Solid-state polyelectrolyte for lithium battery and preparation method of solid-state polyelectrolyte

A solid electrolyte and polyelectrolyte technology, which is applied in the field of polyether-polyamide block copolymer solid electrolyte and its preparation, solid polyelectrolyte and its preparation field, can solve problems such as Li+ transport obstacles, and achieve fast transport, source The effect of broad, good film formation and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

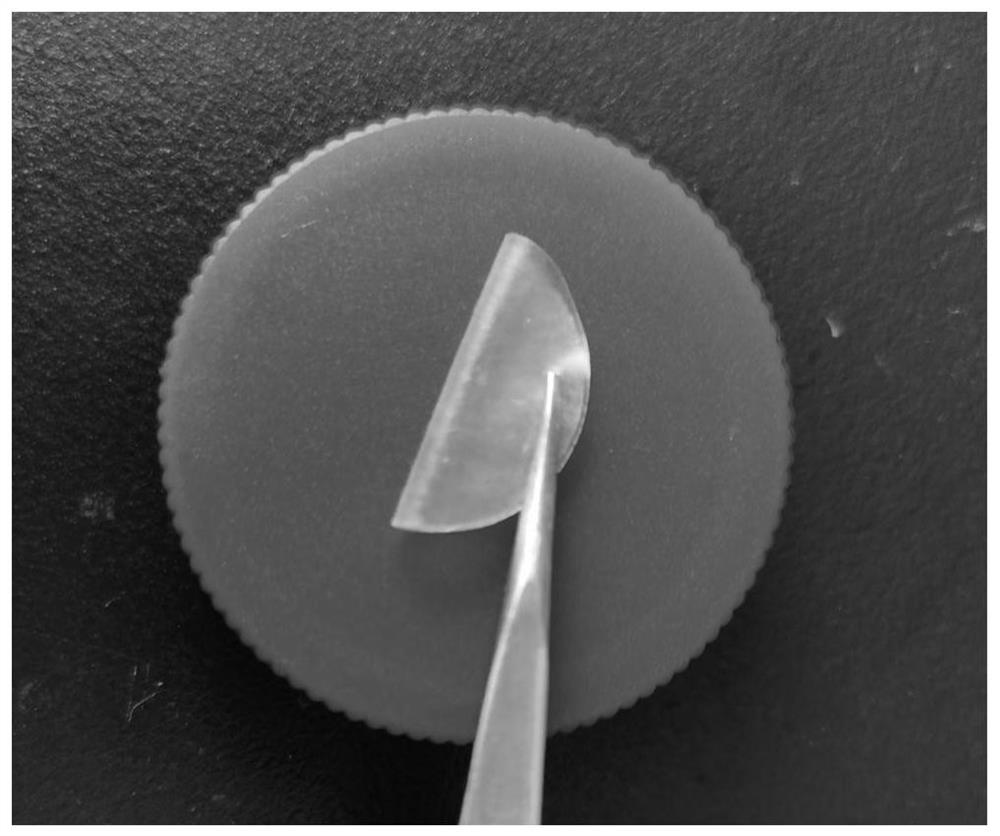

Image

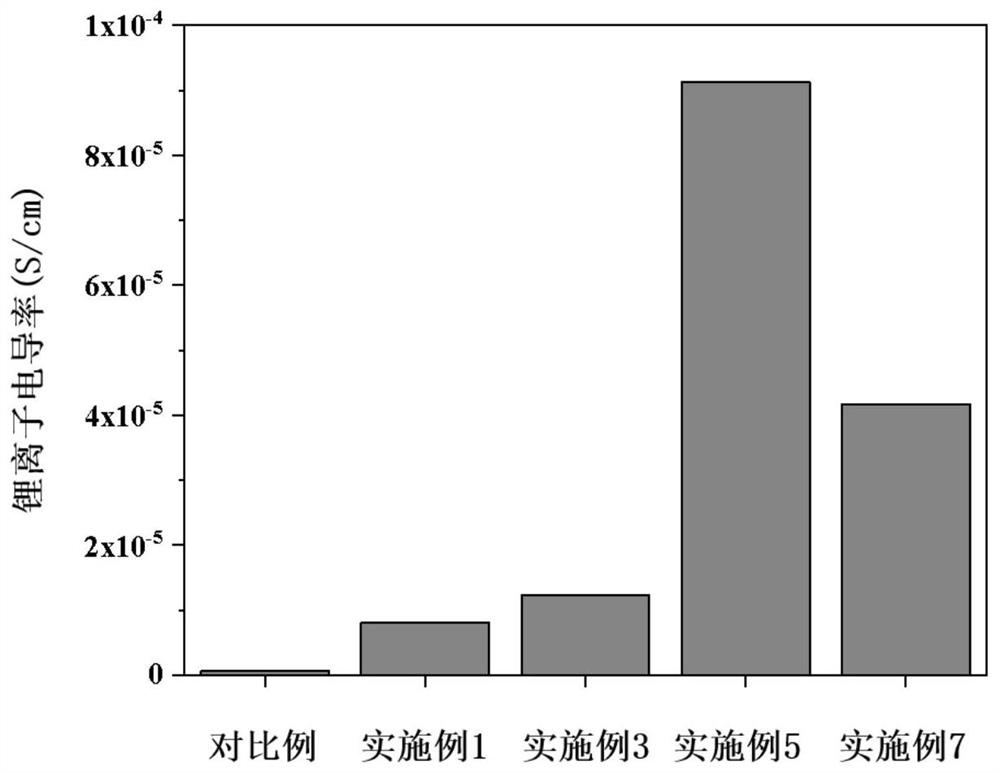

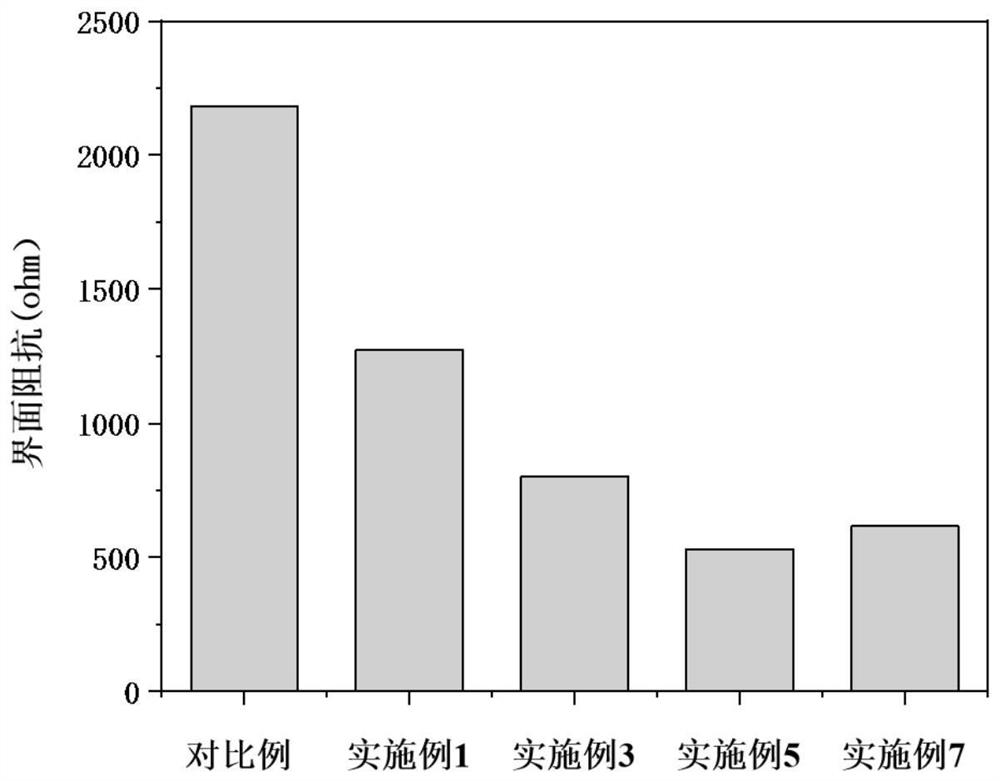

Examples

Embodiment 1

[0033] 1) Preparation of polyethylene oxide-polycaprolactam copolymer

[0034] Add carboxy-terminated polycaprolactam (molecular weight 4000) into the polymerization kettle, then add 60% by mass percentage of hydroxyl-terminated polyethylene oxide (molecular weight 2000) and 0.4% of the total mass of the matrix as a catalyst tetrabutyl titanate, vacuum- Inflate with nitrogen for 7 minutes each, and cycle three times. After heating under the protection of nitrogen until the raw materials are completely melted, turn on the stirring paddle. After reacting for 5 hours, vacuumize to remove unreacted monomers and a small amount of water produced by copolymerization, keep the vacuum <800Pa and continue the reaction for 1 hour, and discharge when the relative viscosity of the product is 1.36 to obtain polyethylene oxide-polycaprolactam intercalated Segment copolymer;

[0035] 2) Preparation of polyelectrolyte casting solution

[0036] Weigh 5g of the polyethylene oxide-polycaprolact...

Embodiment 2

[0041] 1) Preparation of polybutylene oxide-polycaprolactam copolymer

