Diamine monomer, intrinsic type high-dielectric low-loss polyimide as well as preparation method and application of intrinsic high-dielectric low-loss polyimide

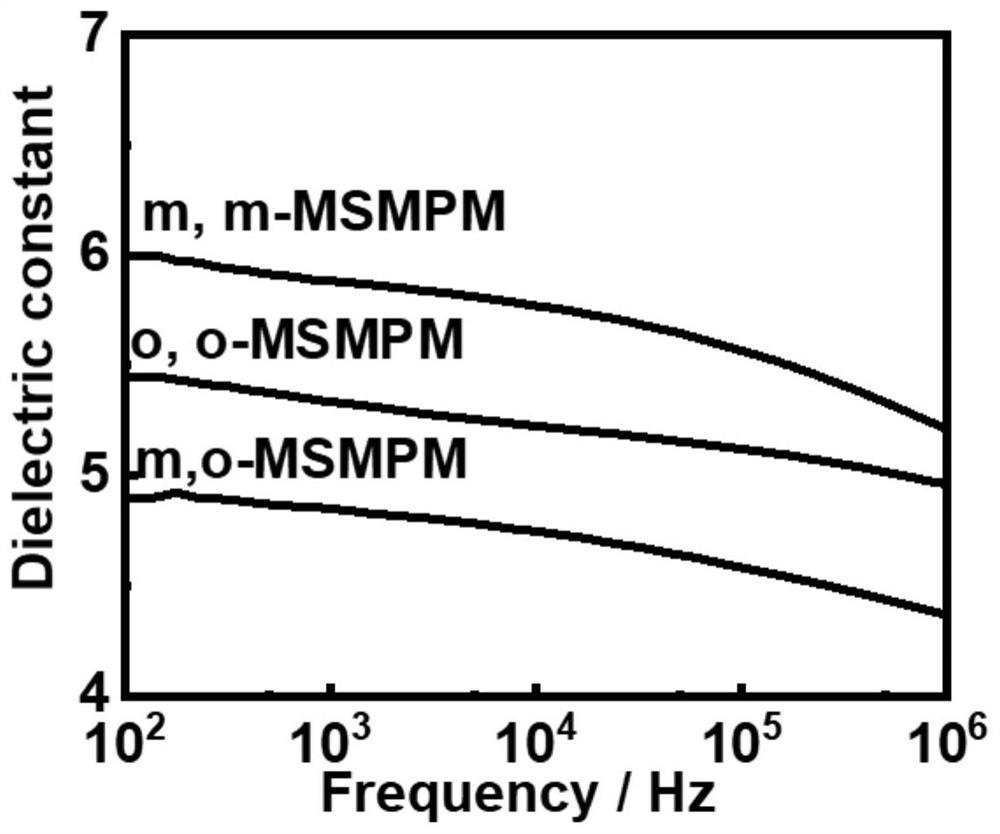

A technology of diamine monomer and polyimide, which is applied in the field of material science, can solve the problems of low dielectric constant and difficult to meet, and achieve the effect of increasing the dielectric constant, increasing the dipole moment, and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

