High-temperature-resistant star-shaped polymer filtrate reducer, preparation method thereof and water-based drilling fluid

A star-shaped polymer, water-based drilling fluid technology, used in drilling compositions, chemical instruments and methods, etc., can solve the problems of poor high temperature resistance and poor filtration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

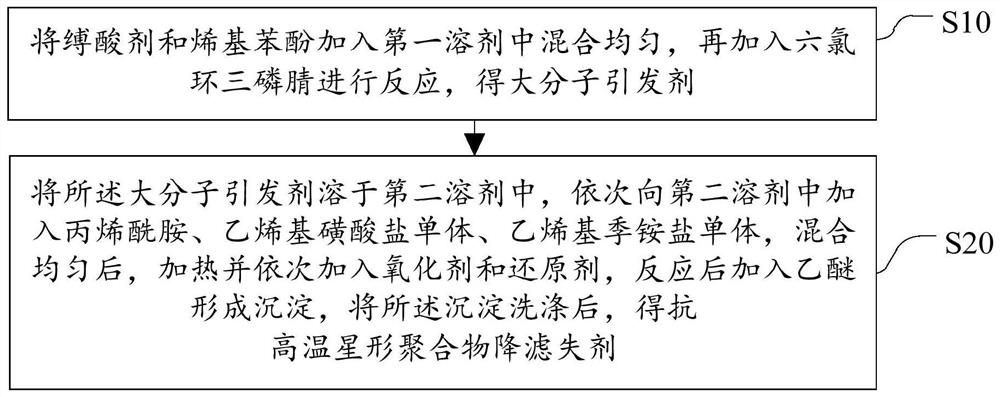

[0061] see figure 1 , the present invention further proposes a method for preparing the above-mentioned high-temperature star-shaped polymer fluid loss control agent, comprising the following steps:

[0062] S10. Add the acid-binding agent and alkenyl phenol into the first solvent and mix evenly, then add hexachlorocyclotriphosphazene for reaction to obtain a macromolecular initiator.

[0063] In this step, a macromolecular initiator is mainly obtained, and a benzene ring and a carbon-carbon double bond are introduced on the surface of the hexachlorocyclotriphosphazene. The whole reaction is a substitution reaction, and the addition of alkenyl phenol is mainly to form free radicals, providing Reactive point, alkenyl phenol reacts with halogen elements on hexachlorocyclotriphosphazene on the one hand, and its carbon-carbon double bond can react with other functional monomers on the other hand, which plays a role in providing reaction sites, chain branches The role of the chain...

Embodiment 1

[0107] (1) In a 500mL three-neck round-bottomed flask equipped with a thermometer, a stirring rod and a nitrogen guide tube, disperse 60.08g of 4-vinylphenol and 0.40g of NaOH into 100mL of tetrahydrofuran and 100mL of N'N-dimethylformaldehyde Nitrogen gas was passed into the mixed solution of amides. Raise the temperature to 80°C, and slowly add 17.38g of hexachlorocyclotriphosphazene dropwise at 10mL / min using a peristaltic pump. After the dropwise addition, maintain the reaction temperature at 80°C, stir at 600rpm for 30h, and distill under reduced pressure after the reaction is completed The solvent was concentrated and precipitated with ether. The obtained precipitate was washed several times with ethyl acetate and distilled water, and the white precipitated macromolecular initiator obtained after vacuum drying at 60° C. for 10 h, the reaction principle is shown in formula (1).

[0108] Formula 1)

[0109] (2) In the 500mL three-neck round-bottomed flask equipped with...

Embodiment 2

[0117] (1) In a 500mL three-necked round-bottomed flask equipped with a thermometer, a stirring rod and a nitrogen guide tube, disperse 57.67g of 3-vinylphenol and 1.39g of anhydrous sodium carbonate into 220mL of N'N-dimethyl In formamide, bubble nitrogen. Raise the temperature to 75°C, and slowly add 13.91g of hexachlorocyclotriphosphazene dropwise at 8mL / min using a peristaltic pump. After the dropwise addition, maintain the reaction temperature at 75°C and stir at 400rpm for 22h. After the reaction is completed, distill under reduced pressure to The solvent was concentrated and precipitated with ether. The obtained precipitate was washed several times with ethyl acetate and distilled water, and the white precipitated macromolecular initiator was obtained after vacuum drying at 50°C for 13 hours. The reaction principle is shown in formula (2).

[0118] Formula (2)

[0119] (2) In the 500mL three-necked round bottom flask that thermometer, stirring bar and nitrogen guide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com