Oil displacement aid and its preparation method and application

A technology of drainage aid and oil displacement, which is applied in the preparation of ether, sulfonic acid, and sulfate, etc., and can solve the problems of limited and poor development effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

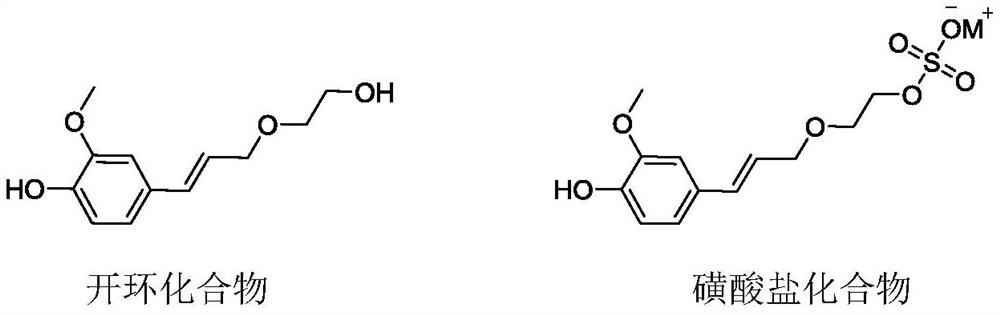

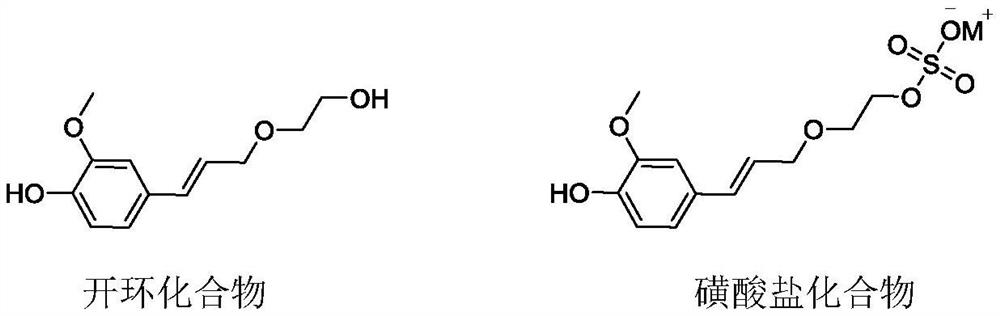

[0020] In a typical embodiment of the present application, a method for preparing an oil-displacing aid is provided, the preparation method comprising: step S1, mixing coniferyl alcohol, ethylene oxide and a first solvent under alkaline conditions The ring-opening reaction is carried out to obtain a ring-opening compound; in step S2, the ring-opening compound, SO 3 and a second solvent to carry out sulfonation reaction to obtain a sulfonate compound; step S3, mixing the sulfonate compound and a surface active substance to obtain an oil displacement aid; wherein, the surface active substance is a fluorocarbon surfactant and carbonic acid The mixture of ammonium hydrogen, the ring-opening compound and the sulfonate compound respectively have the following structural formulas:

[0021]

[0022] M + is a monovalent cation.

[0023] The application utilizes coniferyl alcohol and ethylene oxide in alkaline conditions (M + Ring-opening reaction occurs under the cation from basi...

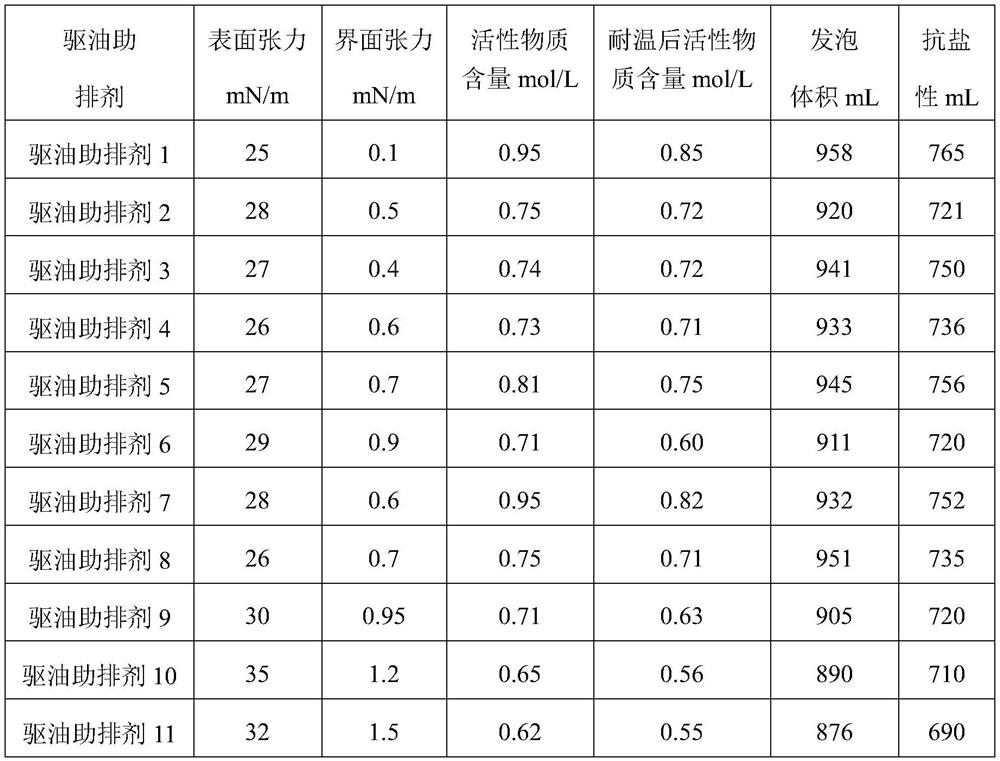

Embodiment 1

[0039] Take 1 g of coniferyl alcohol, 2 g of ethylene oxide, and 0.1 g of sodium hydroxide in a 25 mL three-necked flask, add 10 mL of dioxane solvent, and carry out a ring-opening reaction at 80 ° C for 5 h. At room temperature, water was added for 3 washings to obtain a product system containing the ring-opening compound; the product system containing the ring-opening compound was mixed with 0.5 g SO 3 , 10mL of dioxane solvent was subjected to sulfonation reaction at room temperature for 6h, and then extracted to obtain sodium sulfonate compound; 0.1g of fluorocarbon surfactant and 2g of ammonium bicarbonate were mixed uniformly to obtain a surface active substance, and then 0.3 g of sodium sulfonate compound and 0.2 g of surface active substance were mixed uniformly to obtain oil displacement aid 1.

Embodiment 2

[0041] Take 1 g of coniferyl alcohol, 1 g of ethylene oxide, 0.15 g of sodium hydroxide, and carry out a ring-opening reaction at 85 ° C for 4 hours. After the temperature of the system is lowered to room temperature, water is added and washed three times to obtain a ring-opening reaction containing The product system of the compound; the product system containing the ring-opening compound is obtained; the obtained product system containing the ring-opening compound is mixed with 1 g SO 3 , 10mL of dioxane solvent was subjected to sulfonation reaction at room temperature for 4h, and then extracted to obtain sodium sulfonate compound; 0.1g of fluorocarbon surfactant and 2g of ammonium bicarbonate were mixed uniformly to obtain a surface active substance, and then Take 0.3 g of sodium sulfonate compound and 0.2 g of surface active substance and mix it uniformly to obtain oil displacement aid 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com