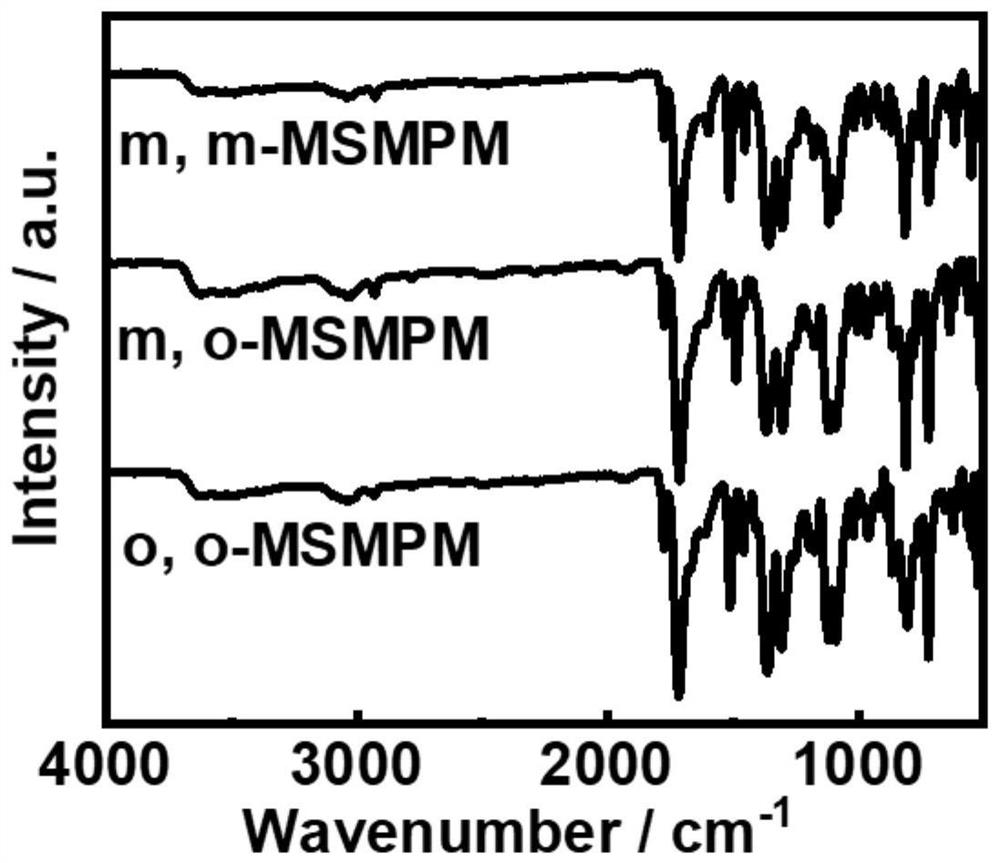

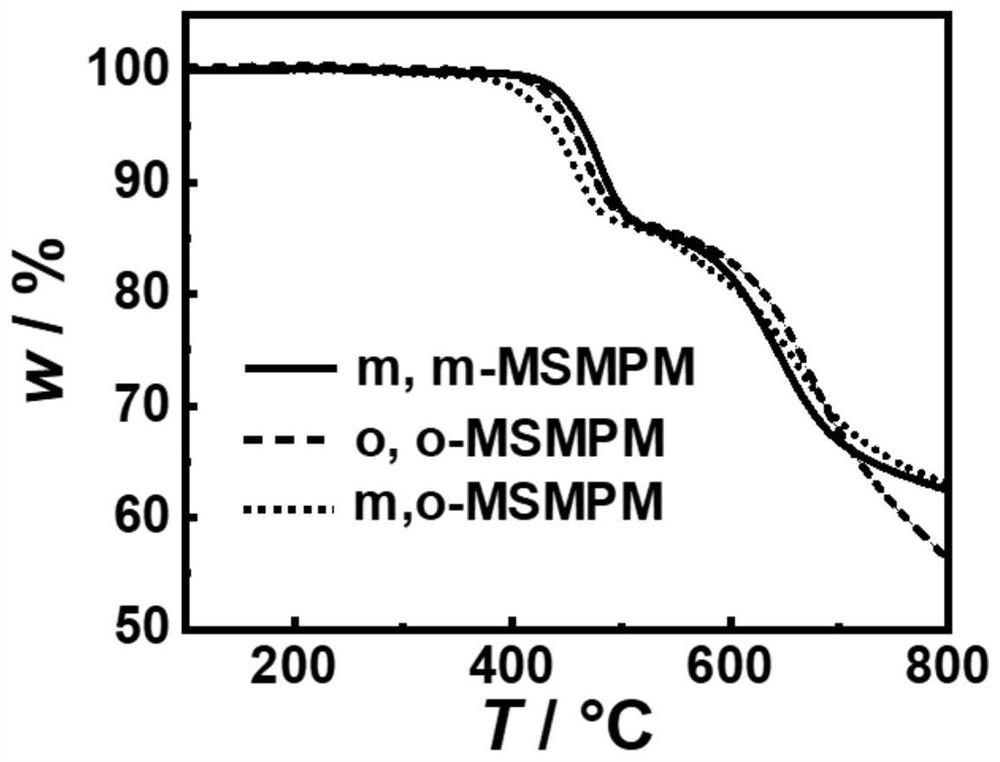

Embodiment 1

[0042] 15g (60.02mmol) 3,5-dibromotoluene, 10.68g (60.02mmol) N-bromosuccinimide, 0.49g azobisisobutyronitrile (3mmol) were dissolved in 180mL acetonitrile, and the temperature was raised under the protection of argon Reflux at 85°C for 3h. The target product 3,5-dibromobenzyl bromide was obtained by petroleum ether column chromatography. 1 H NMR (400MHz, DMSO–d 6 ) δ 7.80 (t, J = 1.7Hz, 1H), 7.72 (d, J = 1.7Hz, 2H), 4.68 (s, 2H).

[0043] 10g (30.41mmol) 3,5-dibromobenzyl bromide, 7.49g (73.32mmol) were added to 75mL DMF, reacted at 60°C for 3 hours, poured into 1000mL saturated aqueous sodium chloride solution, a white solid precipitated, dried The target product 1,3-dibromo-5(methylsulfonylmethyl)benzene was obtained. 1 H NMR (400MHz, DMSO–d 6 ) δ 7.90 (t, J = 1.8Hz, 1H), 7.66 (d, J = 1.8Hz, 2H), 4.55 (s, 2H), 2.96 (s, 3H).

[0044] 4g (12.19mmol) 1,3-dibromo-5 (methylsulfonylmethyl) benzene, 5.08g (36.58mmol, 2.4eq) p-aminophenyl borate hydrochloride, 33mL 2M K 2 CO ...

Embodiment 2

[0052] 15g (60.02mmol) 2,5-dibromotoluene, 10.68g (60.02mmol) N-bromosuccinimide, 0.49g azobisisobutyronitrile (3mmol) were dissolved in 180mL acetonitrile, and the temperature was raised under the protection of argon Reflux at 85°C for 3h. The target product 2,5-dibromobenzyl bromide was obtained by petroleum ether column chromatography.

