Black photovoltaic cell PO backboard processing technology and device

A technology for photovoltaic cells and processing devices, applied in the field of solar cells, can solve the problems of increasing the difficulty of layer-to-layer combination, affecting the cost of photovoltaic electricity prices, and stress concentration between layers and layers, achieving smoothness, good bonding performance, and improved The effect of power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

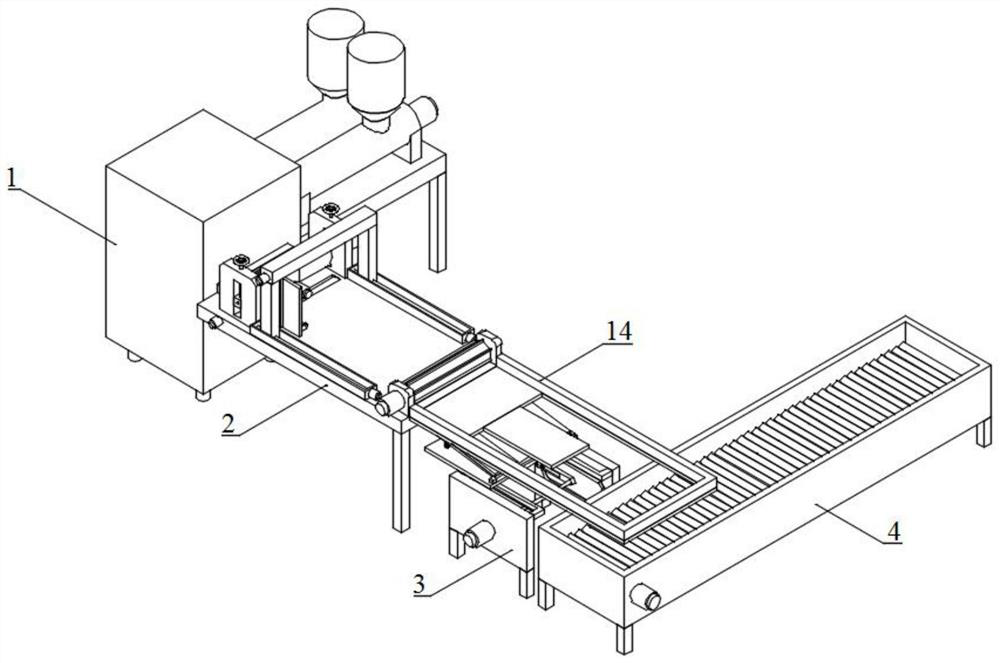

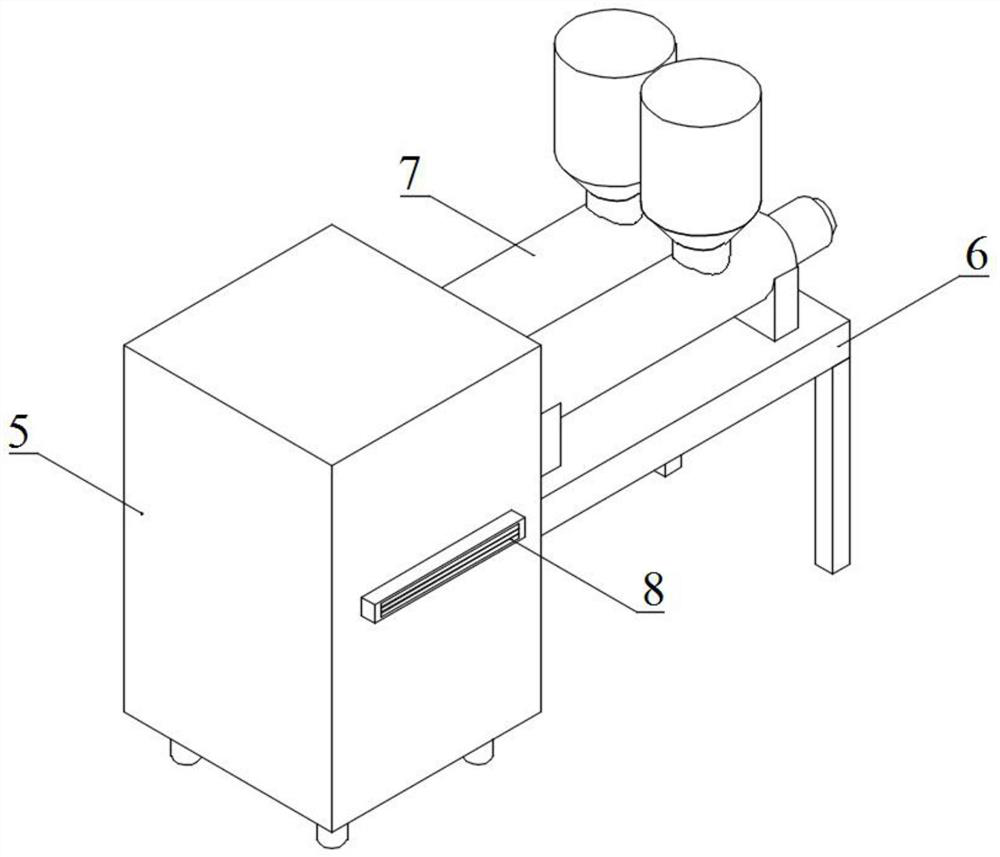

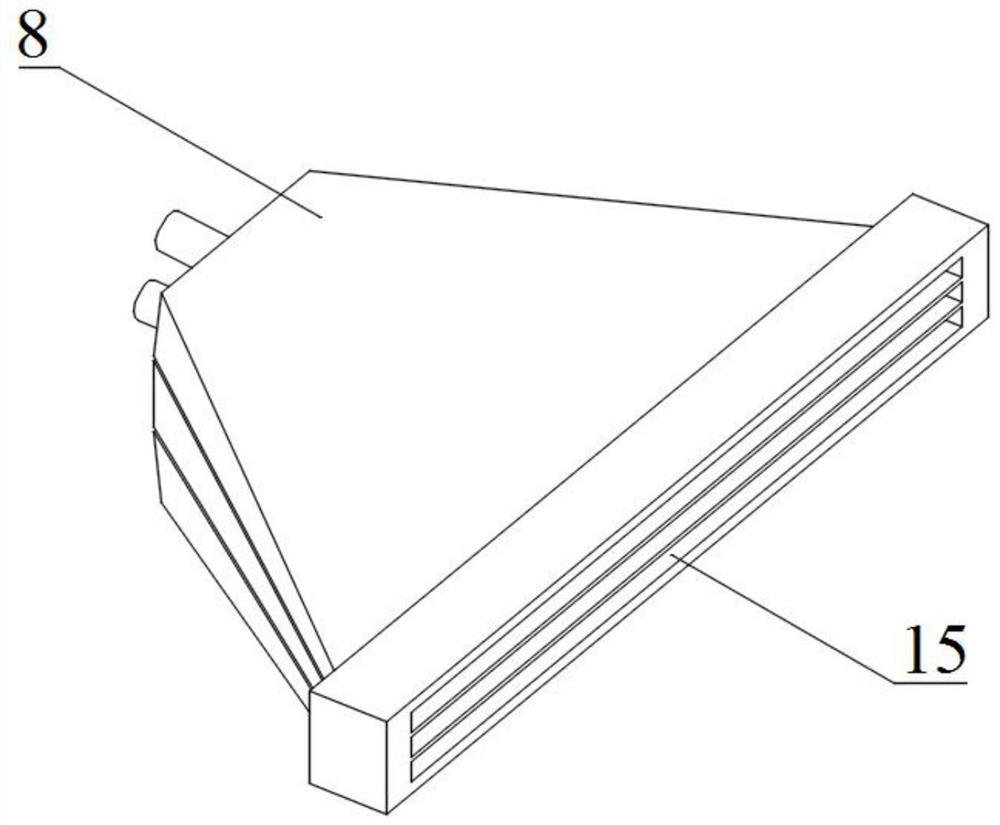

[0051] A kind of processing technology of black photovoltaic battery PO backboard, black photovoltaic battery PO backplane comprises two layers of PO structure layer and one PO bonding layer, and PO bonding layer is arranged between two layers of PO structure layer, and PO structure layer and The PO tie layer is integrally formed through a co-extrusion device, which includes the following steps:

[0052] S1. Mix 50 parts of LDPE, 20 parts of PP, 10 parts of EVA, 0.2 parts of crosslinking agent, 0.1 part of coupling agent, 0.01 part of light stabilizer, and 0.1 part of antioxidant in a high-speed mixer, and then extrude through a single screw. Perform melting reaction in the machine, extrude and granulate to obtain PO structure layer particles;

[0053] S2, will include 70 parts of LDPE, 30 parts of PP, 500 parts of EVA, 0.5 parts of crosslinking agent, 0.2-4 parts of coupling agent, 0.01 part of light stabilizer, 0.1 part of antioxidant, 10 parts of lanthanum oxide, 5 parts of...

Embodiment 2

[0056] A kind of processing technology of black photovoltaic battery PO backboard, black photovoltaic battery PO backplane comprises two layers of PO structure layer and one PO bonding layer, and PO bonding layer is arranged between two layers of PO structure layer, and PO structure layer and The PO tie layer is integrally formed through a co-extrusion device, which includes the following steps:

