Preparation method for super-hydrophilic metal/high-entropy ceramic composite antibacterial coating

A ceramic composite and antibacterial coating technology, which is applied in metal material coating technology, coating, ion implantation plating, etc., can solve the problems of insufficient antibacterial performance and bone healing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

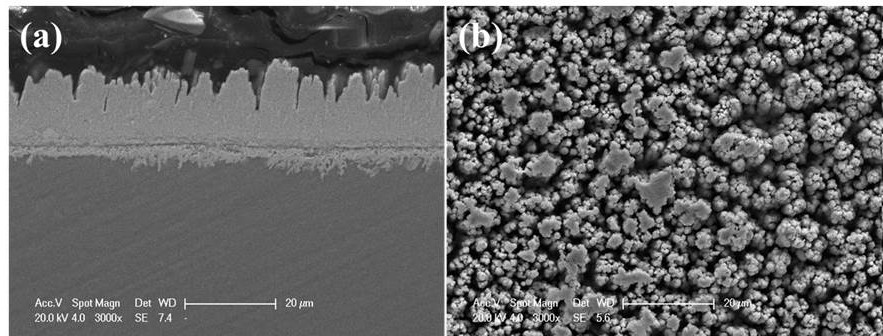

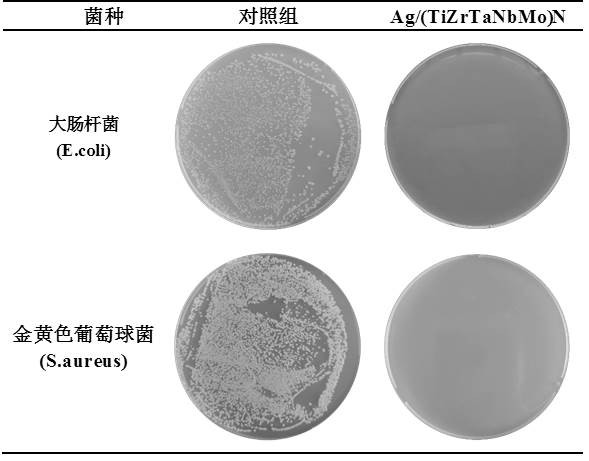

[0021] The substrate is made of medical grade pure titanium (grade: TA2), the sample size is 10mm×10mm×3mm, and the pre-coated surface size is 10mm×10mm. The surface of the substrate is sanded, polished, degreased, cleaned and dried step by step with sandpaper, and then put into a desiccator for later use.

[0022] The source target was prepared by hot pressing and sintering, and the components of the target were prepared in molar ratio: 5% Ag, 19% Ti, 19% Zr, 19% Nb, 19% Ta, 19% Mo.

[0023] Place the substrate and the target on the source and workpiece sample holders of the dual-cathode plasma reaction deposition furnace respectively, and adjust the process parameters as follows: the target voltage is 850V, the workpiece voltage is 300V, the distance between the target and the workpiece is 10mm, argon / The nitrogen flow ratio is 10:1, the working pressure is 40Pa, the deposition temperature is 850°C, and the deposition time is 3.5h. After the deposition, the sample was take...

Embodiment 2

[0028] The substrate is made of medical-grade titanium alloy (grade: TC4), the sample size is φ30mm×3mm, and the surface size of the pre-deposited coating is φ30mm. The surface of the substrate is sanded, polished, degreased, cleaned and dried step by step with sandpaper, and then put into a desiccator for later use.

[0029] The source target is prepared by hot pressing and sintering, and the components of the target are formulated in molar ratio as follows: 15At% Ag, 17At% Ti, 17At% Zr, 17At% Nb, 17At% Ta, 17At% Mo.

[0030] Place the substrate and the target on the source and workpiece sample holders of the dual-cathode plasma reaction deposition furnace respectively, and adjust the process parameters as follows: the target voltage is 800V, the workpiece voltage is 300V, the distance between the target and the workpiece is 10mm, argon / The nitrogen flow ratio is 10:1, the working pressure is 40Pa, the deposition temperature is 850°C, and the deposition time is 3h.

[0031]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com