[0042] Add carboxyl-terminated polycaprolactam (molecular weight 4000) into the polymerization kettle, then add 75% mass percent of hydroxyl-terminated polybutylene oxide (molecular weight 5000) and 0.6% catalyst propyl titanate of the total mass of the matrix, vacuum- Inflate with nitrogen for 7 minutes each, and cycle three times. After heating under the protection of nitrogen until the raw materials are completely melted, turn on the stirring paddle. After reacting for 4 hours, vacuumize to remove unreacted monomers and a small amount of water produced by copolymerization, keep the vacuum degree <800Pa and continue the reaction for 2 hours. Segment copolymer;

[0043] 2) Preparation of polyelectrolyte casting solution

[0044] Weigh 6g of the polybutylene oxide-polycaprolactam copolymer prepared in step 1), add 50g of solvent acetonitrile, stir for 2h under heating at 70°C until completely dissolved, ...

Embodiment 3

[0049] 1) Preparation of polytetrahydrofuran diol-polylaurolactam copolymer

[0050] Add carboxyl-terminated polylaurolactam (molecular weight 8000) into the polymerization kettle, then add 80% polytetrahydrofuran diol (molecular weight 2000) and 0.3% catalyst isopropyl titanate of the total mass of monomers, pump Vacuum-fill with argon for 5 minutes each, cycle four times, heat under the protection of argon until the raw materials are completely melted, and then turn on the stirring paddle. After reacting for 5 hours, vacuumize to remove unreacted monomers and a small amount of water produced by copolymerization, keep the vacuum degree <800Pa and continue the reaction for 2 hours, and discharge when the relative viscosity of the product is 1.62 to obtain polytetrahydrofuran diol-polydodecalide Amide block copolymers;

[0051] 2) Preparation of polyelectrolyte casting solution

[0052] Weigh 4g of the polytetrahydrofuran diol-polylaurolactam copolymer prepared in step 1), ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com