RO (reverse osmosis) membrane scale inhibitor for industrial wastewater treatment and use method of RO membrane scale inhibitor

A technology of reverse osmosis membrane and industrial wastewater, applied in the field of water treatment, can solve the problems of easy passivation of active groups, affecting the dosing of scale inhibitors, poor anti-flocculation effect, etc. release effect, high active complexing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

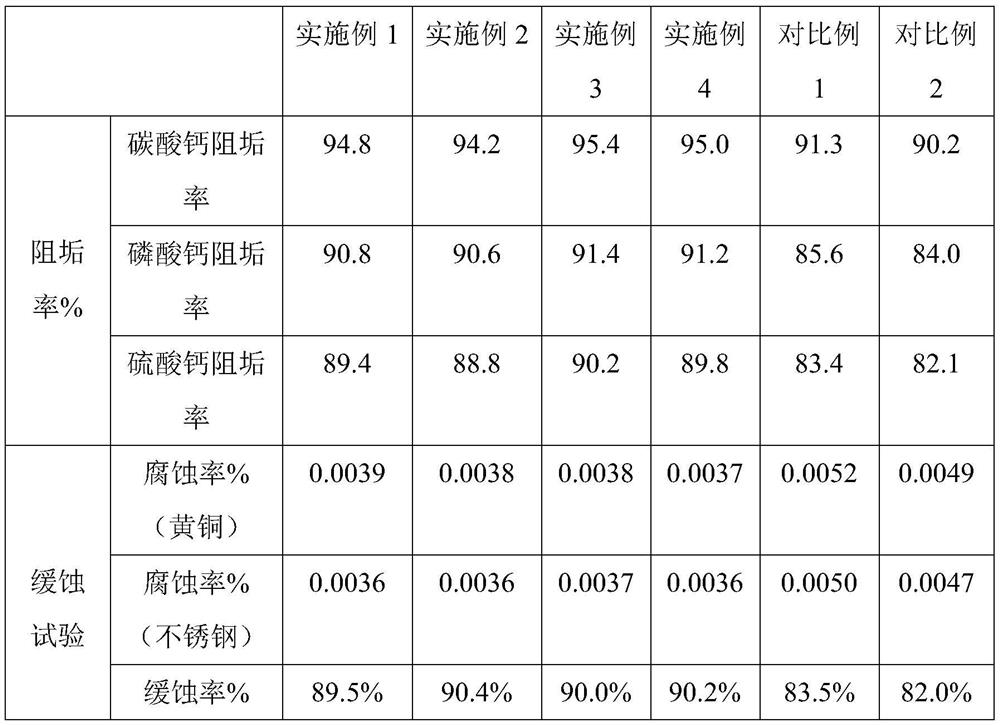

Examples

Embodiment 1

[0026] An RO reverse osmosis membrane scale inhibitor for industrial wastewater treatment, comprising the following raw material components: 15 parts of hydroxyethylidene diphosphonic acid, 8 parts of hydrolyzed polymaleic anhydride, 6 parts of soluble zinc salt zinc gluconate, lignosulfonic acid 20 parts of sodium, 40 parts of activated humic acid, 8 parts of propylene glycol alginate, 8 parts of surfactant dodecyltrimethylammonium bromide;

[0027] The preparation method of the activated humic acid is: adding a 40% sodium hydroxide aqueous solution to the humic acid, adjusting the pH to about 9.0, adjusting the solid-liquid ratio at 0.5:1, and under the condition of stirring, the activation time 35 minutes, the activation temperature is 80°C, centrifuged, filtered and dried, washed with water until neutral, centrifuged and dried to obtain activated humic acid.

[0028] The usage method of described antiscalant, the usage amount of described antiscalant is at 5.0mg / L, and the...

Embodiment 2

[0032] RO reverse osmosis membrane scale inhibitor, including the following raw materials: 15 parts of hydroxyethylidene diphosphonic acid, 8 parts of hydrolyzed polymaleic anhydride, 6 parts of soluble zinc salt zinc gluconate, 20 parts of sodium lignosulfonate, activated humic acid 40 parts of acid, 8 parts of propylene glycol alginate, 8 parts of surfactant dodecyl dimethyl phenyl phosphorus bromide;

[0033] The rest are the same as in Example 1.

Embodiment 3

[0035] RO reverse osmosis membrane scale inhibitor, including the following raw material components: 15 parts of hexamethylenediamine tetramethylene phosphonic acid, 8 parts of hydrolyzed polymaleic anhydride, 6 parts of soluble zinc salt zinc gluconate, 20 parts of sodium lignosulfonate, 40 parts of activated humic acid, 8 parts of propylene glycol alginate, 8 parts of surfactant dodecyl dimethyl phenyl phosphorus bromide;

[0036] The rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com