Laminate

A laminated body and shape technology, applied in layered products, synthetic resin layered products, furniture parts, etc., can solve the problems of high specific gravity and high cost, and achieve the effect of excellent destructive compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

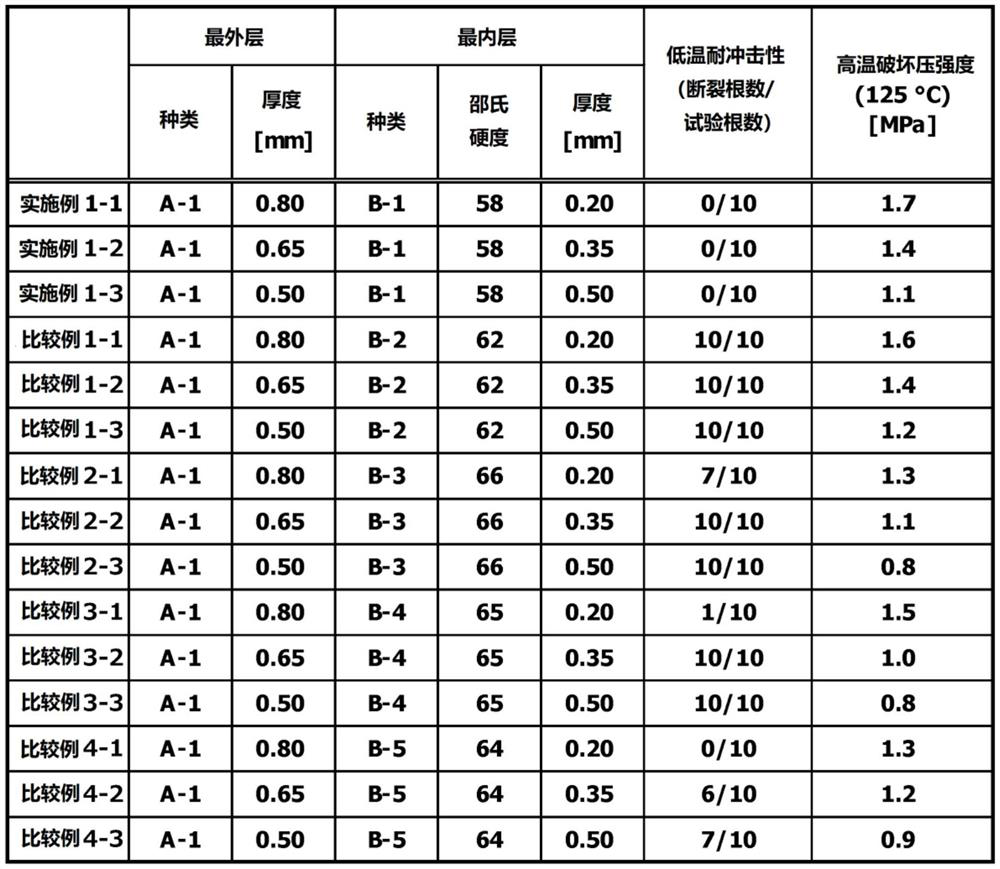

[0212] Using the aliphatic polyamide composition (A-1) and the modified polyolefin (B-1) shown above, using a PAL32 (manufactured by Mylfare Co., Ltd.) double-layer pipe forming machine, (A-1) was heated at 270° C. The extrusion temperature and (B-1) were respectively melted at an extrusion temperature of 220° C., and the discharged molten resins were merged by a confluencer to form a laminated tubular body. Then, it is cooled and removed by a sizing die for size control, and (a) layer (outermost layer) formed from (A-1) and (b) layer (outermost layer) formed from (B-1) are produced. In the case of the inner layer), a laminated tube having a layer configuration of (a) / (b)=0.80 / 0.20 mm, an inner diameter of 6.0 mm, and an outer diameter of 8.0 mm was obtained. Table 1 shows the measurement results of the physical properties of the laminated tubes (ie, the results of the high-temperature breaking compressive strength for 5 laminated tubes and the test results for the low-tempera...

Embodiment 1-2

[0214] In Example 1-1, except that the layer thickness was changed, by the same method as in Example 1-1, the layer composition (a) / (b)=0.65mm / 0.35mm and the inner diameter of 6.0mm were obtained. , A laminated tube with an outer diameter of 8.0 mm. Table 1 shows the measurement results of physical properties of the laminated tube.

Embodiment 1-3

[0216] In Example 1-1, except that the layer thickness was changed, the same method as in Example 1-1 was used to obtain a layer composition of (a) / (b)=0.50mm / 0.50mm and an inner diameter of 6.0mm , A laminated tube with an outer diameter of 8.0 mm. Table 1 shows the measurement results of physical properties of the laminated tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com