Preparation and application of copper-cobalt/carbon catalyst derived from metal organic framework material

A catalyst, copper-cobalt technology, applied in the field of preparation of copper-cobalt/carbon catalysts, can solve the problems of plant/algae physiological abnormalities, limited CIP degradation efficiency, genotoxicity and carcinogenicity, etc., to promote highly uniform distribution, prevent aggregation, The effect of promoting transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of synthetic method of CuCo / C catalyst of the present invention, comprises the following steps:

[0036] (1) 6mmol of cobalt nitrate (Co(NO 3 ) 2 .6H 2 O), 6mmol of copper nitrate (Cu(NO 3 ) 2 .3H 2 O) and 12mmol of terephthalic acid (H 2 BDC) was added to a beaker containing 60mL N,N-dimethylformamide (DMF), and stirred at room temperature for 20-30min;

[0037] (2) After the stirring is completed, transfer the mixed solution to a 100mL polytetrafluoroethylene-lined stainless steel autoclave, and add 0.8mL of hydrofluoric acid;

[0038] (3) Transfer the polytetrafluoroethylene-lined stainless steel autoclave with the uniform mixed solution to an oven, heat at 150°C for 72h, and naturally cool to room temperature after the reaction is completed;

[0039] (4) The solid product was washed twice with DMF, ethanol and water, and dried under vacuum at 70 °C for 12 h to collect Cu@Co-MOF.

[0040] (5) Pack the solid collected in (4) into a ceramic boat, put it ...

experiment example 1

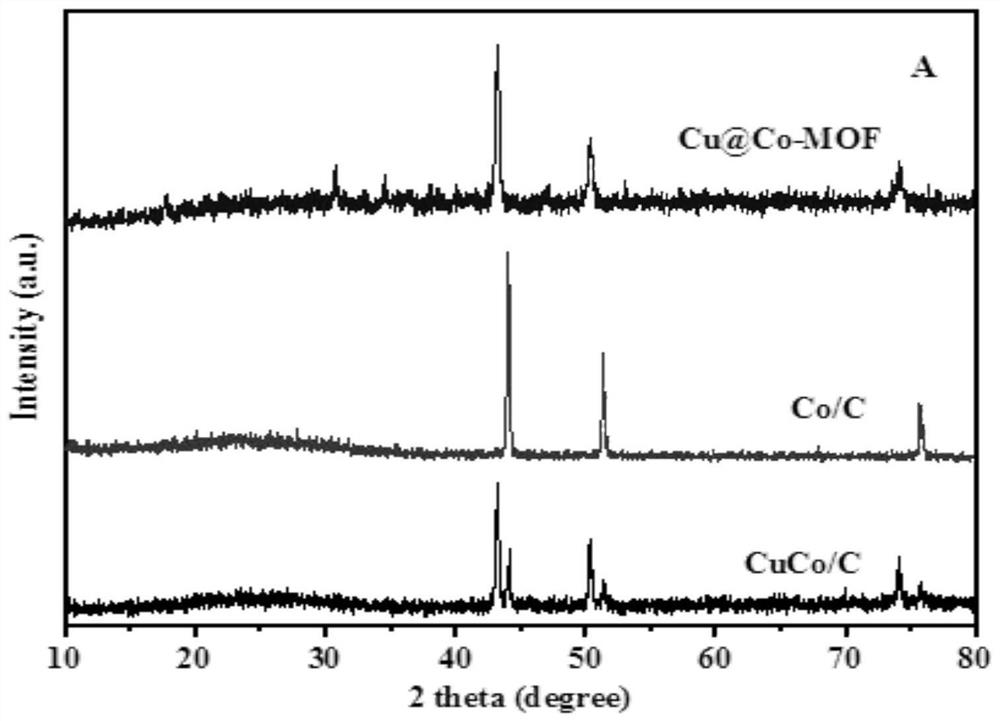

[0049] The Cu@Co-MOF of embodiment 1, CuCo / C and the Co / C of comparative example 1 are carried out XRD analysis, the result is as follows figure 1 shown.

[0050] figure 1 They are the XRD diffraction patterns of Cu@Co-MOF, CuCo / C of Example 1 of the present invention and Co / C of Comparative Example 1, respectively. Such as figure 1 As shown, the indices (200), (220), and (440) corresponding to the diffraction peaks at 43.4°, 50.4°, and 74.1° of the X-ray diffraction pattern of Cu@Co-MOF represent zero-valent copper, indicating that Cu in the solution 2+ Most of it is converted to zero-valent copper. The above results indicated that Cu@Co-MOF was successfully prepared. The XRD patterns of carbonized CuCo / C and Co / C are as follows figure 1 shown. At 26°, there is a weak peak on the (0 02) plane of graphitic carbon, which indicates that the organic ligands of Co-MOF form the carbon matrix through pyrolysis. The diffraction peaks of CuCo / C and Co / C are located at 44.5°, 51...

