Method for extracting euphausia superba oil based on low-temperature continuous phase change technology

A technology of low-temperature continuous phase change and Antarctic krill oil, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc. It can solve the problems of large reagent volume, weakened water holding capacity, solvent residue, etc., and achieve protection quality, The effect of improving the extraction rate and avoiding the generation of harmful components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

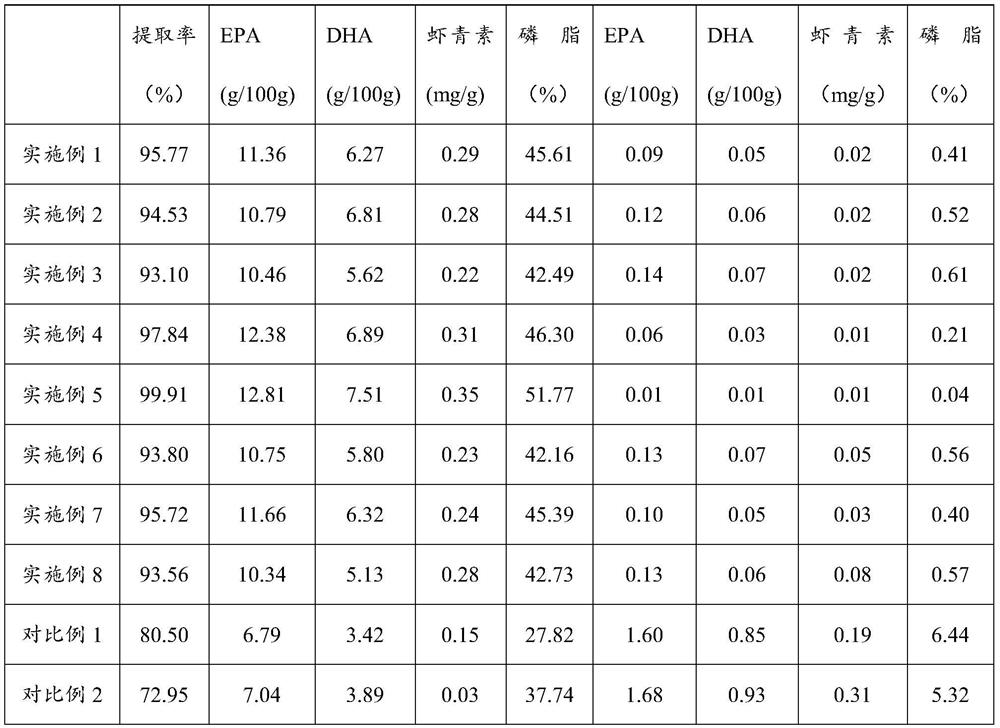

Examples

Embodiment 1

[0025] A method for extracting Antarctic krill oil based on low-temperature continuous phase change technology, comprising the following steps:

[0026] S1 Antarctic krill meal raw materials are dried using a blast dryer to control the temperature at about 30°C, and the moisture content is controlled to be ≤10%.

[0027] S2 Weigh 1.0 kg of Antarctic krill powder processed in step S1, put it into the extraction kettle of the continuous phase change extraction device, add 3 L of absolute ethanol and soak for 3 hours.

[0028] S3 Compress the extraction kettle described in step S2 at an extraction temperature of 40°C and an extraction pressure of 0.45Mpa, compress n-butane into a liquid, flow through the extraction kettle at a flow rate of 60L / h, and continuously extract for 10min to extract krill After the oil enters the analysis kettle, the analysis temperature is 60°C, and the analysis pressure is 0.25Mpa; through heating and decompression, the n-butane phase changes into a ga...

Embodiment 2

[0031] A method for extracting Antarctic krill oil based on low-temperature continuous phase change technology, comprising the following steps:

[0032] S1 Antarctic krill meal raw materials are dried using a blast dryer to control the temperature at about 30°C, and the moisture content is controlled to be ≤10%.

[0033] S2 Weigh 1.0 kg of Antarctic krill powder processed in step S1, put it into the extraction kettle of the continuous phase change extraction device, add 3 L of absolute ethanol and soak for 3 hours.

[0034] S3 Compress the n-butane into a liquid in the extraction kettle described in step S2 at an extraction temperature of 40°C and an extraction pressure of 0.55Mpa, and flow through the extraction kettle at a flow rate of 60L / h for continuous extraction for 15min to extract krill After the oil enters the analysis kettle, the analysis temperature is 60°C, and the analysis pressure is 0.25Mpa; through heating and decompression, the n-butane phase changes into a g...

Embodiment 3

[0037] A method for extracting Antarctic krill oil based on low-temperature continuous phase change technology, comprising the following steps:

[0038] S1 Antarctic krill meal raw materials are dried using a blast dryer to control the temperature at about 30°C, and the moisture content is controlled to be ≤10%.

[0039] S2 Weigh 1.0 kg of Antarctic krill powder processed in step S1, put it into the extraction kettle of the continuous phase change extraction device, add 3 L of absolute ethanol and soak for 3 hours.

[0040] S3 Compress the extraction kettle described in step S2 under the conditions of extraction temperature 40°C and extraction pressure 0.65Mpa, compress n-butane into a liquid, flow through the extraction kettle at a flow rate of 60L / h, and extract krill continuously for 20min. After the oil enters the analysis kettle, the analysis temperature is 60°C, and the analysis pressure is 0.25Mpa; through heating and decompression, the n-butane phase changes into a gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com