Sludge pretreatment method based on sulfo-porphyrin iron catalyst Fenton-like system

A sulfonic porphyrin iron, catalyst technology, applied in water/sludge/sewage treatment, oxidation treatment of sludge, chemical instruments and methods, etc., can solve the problem of limited hydrolysis capacity of sludge, hydroxyl-substituted chloride ions and peroxide The problems of hindered hydrogen coordination and difficult high-valent iron oxide species can achieve the effect of improving subsequent resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

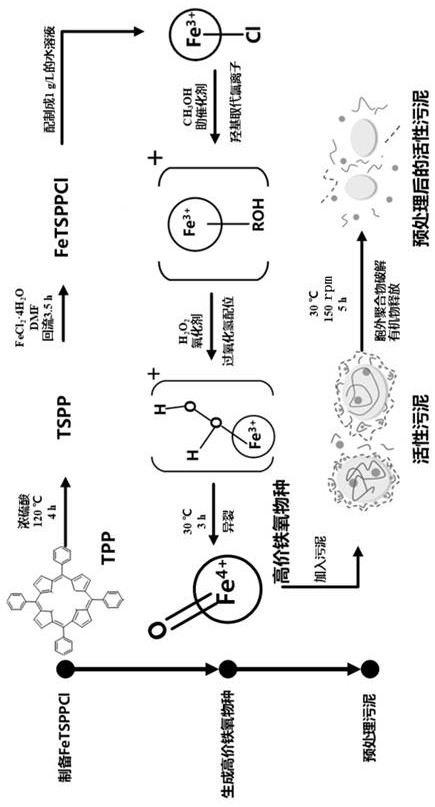

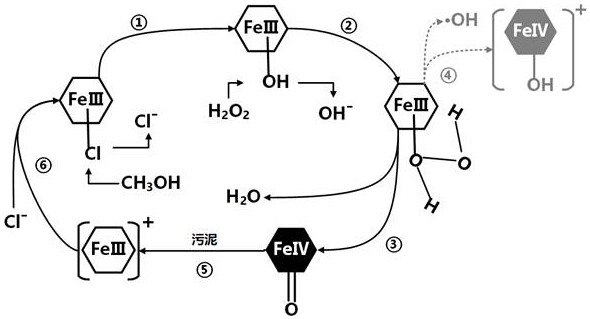

[0039] A kind of sludge pretreatment method based on sulfonic acid group porphyrin iron catalyst Fenton system, its process flow chart is as follows figure 1 shown, including the following steps:

[0040] S1. Prepare a sulfonic acid porphyrin iron catalyst (tetrakis(4-sulfonic acid phenyl) porphyrin ferric chloride, FeTSPPCl) into an aqueous solution with a concentration of 1 g / L, take 1 mL into the reactor, and pour to Add 0.36 mL of anhydrous methanol and 2.5 mL of hydrogen peroxide solution with a mass concentration of 30% into the reactor, and stir. Specifically, place the reactor in a shaker at 30°C for 3 hours to fully shake and react to obtain a mixed solution.

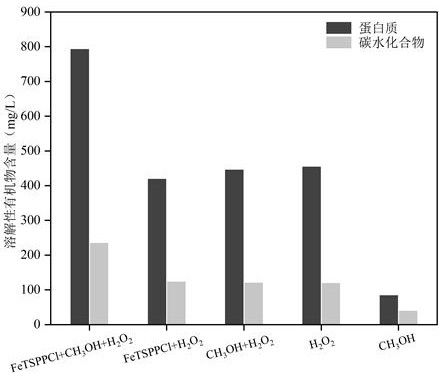

[0041] S2. Add 100 mL of activated sludge (TSS=40.39 g / L, pH=6.98) into the reactor containing the mixed solution in step S1 for hydrolysis treatment. Specifically, use a sealing film to bind the mouth of the reactor bottle, and at the same time put The reactor was incubated in a constant temperature shaking i...

Embodiment 2

[0070] A kind of sludge pretreatment method based on sulfonic acid porphyrin iron catalyst class Fenton system, comprises the following steps:

[0071] S1. Prepare the iron sulfonate porphyrin catalyst (tetrakis(4-sulfonate phenyl)porphyrin ferric chloride, FeTSPPCl) prepared in Example 1 into an aqueous solution with a concentration of 1 g / L, and take 0.1 mL , 2mL, 4mL, and 8mL were respectively placed in different reactors, and 0.36 mL of anhydrous methanol, 2.5 mL of hydrogen peroxide solution with a mass concentration of 30% were added to these reactors in turn, and stirred. Specifically, the reactor Placed in a shaker at 30°C for 3 h to fully shake the reaction to obtain a mixed solution.

[0072] S2. Add 100 mL of activated sludge (TSS=40.39 g / L, pH=6.98) into different reactors containing mixed liquid in step S1 (the corresponding concentrations of FeTSPPCl in these reactors are 0 mg / L, 10 mg / L, 20mg / L, 40mg / L, 80mg / L) for hydrolysis treatment, specifically, the bottl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com