[0053] 10g (30.41mmol) 2,5-dibromobenzyl bromide, 7.49g (73.32mmol) were added to 75mL DMF, reacted at 60°C for 3 hours, poured into 1000mL saturated aqueous sodium chloride solution, a white solid was precipitated, after drying The target product 1,4-dibromo-2-(methylsulfonylmethyl)benzene was obtained.

[0054] 4g (12.19mmol) 1,4-dibromo-2-(methylsulfonylmethyl)benzene, 5.08g (36.58mmol, 2.4eq) p-aminophenyl borate hydrochloride, 33mL 2M K 2 CO 3 Solution, catalytic amount Pd(PPh 3 ) 4 Added to 65 mL THF. Reaction at 70°C for 48h. The target product 2'-(methylsulfonylmethyl)-(1,1':4',1"-triphenyl)-4,4"-diamine (m,o-MSMDA) was obtai...

Embodiment 3

[0062] 15g (60.02mmol) 2,6-dibromotoluene, 10.68g (60.02mmol) N-bromosuccinimide, 0.49g azobisisobutyronitrile (3mmol) were dissolved in 180mL acetonitrile, and the temperature was raised under the protection of argon Reflux at 85°C for 3h. The target product 2,5-dibromobenzyl bromide was obtained by petroleum ether column chromatography.

[0063] 10g (30.41mmol) 2,6-dibromobenzyl bromide, 7.49g (73.32mmol) were added to 75mL DMF, reacted at 60°C for 3 hours, poured into 1000mL saturated aqueous sodium chloride solution, a white solid precipitated, dried The target product 1,3-dibromo-2-(methylsulfonylmethyl)benzene was obtained.

[0064] 4g (12.19mmol) 1,3-dibromo-2-(methylsulfonylmethyl)benzene, 5.08g (36.58mmol, 2.4eq) p-aminophenyl borate hydrochloride, 33mL 2M K 2 CO 3 Solution, catalytic amount Pd(PPh 3 ) 4 Added to 65 mL THF. Reaction at 70°C for 48h. The target product 2'-(methylsulfonylmethyl)-(1,1':3',1"-triphenyl)-4,4"-diamine (o,o-MSMDA) was obtained after c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com