experiment example 2

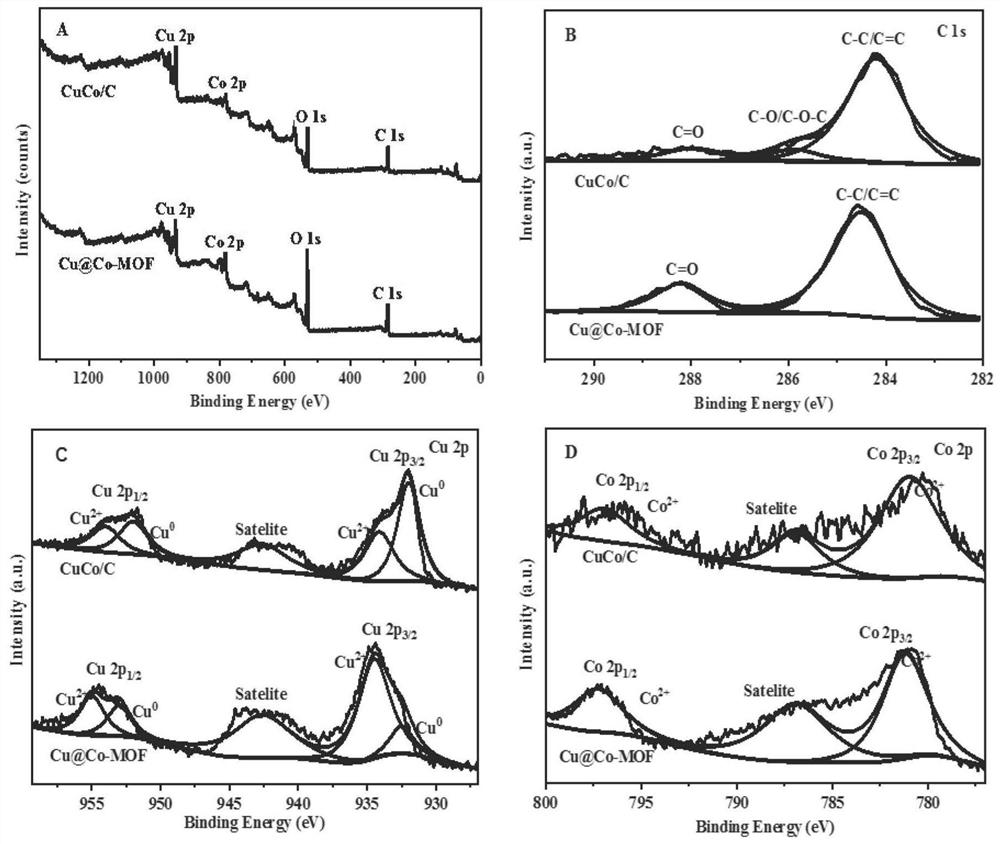

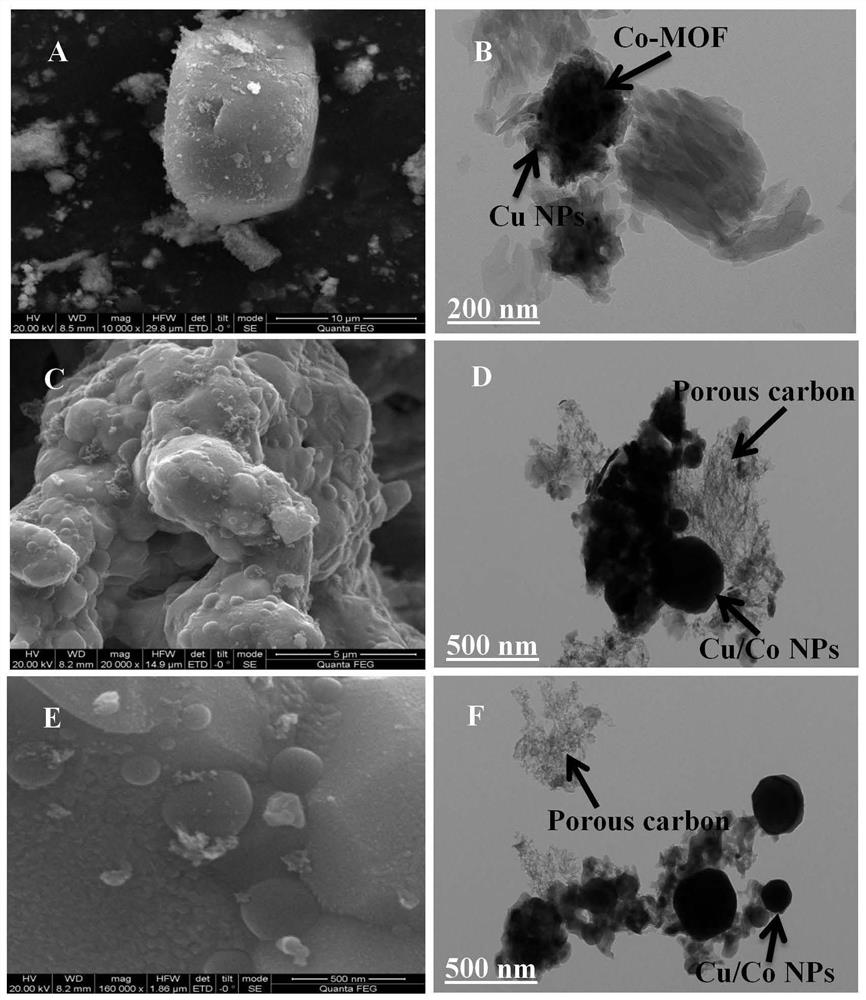

[0052] The Cu@Co-MOF and CuCo / C of Example 1 were analyzed by SEM and TEM. image 3 SEM and TEM electron microscope analysis of Cu@Co-MOF and CuCo / C in Example 1 for the present invention. It can be seen from the figure that SEM shows that Cu@Co-MOF has a spherical structure with a relatively smooth surface. In addition, from the TEM of Cu@Co-MOF, there are small particles dispersed on the surface of Co-MOFs, and these particles on the surface are copper, which indicates that copper was successfully incorporated into Cu@Co-MOF. The SEM image of CuCo / C, obviously, the shape of the precursor is not destroyed, and spherical metal particles are formed, and the surface of the CuCo / C structure is somewhat rough. In addition, the TEM images further confirmed that the nanoparticles have a polyhedral structure, and the Cu / Co nanoparticles are uniformly distributed on the porous carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com