Calcium carbonate inhibitor, preparation method and application thereof

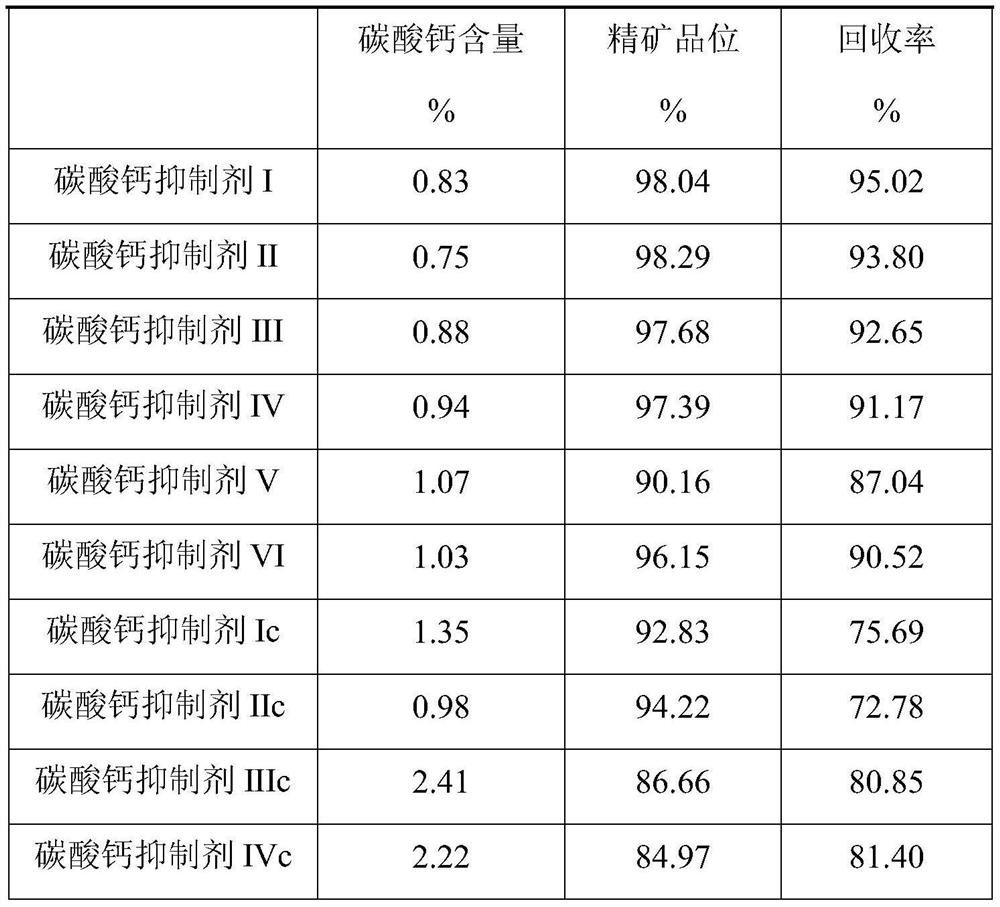

A technology of calcium carbonate and inhibitor, which is applied in the direction of solid separation and flotation, can solve the problems that the products cannot meet the requirements of industrial grade, the recovery rate of ore dressing is low, and the content of calcium carbonate is high, so as to achieve good selectivity and inhibition, and environment-friendly Pollution, the effect of improving recovery rate of beneficiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