[0057] S1. Mix 65 parts of LDPE, 40 parts of PP, 12 parts of EVA, 3 parts of crosslinking agent, 2 parts of coupling agent, 0.25 parts of light stabilizer, and 1.2 parts of antioxidant in a high-speed mixer, and then extrude through a single screw. Perform melting reaction in the machine, extrude and granulate to obtain PO structure layer particles;

[0058] S2, will include 80 parts of LDPE, 40 parts of PP, 18 parts of EVA, 2.5 parts of crosslinking agent, 2 parts of coupling agent, 0.25 parts of light stabilizer, 1.5 parts of antioxidant, 13 parts of titanium dioxide, 2 parts of ir...

Embodiment 3

[0061] A kind of processing technology of black photovoltaic battery PO backboard, black photovoltaic battery PO backplane comprises two layers of PO structure layer and one PO bonding layer, and PO bonding layer is arranged between two layers of PO structure layer, and PO structure layer and The PO tie layer is integrally formed through a co-extrusion device, which includes the following steps:

[0062] S1. Mix 80 parts of LDPE, 50 parts of PP, 15 parts of EVA, 5 parts of crosslinking agent, 3 parts of coupling agent, 0.5 parts of light stabilizer, and 2 parts of antioxidant in a high-speed mixer, and then extrude through a single screw. Perform melting reaction in the machine, extrude and granulate to obtain PO structure layer particles;

[0063] S2, will include 90 parts of LDPE, 50 parts of PP, 20 parts of EVA, 5 parts of crosslinking agent, 4 parts of coupling agent, 0.5 parts of light stabilizer, 2 parts of antioxidant, 15 parts of terbium oxide, and 5 parts of copper ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com