Moisture-proof and anti-aging PC carrier tape material and preparation method thereof

An anti-aging and carrier tape technology, which is applied in the field of packaging materials, can solve the problems of reduced mechanical properties of the carrier tape, unsatisfactory light-colored carrier tape, and light aging, so as to shorten the self-polymerization time, increase the anti-light aging gain, and improve compatibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

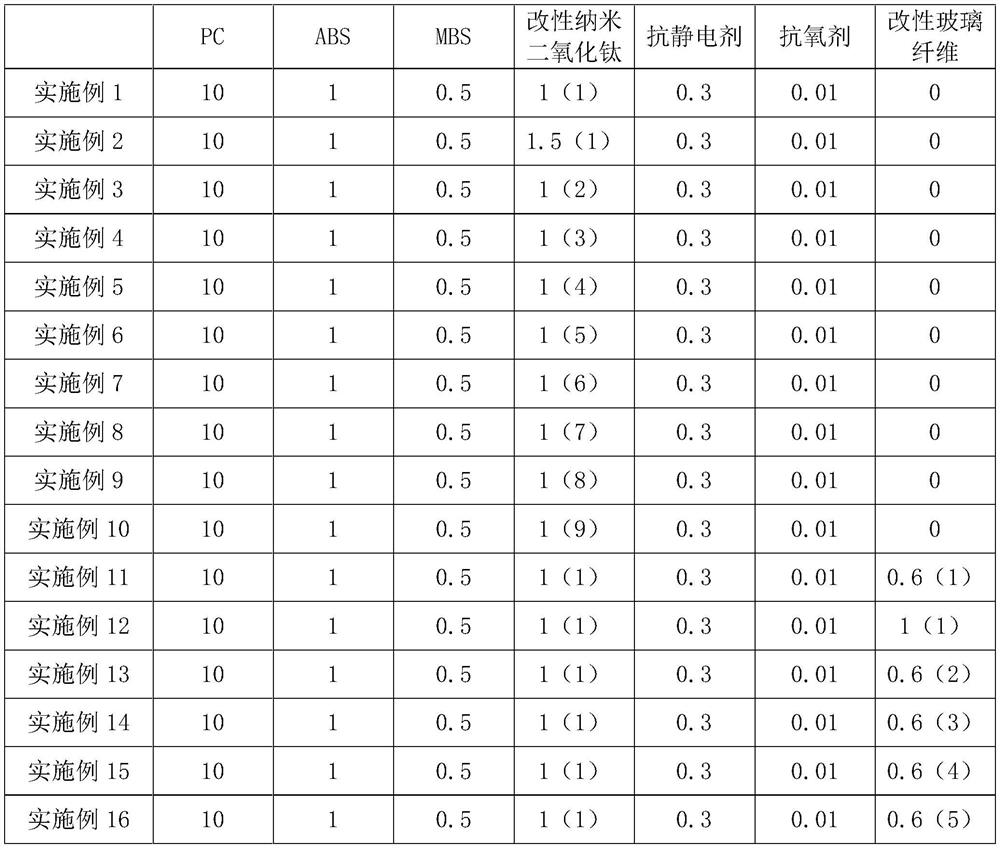

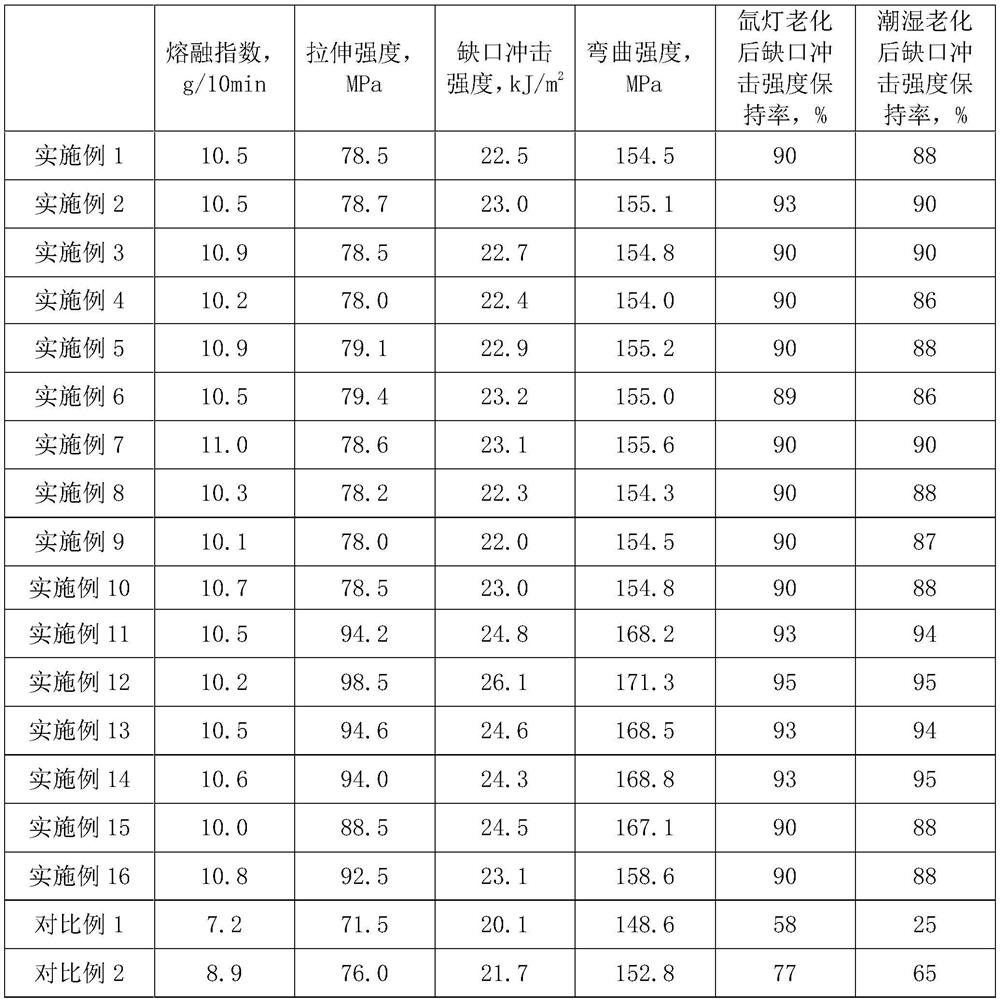

Examples

preparation example 1

[0052] Carboxylated cellulose is prepared as follows:

[0053] A, 20wt% hydrochloric acid, 10wt% citric acid aqueous solution and acetic anhydride are mixed according to the ratio of 10:10:2 by weight to obtain mixed acid solution;

[0054] B. Place 100g of microcrystalline cellulose in 100g of mixed acid solution, react for 6h at a temperature of 80°C, and filter to obtain a solid reaction product. Dry at a temperature of ℃ for 24 hours to obtain carboxylated cellulose.

preparation example 2

[0056] The difference between this preparation example and the preparation example 1 of carboxylated cellulose is that the mixed acid solution is composed of 25wt% hydrochloric acid, 15wt% citric acid aqueous solution and acetic anhydride in a weight ratio of 15:15:2.

preparation example 3

[0058] The difference between this preparation example and the preparation example 1 of carboxylated cellulose is that the mixed acid solution is composed of 20wt% hydrochloric acid, 10wt% citric acid aqueous solution and acetic anhydride in a weight ratio of 9:9:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com