Electronic industry wastewater treatment method based on short-cut nitrification and denitrification

A short-range nitrification, electronic industry technology, applied in water/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of difficult effluent compliance, secondary pollution, high treatment costs, and reduce energy consumption. , the effect of small footprint and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

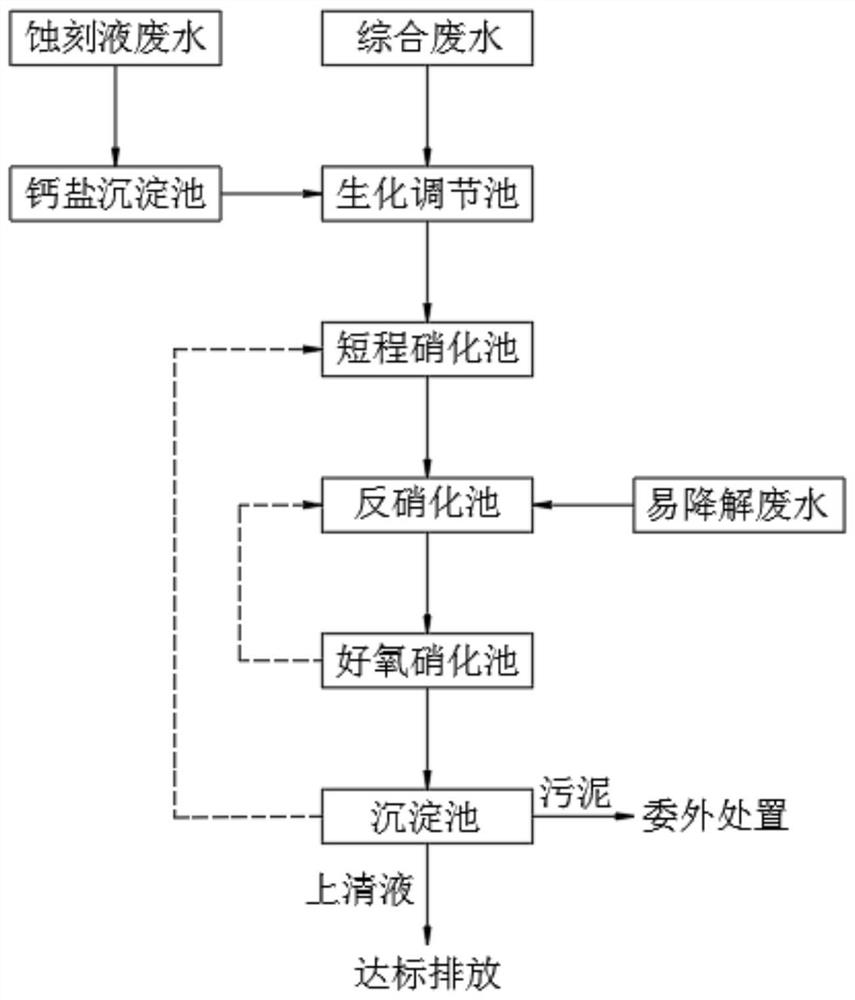

[0025] Embodiment 1: A kind of electronic industry wastewater treatment method based on short-range nitrification and denitrification, such as figure 1 shown, including the following steps:

[0026] S1, transport the etching liquid wastewater to be treated to the calcium salt precipitation tank for pretreatment of fluoride removal, after pretreatment, take the supernatant to measure the fluoride ion concentration in the wastewater (the fluoride ion concentration is in accordance with the "Ion Selective Electrode Method for Determination of Fluoride in Water Quality" ( GB 7484-87) stipulated determination);

[0027] S2. Transport the pretreated waste water and comprehensive waste water after defluorination to the biochemical adjustment pool, and adjust the pH to 7 with hydrochloric acid or sodium hydroxide;

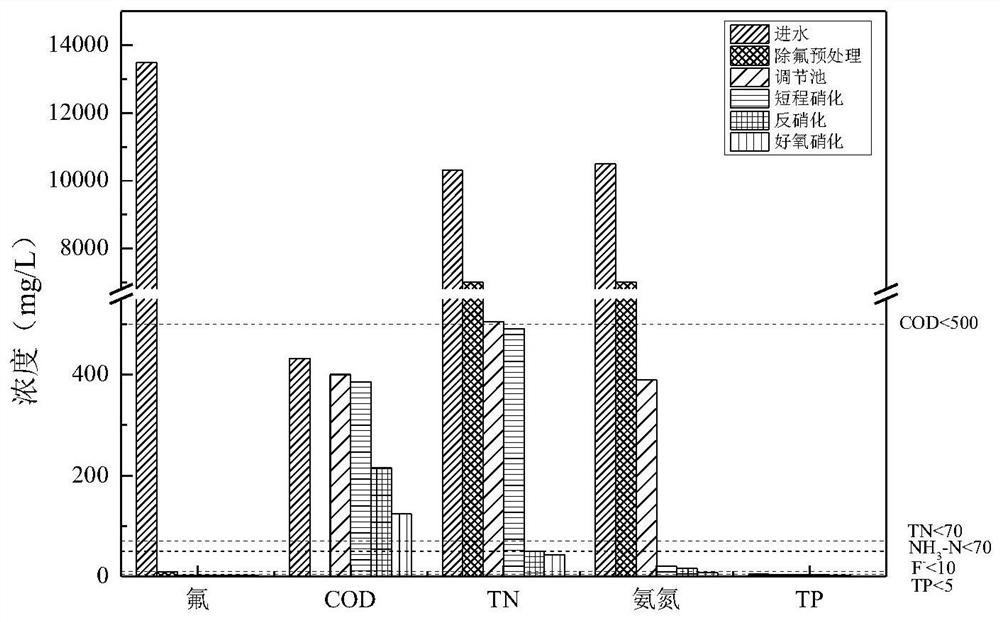

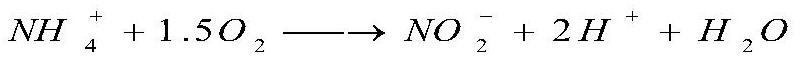

[0028] S3. The wastewater after pH adjustment flows to the short-range nitrification tank for short-range nitrification reaction. The functional flora is ammonia oxidizin...

Embodiment 2

[0047]Embodiment 2: a kind of electronic industry wastewater treatment method based on short-range nitrification and denitrification, such as figure 1 shown, including the following steps:

[0048] S1, transport the etching liquid wastewater to be treated to the calcium salt precipitation tank for pretreatment of fluoride removal, after pretreatment, take the supernatant to measure the fluoride ion concentration in the wastewater (the fluoride ion concentration is in accordance with the "Ion Selective Electrode Method for Determination of Fluoride in Water Quality" ( GB 7484-87) stipulated determination);

[0049] S2. Transport the pretreated waste water and comprehensive waste water after defluorination to the biochemical adjustment tank, and adjust the pH to 8 with hydrochloric acid or sodium hydroxide;

[0050] S3. The wastewater after pH adjustment flows to the short-range nitrification tank for short-range nitrification reaction. The functional flora is ammonia oxidizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com