Protease K freeze-drying protective agent and preparation method thereof

A freeze-drying protective agent and protease technology, applied in biochemical equipment and methods, freeze-drying transportation, peptide/protein components, etc., can solve the problems of cumbersome preparation process, achieve good solubility, good appearance, and improve storage stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] The separation and purification of embodiment 1 proteinase K

[0088]Extracting proteinase K: using yeast secretion expression or other expression systems to prepare proteinase K, the proteinase K supernatant in the lower tank of fermentation (the supernatant of proteinase K-containing fermentation products after centrifugation to remove microbial cells) can be obtained in the following ways Purified enzyme solution.

[0089] 1. Coarse separation:

[0090] (a) Salting-out method: using ammonium sulfate to fractionally precipitate proteins. First, prepare a saturated ammonium sulfate solution (usually the saturation is 33% to 50%), slowly add an equal volume of saturated ammonium sulfate solution to the protein supernatant with a protein concentration of 20 mg / mL while stirring, and place the solution at 4 ℃, stir with a magnetic stirrer for 6 hours or overnight to fully precipitate the protein; centrifuge the protein solution at 12,000g at 4°C for 20min, discard the s...

Embodiment 2

[0096] The preparation method of embodiment 2 freeze-dried powder:

[0097] The purified enzyme solution prepared in Example 1 is mixed alone or with a protective agent, and poured into a clean and sterile glass plate with a glass bottom diameter of 14 cm to ensure that the liquid level is no more than 1 cm to ensure the best sublimation effect (liquid level too high, too much liquid volume will affect the sublimation efficiency), and then freeze-dried on the plate layer of the freeze dryer.

[0098] The freeze dryer program is set as follows;

[0099] a. Pre-freezing stage: set the layer temperature at -45°C for 2.5 hours; annealing temperature at -25°C for 2 hours; then lower the temperature to -45°C for 3 hours; return temperature to 1°C / min;

[0100] b. Primary sublimation: set the vacuum value below 20pa, rise from -45°C to -18°C in step a for 22 hours; in the second stage, the temperature of the sheet layer rises to -15°C, and the duration is 12h; in the third stage, th...

