Catalyst for achieving low NOx emission of diesel vehicle and production method thereof

A production method and catalyst technology, which are used in molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation, etc., to achieve the effects of high resistance to hydrothermal aging, promotion of dispersion, and improvement of resistance to water aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

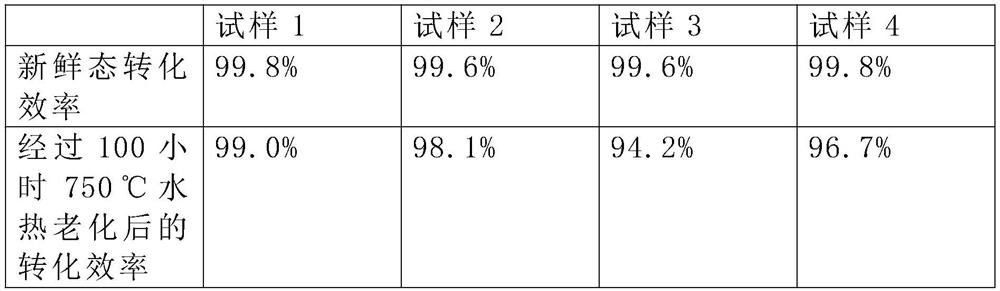

Examples

Embodiment 1

[0033] A method for producing a catalyst for low NOx emissions of diesel vehicles, the steps of which are:

[0034] (1) The metal additive is composed of zirconium nitrate in an amount of 1 wt% of the total weight of the catalyst, barium acetate in an amount of 5 wt% in the total weight of the catalyst and calcium carbonate in an amount of 5 wt% in the total weight of the catalyst.

[0035] Choose a silicon-aluminum ratio of 25-30, an average pore diameter of 10-15nm, and a specific surface area of 820-1100g / m 2 The SAPO molecular sieve was used as a carrier, and the carrier was added to an aqueous solution with a metal additive, dried in a water bath at 80°C after impregnation, dried at 110°C for 12 hours, and then calcined in a muffle furnace at 550°C for 3 hours to obtain a primary catalyst.

[0036] (2) The active component is composed of copper nitrate added in an amount of 2wt% by weight of the catalyst, iron nitrate added in an amount of 2wt% by weight of the catalyst...

Embodiment 2

[0039] A method for producing a catalyst for low NOx emissions of diesel vehicles, the steps of which are:

[0040] (1) The metal additive is composed of zirconium nitrate in an amount of 1 wt% of the total weight of the catalyst, barium acetate in an amount of 3 wt% in the total weight of the catalyst and calcium carbonate in an amount of 7 wt% in the total weight of the catalyst.

[0041] Choose a silicon-aluminum ratio of 50-100, an average pore diameter of 15-25nm, and a specific surface area of 820-1100g / m 2 The SAPO molecular sieve was used as a carrier. The carrier was added to an aqueous solution with metal additives, dried in a water bath at 80°C after impregnation, dried at 120°C for 16 hours, and then calcined in a muffle furnace at 560°C for 4 hours to obtain a primary catalyst.

[0042] (2) The active component is composed of copper sulfate added in an amount of 3wt% of the total weight of the catalyst, iron sulfate added in an amount of 3wt% of the total weight...

Embodiment 3

[0045] A method for producing a catalyst for low NOx emissions of diesel vehicles, the steps of which are:

[0046] (1) The metal additive is composed of zirconium nitrate in an amount of 1 wt% of the total weight of the catalyst, barium acetate in an amount of 3 wt% in the total weight of the catalyst and calcium carbonate in an amount of 7 wt% in the total weight of the catalyst.

[0047] Choose a silicon-aluminum ratio of 20-25, an average pore diameter of 5-10nm, and a specific surface area of 820-1100g / m 2 The SAPO molecular sieve was used as a carrier, and the carrier was added to an aqueous solution with metal additives, dried in a water bath at 80°C after impregnation, then dried at 120°C for 12 hours, and then calcined in a muffle furnace at 560°C for 4 hours to obtain a primary catalyst.

[0048] (2) active component is the copper sulfate of catalyzer gross weight 0.5wt% by addition, the addition is the ferric sulfate of catalyzer gross weight 1wt%, the palladium c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com