Preparation method of nano zero-valent iron loaded porous carbon composite material uranium adsorbent

A technology of nano-zero-valent iron and composite materials, applied in chemical instruments and methods, other chemical processes, nuclear engineering, etc., can solve the problems of poor adsorption effect and low adsorption rate, increase stability and specific surface area, improve Adsorption rate, effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

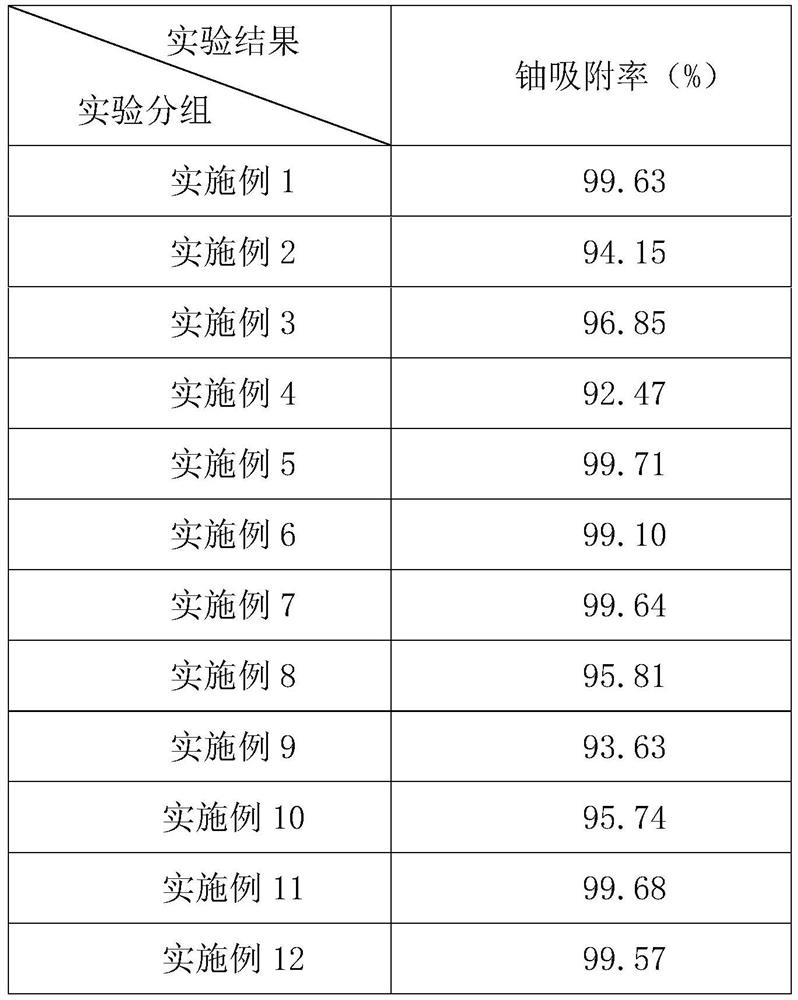

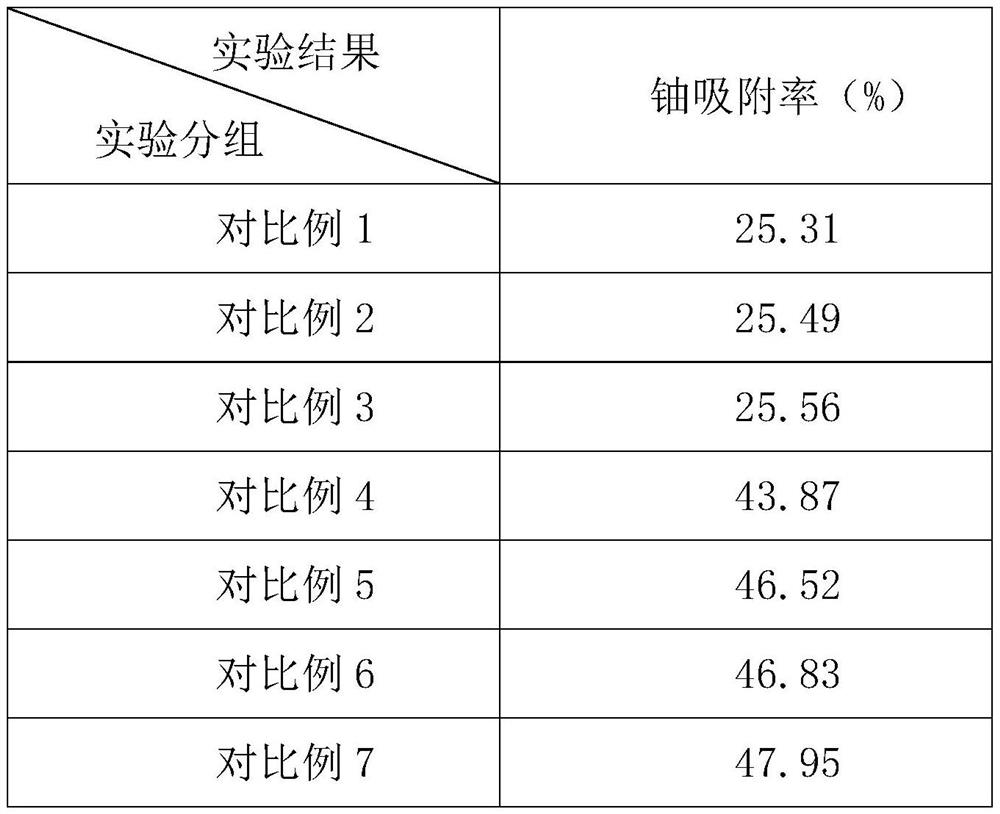

Examples

Embodiment 1

[0023] The invention provides a method for preparing a porous carbon composite uranium adsorbent loaded with nanometer zero-valent iron. The preparation method comprises the following steps:

[0024] S1: Mix 12ml of styrene and 320ml of deionized water and heat to 70°C. In an atmosphere of argon as a protective gas, add 10ml of 0.3M potassium persulfate aqueous solution, stir at 60rpm and keep at 70°C for 28h. A white emulsion was formed, and the emulsion was centrifugally filtered, washed three times with deionized water and ethanol, and dried at 30°C for 4 hours to obtain white powdery polystyrene microspheres;

[0025] S2: Disperse 20g of dried polystyrene microspheres in 300ml of isopropanol solution, stir at 80rpm for 3h, then add 4g of titanium tetraisopropoxide and 2g of terephthalic acid, continue to stir at the same speed for 4h, at 70°C Drying at 600°C for 2h in a tube furnace in an atmosphere of nitrogen as a protective gas, with a heating rate of 2°C / min, to obtain...

Embodiment 2

[0028] The invention provides a method for preparing a porous carbon composite uranium adsorbent loaded with nanometer zero-valent iron. The preparation method comprises the following steps:

