Catalyst for synthesizing 6-aminocapronitrile, preparation method thereof and method for synthesizing 6-aminocapronitrile by using catalyst

A technology of aminocapronitrile and catalyst, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of reduced service life, low selectivity, and low conversion rate, and achieve low requirements for preparation equipment, The effect of simple preparation method and long catalyst life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

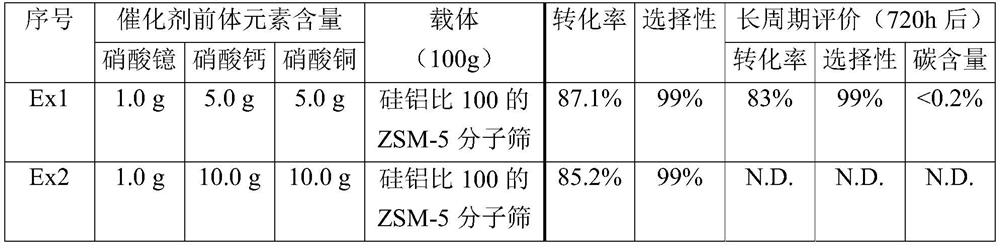

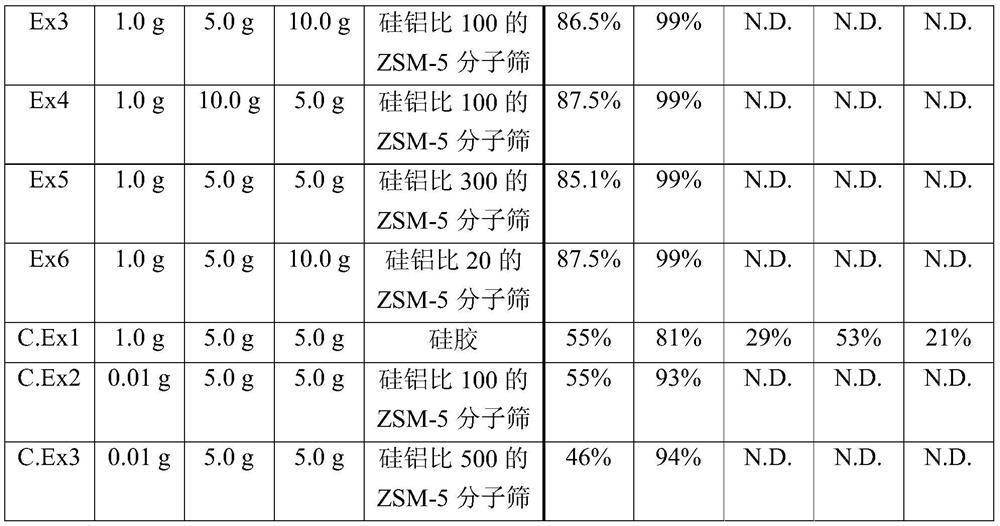

Embodiment 1

[0026] Catalyst preparation: Prepare a mixed aqueous solution of ternary active components: add accurately weighed 1.0g of ytterbium nitrate, 5.0g of calcium nitrate and 5.0g of copper nitrate to 300ml of desalted water, weigh 100g of ZSM-5 molecular sieve with a silicon-aluminum ratio of 100, and mix the molecular sieve The carrier was added to the mixed aqueous solution of the ternary active components, kept at 65°C and shaken for 6 hours, the excess water was evaporated under reduced pressure by a water pump, the residual solid was baked at 110°C for 4 hours, dried and molded, and calcined in a muffle furnace for 5 hours at 600°C to obtain the finished catalyst.

[0027] Catalyst performance evaluation: take 5g catalyst and fill it in a fixed bed reactor, preheater is filled with quartz sand, preheating temperature is 300°C, fixed bed layer is 300°C, mass space velocity of caprolactam is 6h -1 , the molar ratio of caprolactam to ammonia is 1:12. The molten caprolactam is fed...

Embodiment 2

[0030] Except that the amount of ytterbium nitrate, calcium nitrate and copper nitrate used in the preparation of ternary active component mixed aqueous solution is 1.0g ytterbium nitrate, except 10.0g calcium nitrate and 10.0g copper nitrate, prepare catalyst with the method identical with embodiment 1 .

[0031] The catalytic performance evaluation process of the catalyst was the same as in Example 1. As a result, the per-pass conversion of caprolactam was 85.2%, and the selectivity of 6-aminocapronitrile was 99%.

Embodiment 3

[0033] Except that the amount of ytterbium nitrate, calcium nitrate and copper nitrate used in the preparation of ternary active component mixed aqueous solution is 1.0g ytterbium nitrate, except 5.0g calcium nitrate and 10.0g copper nitrate, prepare catalyst with the method identical with embodiment 1 .

[0034] The catalytic performance evaluation process of the catalyst was the same as in Example 1. As a result, the per-pass conversion of caprolactam was 86.5%, and the selectivity of 6-aminocapronitrile was 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com