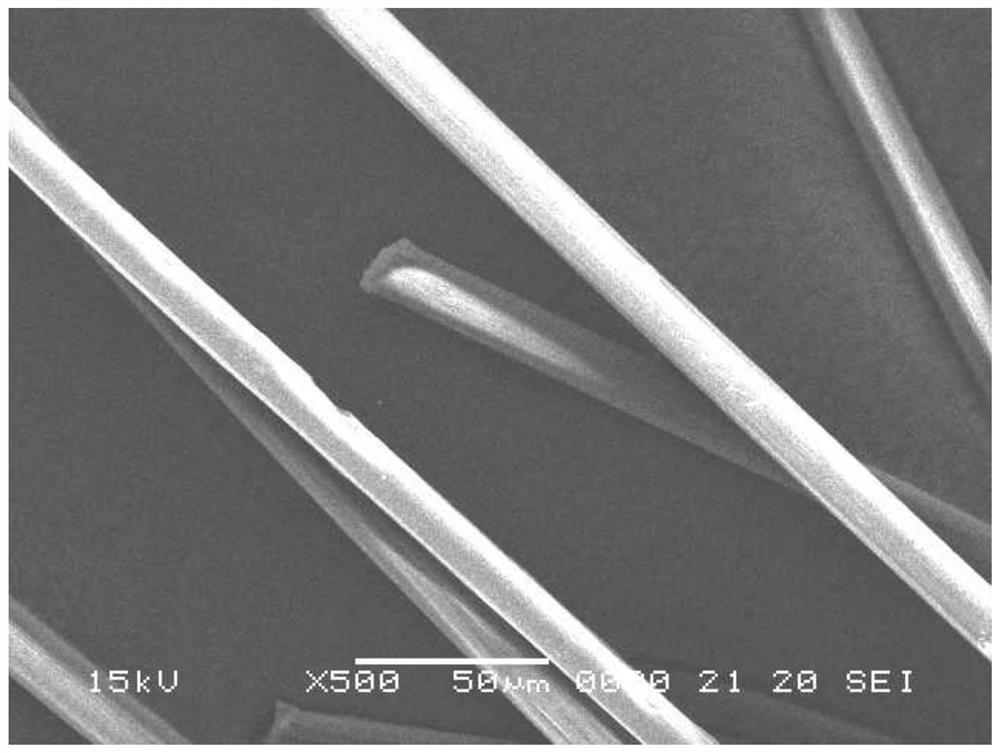

Smooth surface type meta-aramid filament and preparation method thereof

A smooth surface, aramid fiber technology, applied in the direction of filament/thread forming, rayon heat treatment, single-component polyamide rayon, etc. No obvious improvement, lack of surface smoothness, etc., to achieve the effect of improving spinning efficiency, improving product gloss and smoothness, and reducing the generation of wool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

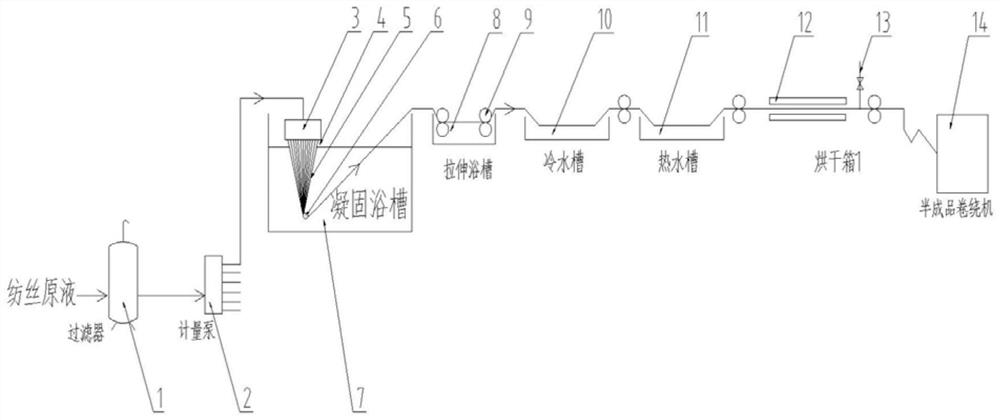

[0032] A smooth-surfaced meta-aramid filament and a preparation method thereof, the steps of which are:

[0033] (1) Synthesizing a meta-aromatic polyamide compound solution with m-phenylene isophthalamide as a repeating unit earlier to obtain a meta-aramid fiber spinning stock solution;

[0034] Wherein, the meta-aromatic polyamide compound solution with m-phenylene isophthalamide as the repeating unit is subjected to a low-temperature polycondensation reaction at an equimolar ratio of m-phenylene diamine and isophthaloyl chloride. Preferably, the reaction The temperature is -12°C to 0°C, and the viscosity range of the meso-aramid spinning stock solution is 300-1500Po.

[0035] (2) The above-mentioned stock solution is transported into a high-precision filter through a gear pump, and the filtered stock solution is transported to the spinneret assembly by a metering pump, and enters the air gap layer through the spinneret holes on the spinneret assembly to form;

[0036] Amon...

Embodiment 1

[0053] The synthetic isophthaloyl dichloride m-phenylenediamine spinning stock solution with a viscosity of 300Po is filtered through a 30-micron precision filter and then sent into a metering pump. The output flow of each metering pump is 15ml / min. The silk hole then enters the 3mm air gap, and passes through the coagulation bath with the temperature of -5°C and the concentration of N,N-dimethylacetamide of 10% and the temperature of 0°C and the concentration of N,N-dimethylacetamide of 15%. Stretch bath liquid, adjust the rotational speed ratio of the press roller before and after the stretching bath and set the stretching ratio as 1.2 times. The stretched filaments are washed in cold water in a cold water bath with a temperature of 10°C and a concentration of N,N-dimethylacetamide of 2% in sequence, and in a hot water bath with a temperature of 50°C for hot water washing, and the direction of water flow is consistent with the direction of filament advancement. on the contra...

Embodiment 2

[0056] The synthetic isophthaloyl dichloride m-phenylenediamine spinning stock solution with a viscosity of 1500Po is filtered through a 30-micron precision filter and then sent into the metering pump. The silk hole then enters the 10mm air gap, passes through a coagulation bath with a temperature of 38°C and a concentration of N,N-dimethylacetamide of 60% and a stretching bath with a temperature of 38°C and a concentration of N,N-dimethylacetamide of 58% Bath liquid, adjust the rotational speed ratio of the press rollers before and after the stretching bath and set the stretching ratio to 4.9 times. The stretched filaments are washed in cold water in an aqueous solution with a temperature of 20°C and a concentration of N,N-dimethylacetamide of 30%, followed by hot water washing in a hot water bath with a temperature of 80°C, and the direction of water flow is consistent with the direction of filament advancement on the contrary. After washing, the filaments are dried in a dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com