3D chitosan/silicon dioxide composite material and preparation method and application thereof in rhenium adsorption and separation

A technology of silica and composite materials, applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of poor stability of adsorbents, few active sites, and poor adsorption selectivity, etc., to achieve The hydrolysis speed is slow, the preparation process is simple, and the effect of high-efficiency adsorption and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 13

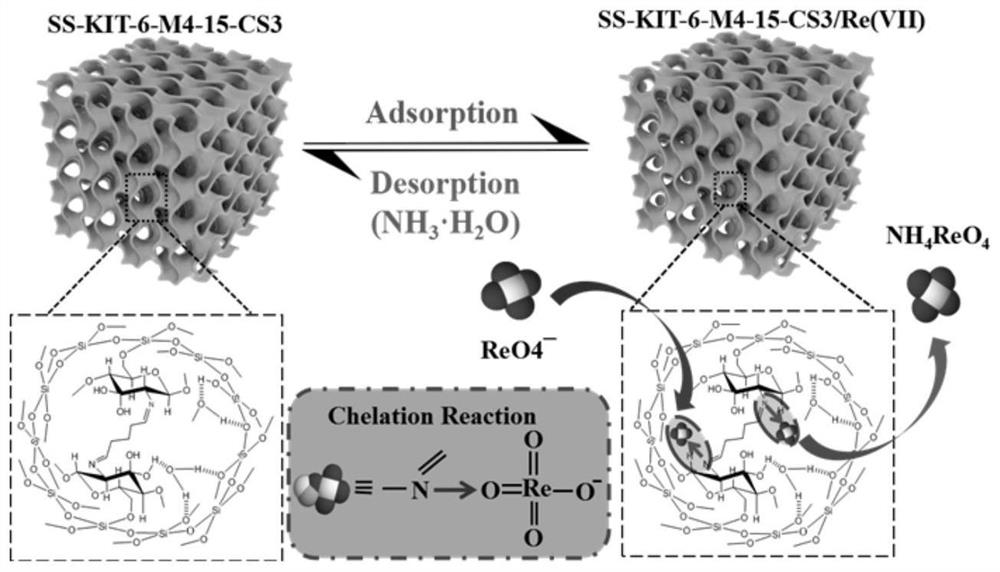

[0044] Embodiment 1 3D chitosan / silica composite material

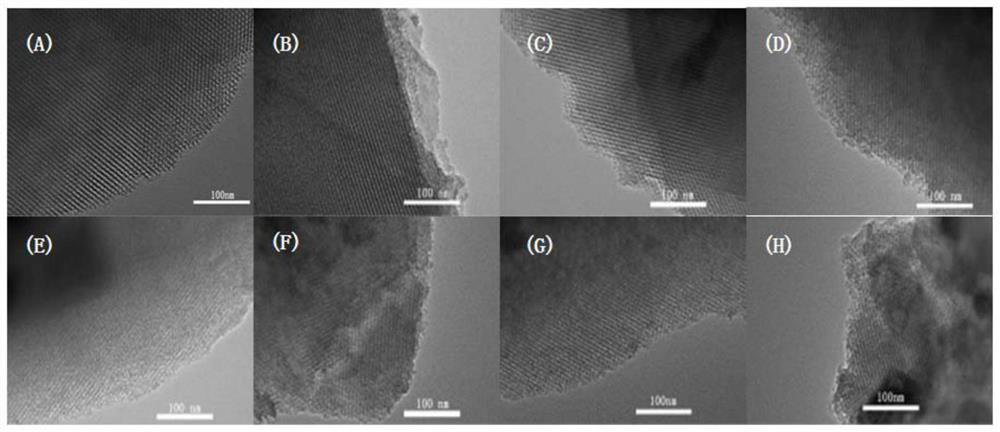

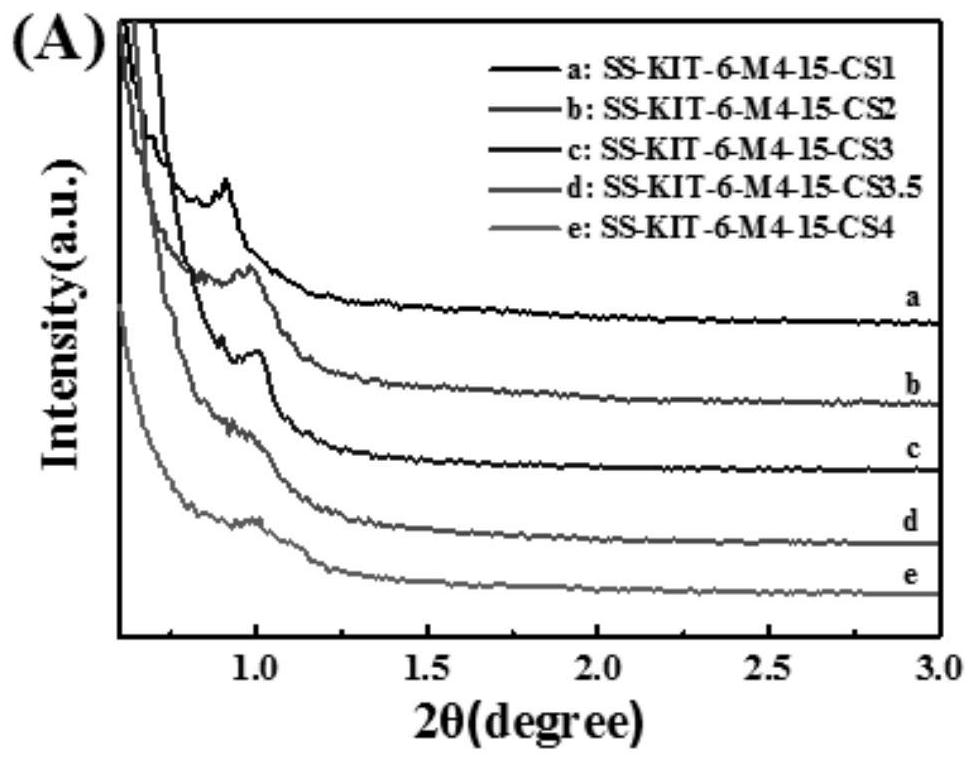

[0045] (1) 3D chitosan / silica composites prepared under different chitosan additions

[0046] 1. 3D chitosan / silica composite material SS-KIT-6-M4-15-CS3

[0047] 1) Dissolve 4.0g of P123 in 120g of deionized water and 20mL of concentrated HCl. After completely dissolving, add 4.0g of n-butanol dropwise to the solution. After mixing and stirring at 308K for 1 hour, slowly drop in 23.46g of 50% aqueous solution of sodium silicate (SS) was stirred for 1.5 hours to obtain a mixed solution.