[0029] S1: Mix 12ml of styrene and 320ml of deionized water and heat to 70°C. In an atmosphere of argon as a protective gas, add 10ml of 0.3M potassium persulfate aqueous solution, stir at 60rpm and keep at 70°C for 28h. A white emulsion was formed, and the emulsion was centrifugally filtered, washed three times with deionized water and ethanol, and dried at 30°C for 4 hours to obtain white powdery polystyrene microspheres;

[0030] S2: Disperse 20g of dried polystyrene microspheres in 300ml of isopropanol solution, stir at 80rpm for 3h, then add 4g of titanium tetraisopropoxide and 2g of terephthalic acid, continue to stir at the same speed for 4h, at 70°C Drying at 600°C for 2h in a tube furnace in an atmosphere of nitrogen as a protective gas, with a heating rate of 2°C / min, to obtain...

Embodiment 3

[0033] The invention provides a method for preparing a porous carbon composite uranium adsorbent loaded with nanometer zero-valent iron. The preparation method comprises the following steps:

[0034] S1: Mix 12ml of styrene and 320ml of deionized water and heat to 70°C. In an atmosphere of argon as a protective gas, add 10ml of 0.3M potassium persulfate aqueous solution, stir at 60rpm and keep at 70°C for 28h. A white emulsion was formed, and the emulsion was centrifugally filtered, washed three times with deionized water and ethanol, and dried at 30°C for 4 hours to obtain white powdery polystyrene microspheres;

[0035] S2: Disperse 20 g of dried polystyrene microspheres in 300 ml of isopropanol solution, stir at 80 rpm for 3 h, add 4 g of titanium tetraisopropoxide and 2 g of terephthalic acid, continue stirring at the same speed for 4 h, and Drying at 600°C for 2h in a tube furnace in an atmosphere of nitrogen as a protective gas, with a heating rate of 2°C / min, to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com