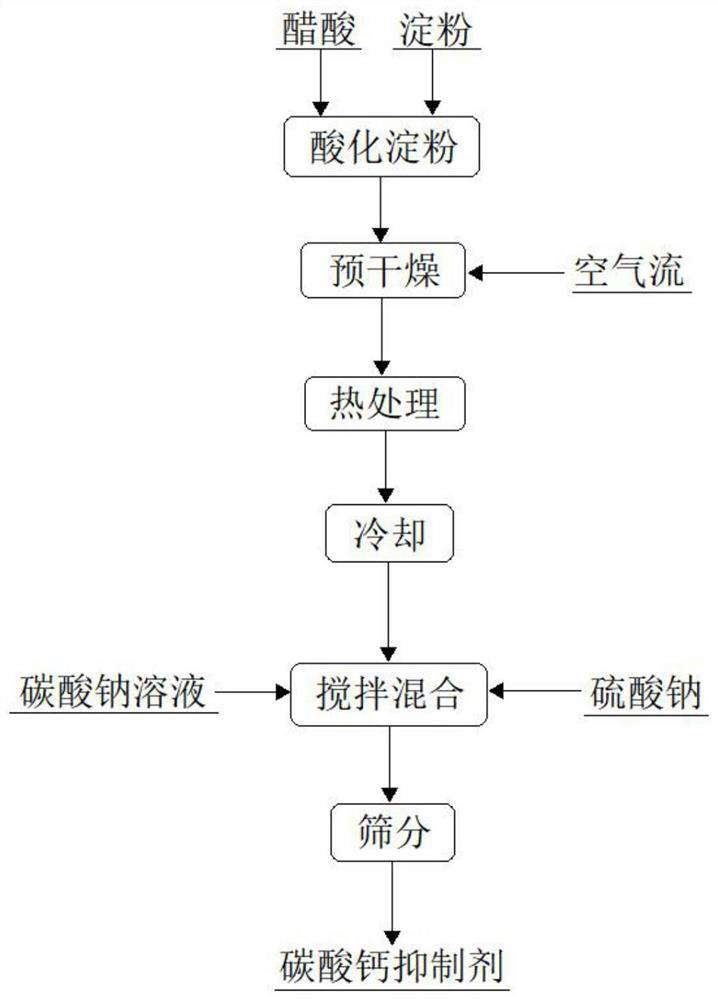

[0054] Add 75 parts of starch into the mixer, and adjust the stirring rate of the mixer to 70r / min. Then 0.72 parts of acetic acid (10 wt% acetic acid solution) was added to the starch by spraying or spraying. After the addition was completed, the stirring was continued for 10 min to obtain acidified starch.

[0055] The acidified starch is placed in a pre-dryer, and the acidified starch is pre-dried for 30 minutes by air flow at 25°C. Then place the pre-dried acidified starch in a roaster for heat treatment at 160° C. for 2 hours, and after the roasting is completed, cool to room temperature overnight to obtain a dry material.

[0056] Add the dry material to the mixer, then add 1.47 parts of sodium carbonate (10wt% sodium carbonate solution) to the dry material by spraying or spraying, and add 22.81 parts of anhydrous sodium sulfate to the mixer, and continue stirring Mix evenly, and obtain powdered calcium carbonate inhibitor I after sieving.

Embodiment 2

[0058] Add 75 parts of starch into the mixer, and adjust the stirring rate of the mixer to 70r / min. Then 0.72 parts of acetic acid (12 wt% acetic acid solution) was added to the starch by spraying or spraying. After the addition was completed, the stirring was continued for 10 min to obtain acidified starch.

[0059] The acidified starch is placed in a pre-dryer, and the acidified starch is pre-dried for 30 minutes by air flow at 25°C. Then place the pre-dried acidified starch in a roaster for heat treatment at 170° C. for 2 hours. After the roasting is completed, cool to room temperature overnight to obtain a dry material.

[0060] Add the dry material to the mixer, then add 1.96 parts of sodium carbonate (10wt% sodium carbonate solution) to the dry material by spraying or spraying, and add 22.32 parts of anhydrous sodium sulfate to the mixer, and continue stirring Mix evenly and sieve to obtain powdered calcium carbonate inhibitor II.

Embodiment 3

[0062] Add 74 parts of starch into the mixer, and adjust the stirring rate of the mixer to 80r / min. Then 0.9 parts of acetic acid (15 wt% acetic acid solution) was added to the starch by spraying or spraying. After the addition was completed, the stirring was continued for 10 min to obtain acidified starch.

[0063] The acidified starch is placed in a pre-dryer, and the acidified starch is pre-dried for 30 minutes by air flow at 25°C. Then place the pre-dried acidified starch in a roaster for heat treatment at 180° C. for 2 hours, and after the roasting is completed, cool to room temperature overnight to obtain a dry material.

[0064] Add the dry material to the mixer, then add 1.96 parts of sodium carbonate (12wt% sodium carbonate solution) to the dry material by spraying or spraying, and add 23.14 parts of anhydrous sodium sulfate to the mixer, and continue stirring Mix evenly and sieve to obtain powdered calcium carbonate inhibitor III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com