Fluffy carbon-coated silicon composite material, and preparation method and application thereof

A silicon composite material, carbon coating technology, applied in carbon preparation/purification, nanotechnology for materials and surface science, silicon, etc., can solve problems such as electrode failure, achieve low residual carbon rate, and achieve commercialization , the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a fluffy carbon-coated silicon composite material, the specific steps are as follows:

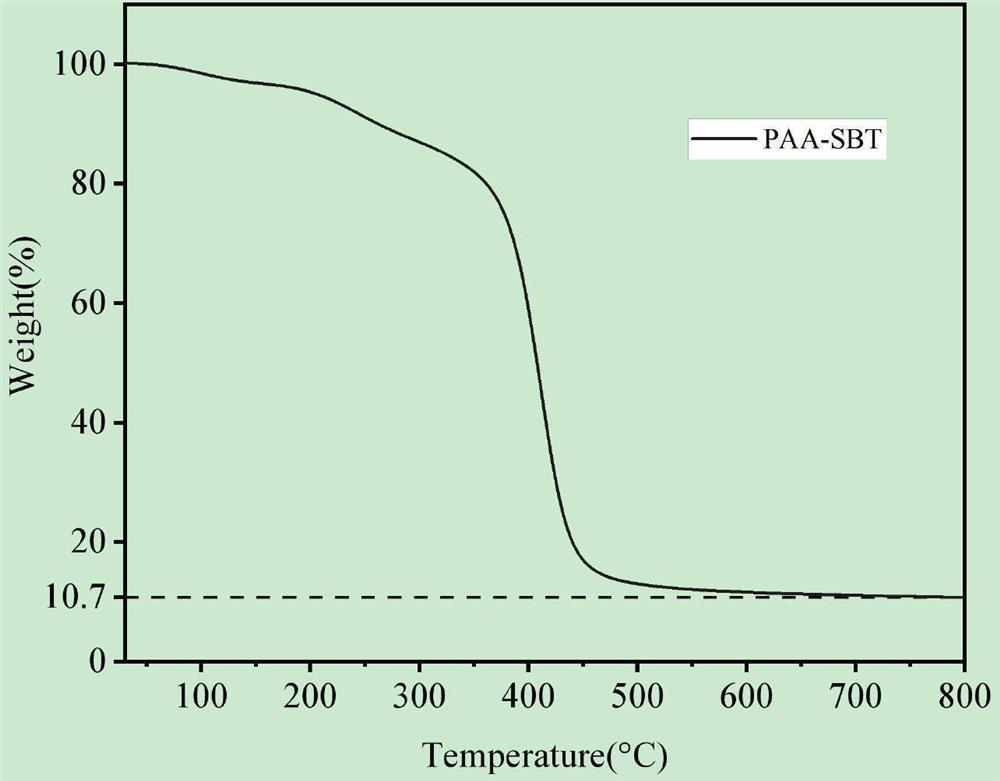

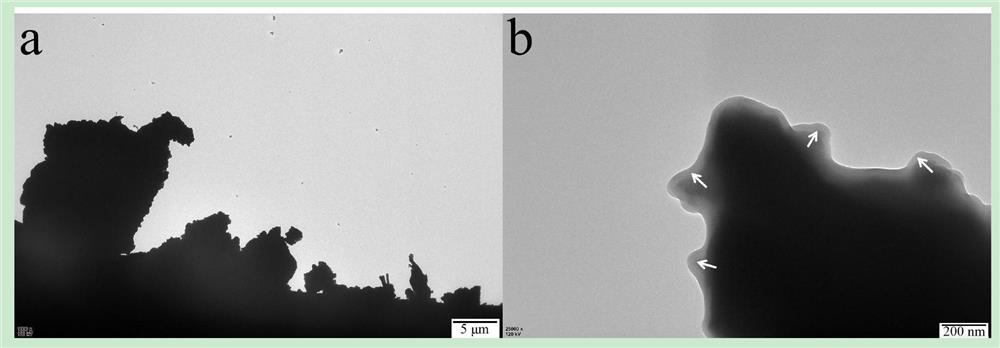

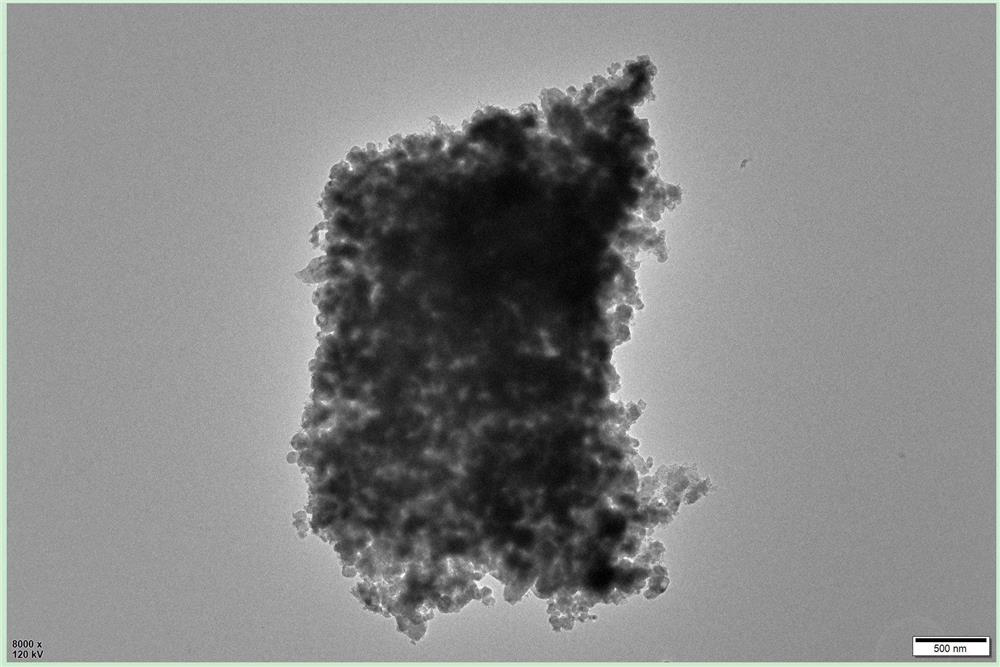

[0034] 100 mg of polyacrylic acid and 66.7 mg of sorbitol were dissolved in a mixed solution consisting of 5 mL of water and 15 mL of ethanol. Add 200mg of silicon particles with a particle size of 100nm to the above solution, then stir for 5min and sonicate for 30min, then place in a water bath at 80°C to remove the solvent. After removing the solvent, the material was ground for 10 min and placed in an inert atmosphere, heated to 150 °C at a heating rate of 5 °C / min and maintained for 4 h, then removed and ground for 15 min after the temperature dropped to <50 °C. Take 60mg of ground powder and disperse it in 10mL of ethanol, then add 100mg of phenolic resin. The mixture was stirred for 5 minutes and then ultrasonicated for 10 minutes, and then placed in a water bath at 80° C. to evaporate ethanol. The material after removal of ethanol was ground for 10 min...

Embodiment 2

[0038] A method for preparing a silicon-carbon hollow core-shell structure composite material, the specific steps are as follows:

[0039] 200 mg of polyacrylic acid and 133.3 mg of sorbitol were dissolved in a mixed solution consisting of 5 mL of water and 15 mL of ethanol. Add 200mg of silicon particles with a particle size of 100nm to the above solution, then stir for 5min and sonicate for 30min, then place in a water bath at 80°C to remove the solvent. After removing the solvent, the material was ground for 10 min and placed in an inert atmosphere, heated to 200 °C at a heating rate of 5 °C / min and maintained for 3 h, then removed and ground for 15 min after the temperature dropped to <50 °C. Take 60mg of ground powder and disperse it in 10mL of ethanol, then add 100mg of phenolic resin. The mixture was stirred for 5 min and then ultrasonicated for 10 min, and spread on a polyethylene film at 50°C to evaporate ethanol. Since polyethylene will completely decompose at abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com