Plastic surface coating structure and preparation method thereof

A surface layer and plastic technology, applied in the field of plastic surface coating structure and its preparation, can solve the problems of poor adhesion between plastic and metal, low plastic absorption and plating ability, inconsistent hydrophilicity, etc., so as to improve the adhesion, The effect of enhanced suction power, reduced corrosion and wear conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

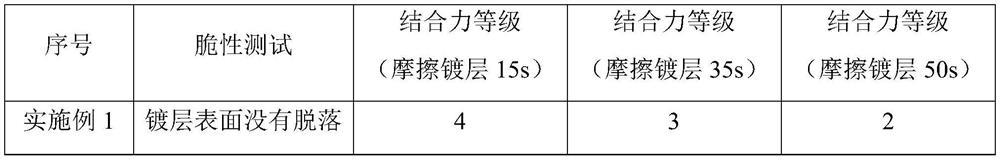

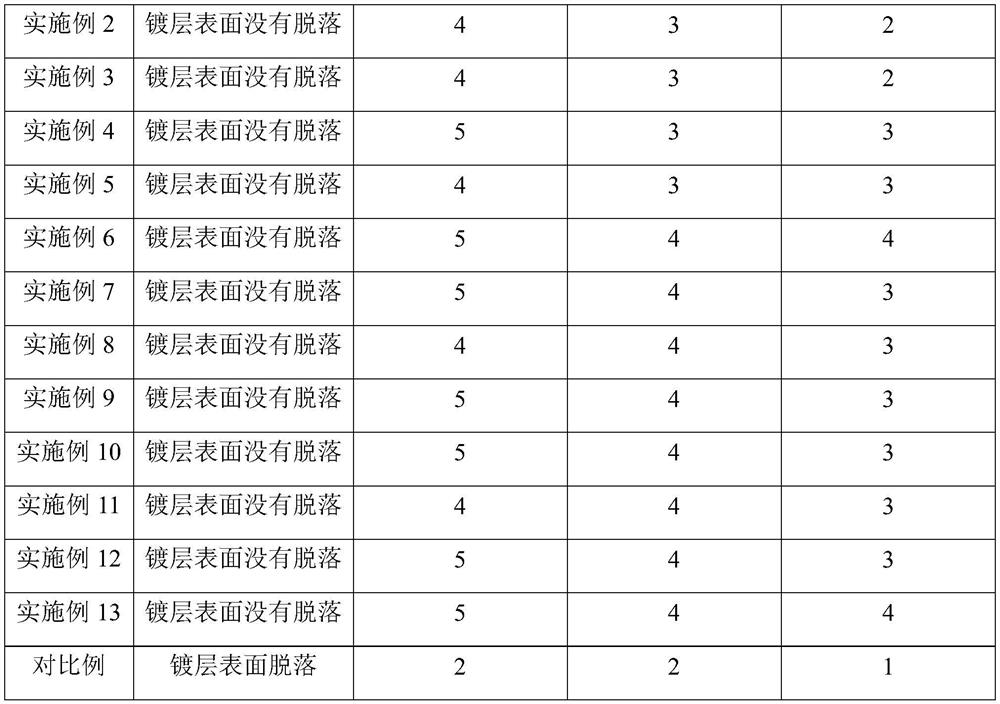

Examples

preparation example Construction

[0036] The preparation method of the plastic surface coating structure of the present application comprises the following steps:

[0037](1) Pretreatment of plastic products: Carry out hydrocarbon vacuum degreasing and drying treatment on plastic products, and then put the dried plastic products into conventional chromium-sulfur mixed acid washing solution for roughening at 70°C for 12 minutes, and then pass through clean water Continue to dry after rinsing, treat with a surface treatment agent, and dry to obtain a plastic product;

[0038] (2) Pre-metallization of plastic products: the plastic product 1 obtained in step (1) is plated with a conductive metal layer to obtain plastic product 2;

[0039] (3) Electroplating nickel on plastic products: electroplating the plastic product 2 obtained in step (2) with nickel to obtain plastic product 3;

[0040] (4) Electroplating functional layer of plastic product: the plastic product 3 obtained in step (3) is plated with a PVD colo...

Embodiment 1

[0070] The plastic surface coating structure of this embodiment, from the plastic surface layer, is successively a conductive metal layer, an electroplated nickel layer, a PVD color layer, and a transparent silicon dioxide film layer, and the plastic product is processed through a surface treatment agent. Composition of raw materials: plasticizer 5kg, sodium lauryl sulfate 5kg, coupling agent 10kg, water 50kg, the plasticizer is composed of acetyl tributyl citrate, cyclohexane-1,2-dicarboxylic acid diisooctyl The ester is composed of a mass ratio of 2:3, and the coupling agent is composed of 3-(2,3-epoxypropoxy)propyltrimethoxysilane and isopropyltris(dioctylpyrophosphate acyloxy)titanate according to The mass ratio is 4:2, the thickness of the conductive metal layer is 3 μm, the thickness of the transparent silicon dioxide film layer is 500 μm, the thickness of the nickel layer is 5 μm, and the thickness of the PVD color layer is 0.5 μm.

[0071] The preparation method of the...

Embodiment 2

[0079] The plastic surface coating structure of this embodiment, from the plastic surface layer, is successively a conductive metal layer, an electroplated nickel layer, a PVD color layer, and a transparent silicon dioxide film layer, and the plastic product is processed through a surface treatment agent. Composition of raw materials: 10kg of plasticizer, 10kg of sodium lauryl sulfate, 15kg of coupling agent, 60kg of water, among which the plasticizer consists of acetyl tributyl citrate, cyclohexane-1,2-dicarboxylic acid diisooctyl The ester is composed of a mass ratio of 2:3, and the coupling agent is composed of 3-(2,3-epoxypropoxy)propyltrimethoxysilane and isopropyltris(dioctylpyrophosphate acyloxy)titanate according to The mass ratio is 4:2, the thickness of the conductive metal layer is 5 μm, the thickness of the transparent silicon dioxide film layer is 1200 μm, the thickness of the nickel layer is 8 μm, and the thickness of the PVD color layer is 1 μm.

[0080] The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com