Thermoplastic resin, molded object, and monomer for thermoplastic resin

A thermoplastic resin and molded body technology, applied in the field of thermoplastic resin monomers, can solve the problems of high material cost, practical obstacles, high technology, etc., and achieve the effect of excellent optical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0270] Hereinafter, the present invention will be described by way of examples, but the present invention is not limited by these examples. In addition, the measured values in the examples were measured by the following methods or devices.

[0271] (1) Weight average molecular weight (Mw)

[0272] A calibration curve was prepared by gel permeation chromatography (GPC) using tetrahydrofuran as a developing solvent and standard polystyrene with known molecular weight (molecular weight distribution=1). Calculated from the retention time of GPC based on this calibration curve.

[0273] (2) Refractive index nd

[0274] The resin is press-molded (molding conditions: 200°C, 100kgf / cm 2 , 2 minutes) into a circular plate with a diameter of 40 mm and a thickness of 3 mm, cut out a test piece at a right angle, and use a precision refractometer (manufactured by Shimadzu Corporation, product name "KPR-200") for the test piece. Determination.

[0275] (3) Glass transition temperatur...

manufacture example 1

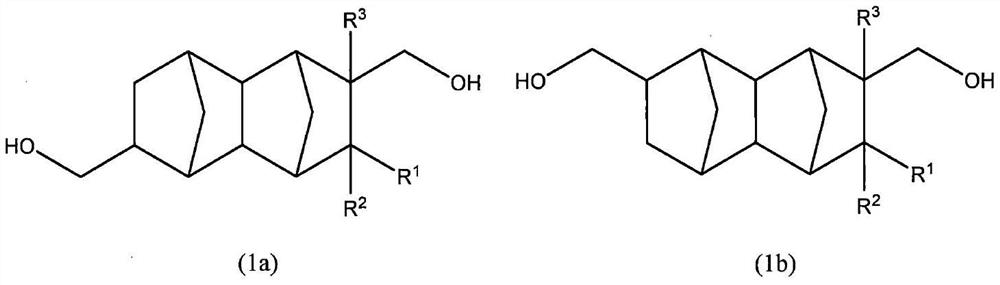

[0292] Production Example 1 (Synthesis of D-NDM-Me)

[0293] The synthesis scheme of D-NDM-Me is as follows.

[0294]

[0295] In addition, the conditions of the gas chromatography measurement and GC-MS measurement of the product obtained by each process of manufacture example 1 are as follows.

[0296] (1) Gas Chromatography Determination Conditions

[0297] ・Analyzer: Shimadzu Corporation, Capillary Gas Chromatograph GC-2010Plus

[0298] ・Analytical column: manufactured by GL Sciences Inc., InertCap1 (30 m, 0.32 mm I.D., film thickness 0.25 μm)

[0299] Oven temperature: 60°C (0.5 minutes) - heating rate 15°C / min - 280°C (4 minutes)

[0300] ·Detector: FID, temperature 280°C

[0301] (2) GC-MS measurement conditions

[0302] ・Analyzer: Shimadzu Corporation, GCMS-QP2010 Plus

[0303] ·Ionization voltage: 70eV

[0304] Analytical column: manufactured by Agilent Technologies Co., Ltd., DB-1 (30m, 0.32mm I.D., film thickness 1.00μm)

[0305] Oven temperature: 60°C (0.5 ...

Embodiment 1

[0321] Diphenyl carbonate and 20.0mg (6.0×10 -5 mol) of tetrabutoxytitanium were added to a 500mL reactor equipped with a stirrer and a distillation device, and nitrogen gas was introduced into the system, and heated to 180°C for 1 hour while stirring under a nitrogen atmosphere of 101.3kPa. Then, after reaching 180°C, while decompressing to 40kPa over 30 minutes, the temperature was raised to 255°C over 2 hours from the start of depressurization, and when the distilled methanol and phenol reached 60%, the pressure was further increased for 1 hour. Reduce the pressure to below 0.133kPa. Then, it was held at 0.133 kPa or less for 30 minutes to obtain a polycarbonate resin (1).

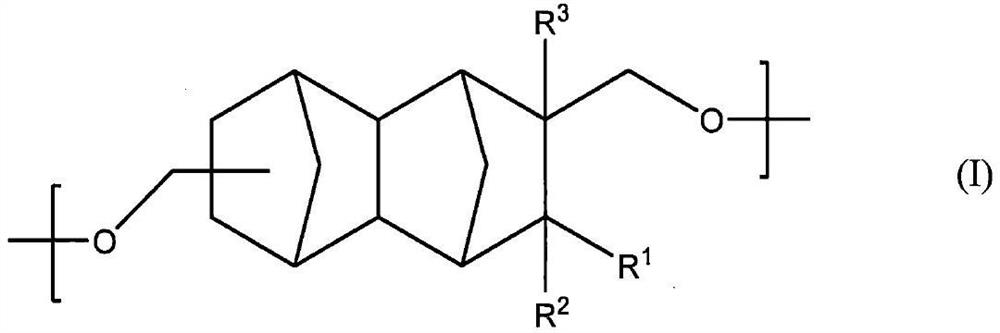

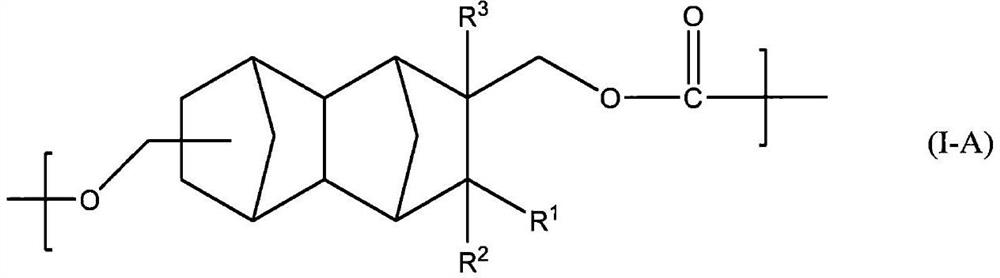

[0322] Polycarbonate resin (1) is to have the structural unit shown in above-mentioned general formula (IA) (wherein, R 1 is methyl, R 2 and R 3 is a polymer of Mw=28,000).

[0323] Furthermore, the physical properties of the polycarbonate resin (1) are refractive index nd: 1.525, Tg: 127°C, specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| photoelasticity | aaaaa | aaaaa |

| photoelasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com