Hollow carbon sphere supported metal particle catalyst as well as preparation method and application thereof

A granular catalyst and hollow carbon sphere technology, applied in the field of catalysis, can solve the problems of active metal loss, catalyst deactivation, etc., and achieve the effects of small activity loss, improved selectivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

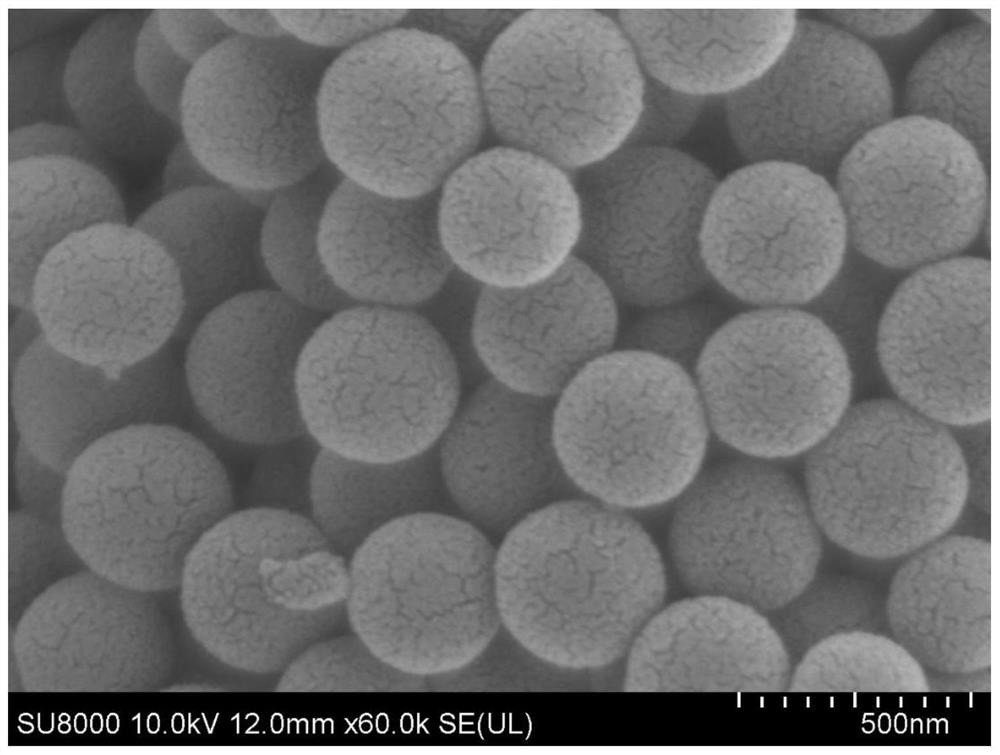

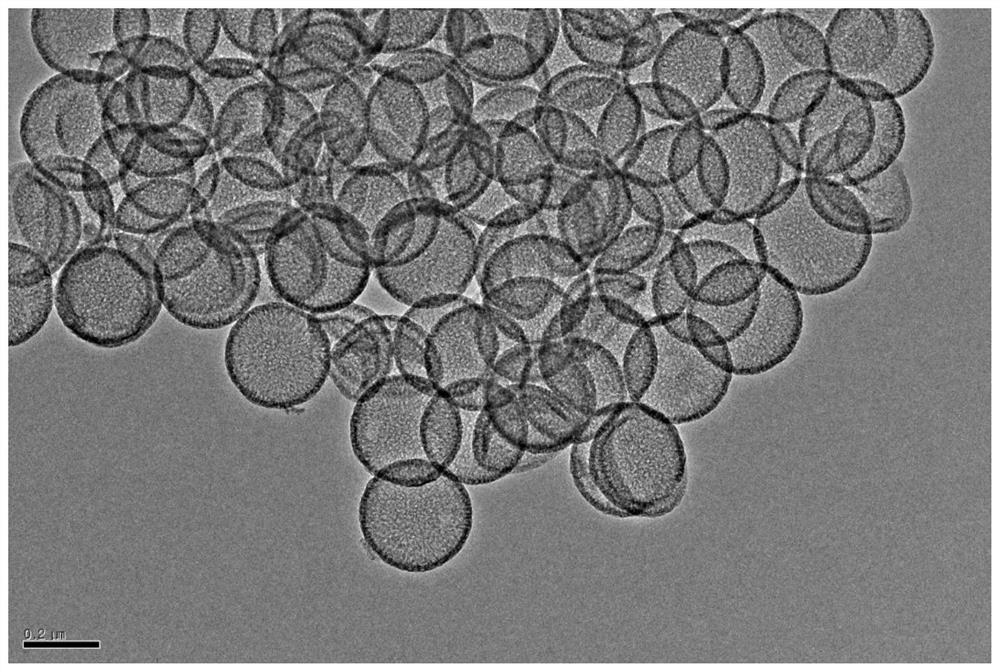

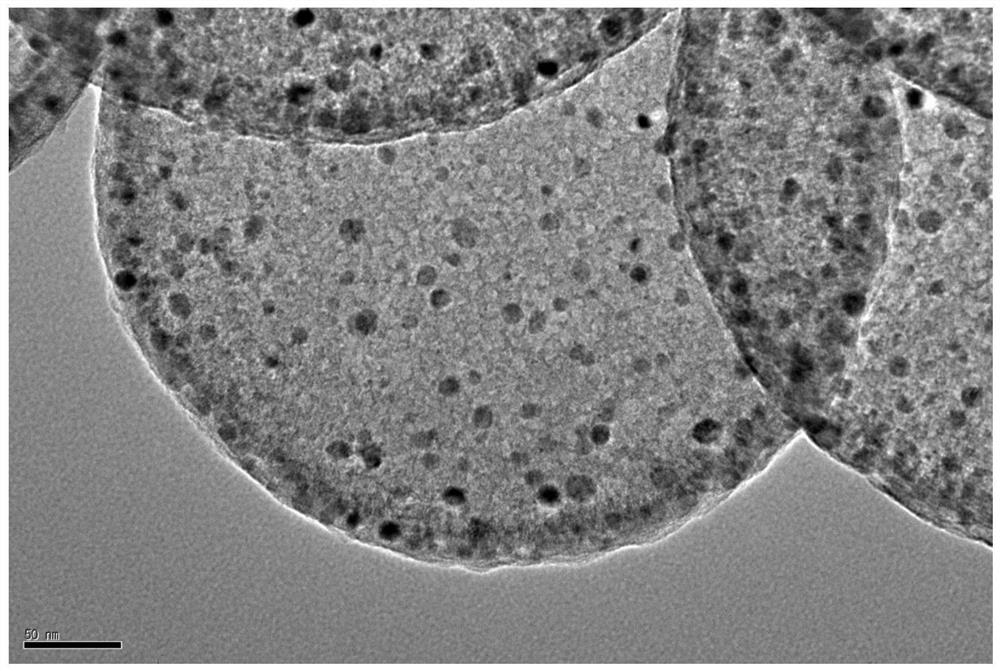

[0036] A highly stable hollow carbon-supported nickel-based catalyst is prepared by mixing hollow carbon and metal nickel at a mass ratio of 1:0.15. Wherein the preparation method of hollow carbon spheres and the loading method of metal nickel are as follows:

[0037] S1. Add 3ml of ammonia water to the mixed solution of 70ml of ethanol and 10ml of water. Then 3.56 ml of tetraethylsilicate was added quickly to the above solution under vigorous stirring. Stirring was continued until a white suspension was formed, then 0.4 g of resorcinol and 0.56 ml of formaldehyde aqueous solution were added thereto, and stirring was continued for 24 hours. The obtained khaki solid was centrifuged, washed with deionized water and absolute ethanol several times, and dried;

[0038] S2. The dried product is raised to 700°C at a rate of 2°C / min under a nitrogen atmosphere and kept for 5 hours to fully carbonize the phenolic resin on the surface.

[0039] S3. Then weigh 1 g of the carbonized so...

Embodiment 2

[0048] A highly stable hollow carbon-supported copper-based catalyst is prepared by mixing hollow carbon and metal copper at a mass ratio of 1:0.1. Wherein the preparation method of hollow carbon spheres and the loading method of metal copper are as follows:

[0049] S1. Add 3ml of ammonia water to the mixed solution of 70ml of ethanol and 10ml of water. Then 3.56 ml of tetraethylsilicate was added quickly to the above solution under vigorous stirring. Stirring was continued until a white suspension was formed, then 0.3 g of resorcinol and 0.56 ml of formaldehyde aqueous solution were added thereto, and stirring was continued for 24 hours. The obtained khaki solid was centrifuged, washed with deionized water and absolute ethanol several times, and dried;

[0050] S2. The dried product is raised to 700°C at a rate of 2°C / min under a nitrogen atmosphere and kept for 5 hours to fully carbonize the phenolic resin on the surface.

[0051] S3. Then weigh 1 g of the carbonized sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com