[0048] 2) mix the mixed solution with chitosan acetic acid solution (3.0g chitosan CS is dissolved in 50mL, in 2% acetic acid) mix, after stirring evenly, add 15mL mass percent concentration and be 25% glutaraldehyde solution (GA ), continue mixing and stirring at 308K for 6h to obtain a mixed system.

[0049] 3) Transfer the mixed system to a microwave reaction tank, and react for 4 hours under the conditions of 400W and 368K usi...

Embodiment 2

[0071] Example 2 Application of 3D Chitosan / Silica Composite Material in Adsorption and Separation of Re(VII) (1) Test of Adsorption Performance of Re(VII) under Different Acidity Conditions

[0072] The method is as follows: Accurately weigh 10 mg of the 3D chitosan / silicon dioxide composite material SS-KIT-6-M4-Y-CSX prepared in Example 1, place them in shaking bottles respectively, add 10 mL of 20 mg·L -1Shake the rhenium solution evenly, put the shaking bottle in a constant temperature shaking box at a speed of 180 rpm, shake at 30°C for 24 hours, filter, and measure the concentration of rhenium ions in the solution before and after adsorption by ultraviolet spectrophotometry. The result is as Figure 5a with Figure 5b shown.

[0073] Depend on Figure 5a It can be seen that as the pH of the solution increases from 1 to 4, the adsorption amount of rhenium by the composite material increases gradually, and then stabilizes above 90% until pH=7. When the addition of chit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com