Embodiment 3

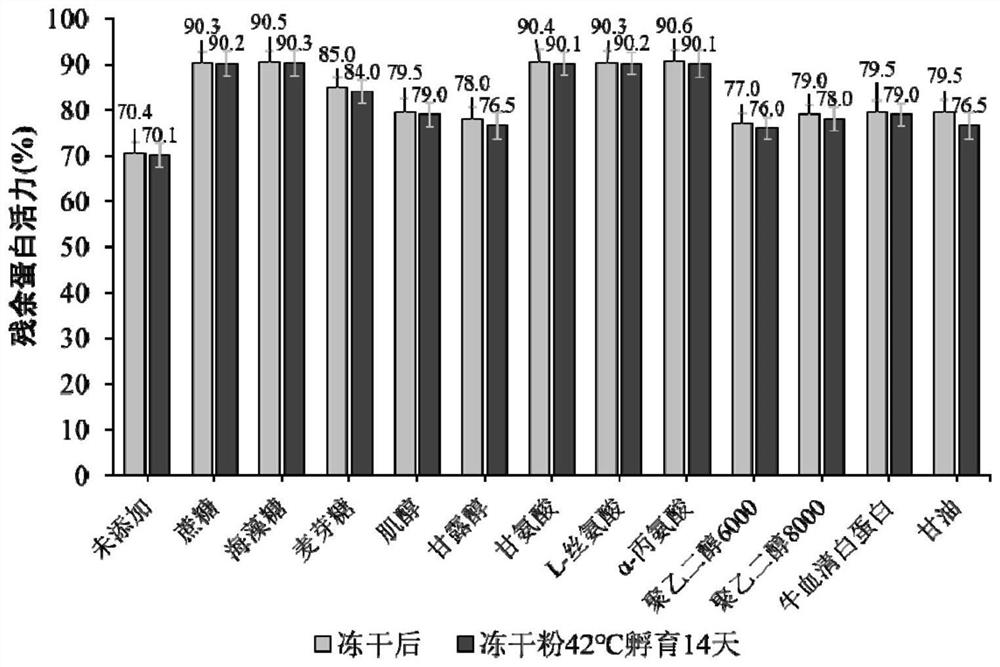

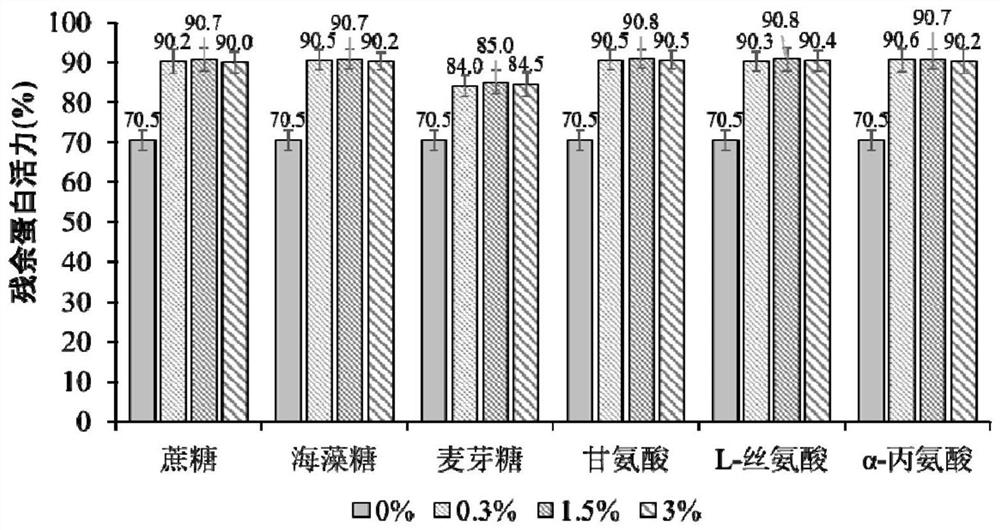

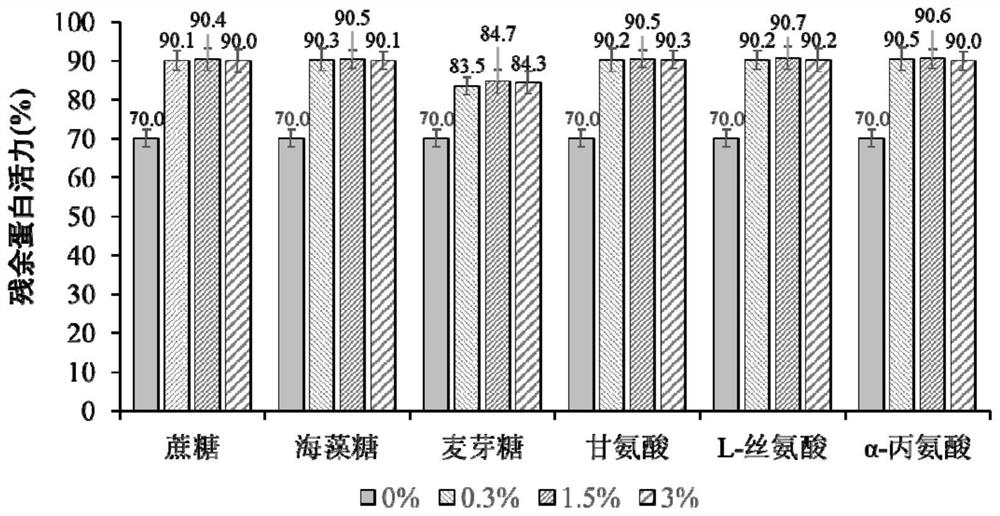

[0103] Example 3 Screening of lyoprotectant components and preparation of lyophilized enzyme powder

[0104] In 50mM pH7.0 HEPES buffer, sucrose, trehalose, maltose, inositol, glycine, L-serine, α-alanine, PEG6000, PEG8000, BSA and glycerol were used as lyoprotectants respectively, and the specific activity Proteinase K with a concentration of 48U / mg and a concentration of 60mg / mL was mixed with an equal volume of 30mg / mL sucrose, 30mg / mL trehalose, 30mg / mL maltose, 30mg / mL inositol, 30mg / mL glycine, 30mg / mL L-serine, 30mg / mL α-alanine, 3mg / ml PEG6000, 3mg / ml PEG8000, 30mg / ml BSA, 20% glycerol were mixed, and 1‰ volume of 1M CaCl was added 2 Solution, so that the final concentration of proteinase K in the solution is 30mg / mL, the final concentration of buffer solution HEPES (pH 7.0) is 50mM, Ca 2+ The concentration is 5mM. The freeze-dried enzyme powder was prepared according to the steps in Example 2, and the enzyme activity of the freeze-dried enzyme powder and the proteas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| buffering capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com