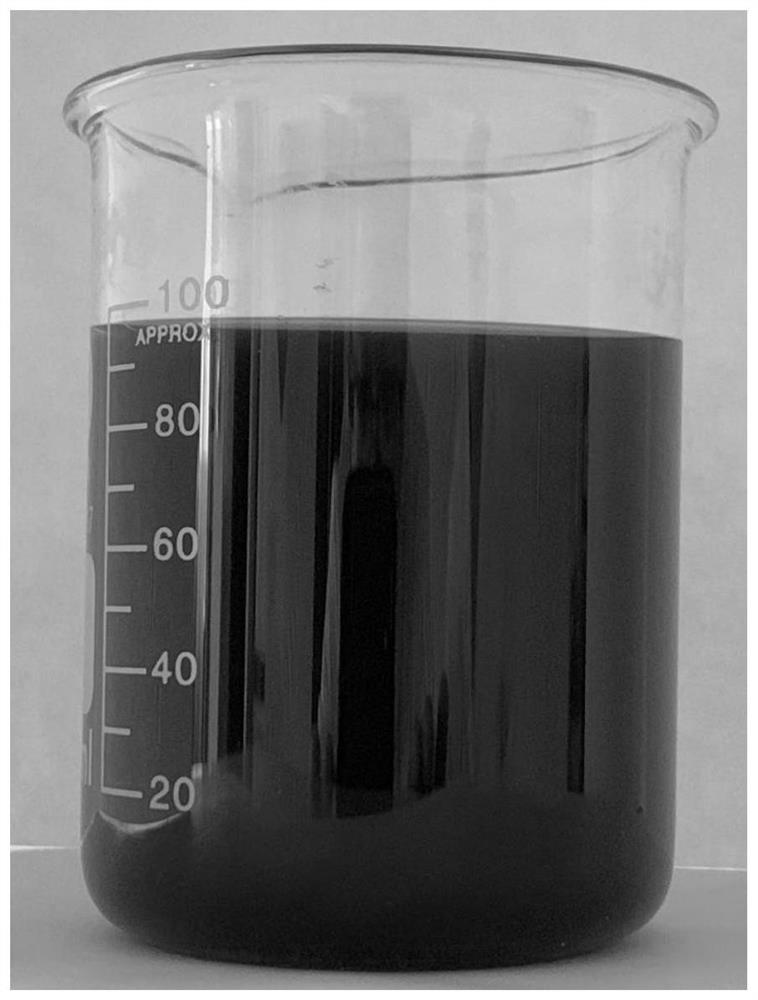

[0050] Weigh 50g of sesame meal (crushed into 100 mesh), add ten times the mass of water (500ml), heat in a water bath at 80°C for 30min, then cool to room temperature, adjust the pH to 9.5 with a pH meter, and the temperature is 50°C Add 0.875g of alkaline protease under the conditions of enzymatic hydrolysis for 2 hours, then inactivate the enzyme at 90°C for 15 minutes, lower the temperature to room temperature and adjust the pH to 6.5, add 0.0917g of papain, 1.25g of neutral protease, and 0.1g of flavor protease, and add them at the same time. Enzymolysis at 50°C for 3 hours, after the reaction is complete, heat to 90°C, inactivate the enzyme, place it at room temperature, and finally centrifuge in a high-speed refrigerated centrifuge at 4°C, 12000r / min to collect the water layer, namely For enzymatic hydrolysis solution (such as figure 1 shown), the enzymatic hydrolysis solution can be used for the subsequent Maill...

Embodiment 2

[0056] On the basis of Example 1, the parameters of the reaction were adjusted. The volume ratio of enzymolysis solution to sesame oil is 1:6, the mass volume ratio of xylose to enzymolysis solution is 1g:5ml, the mass volume ratio of cysteine to enzymolysis solution is 1g:5ml, and the vacuum is generally 50KPa. , first at 80°C, the volume of the water system is reduced by about 55%, increase the temperature to 100°C, evaporate all the water to dryness, then increase the temperature to 120°C, and react for 15-25min. Others are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com