Preparation method of polyether

A technology of polyether and ring-opening polymerization, which is applied in the field of polymer synthesis, can solve problems such as complex processes, and achieve the effects of simple post-processing, saving cost and time, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The raw materials in the preparation method of the polyether that the embodiment of the present invention and comparative examples provide are as follows:

[0050] 1,2-Butylene oxide: purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., CAS No.: 106-88-7, used after refluxing in calcium hydride for 8 hours;

[0051] Tetrahydrofuran: purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., CAS number: 106-88-7, ultra-dry solvent;

[0052] 1,4-Butanediol: purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., CAS No.: 110-63-4;

[0053] Scandium trifluoromethanesulfonate: purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., CAS number: 144026-79-9;

[0054] Yttrium trifluoromethanesulfonate: purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., CAS number: 52093-30-8;

[0055] Lanthanum trifluoromethanesulfonate: purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., CAS number: 52093-26-2;

[0056] C...

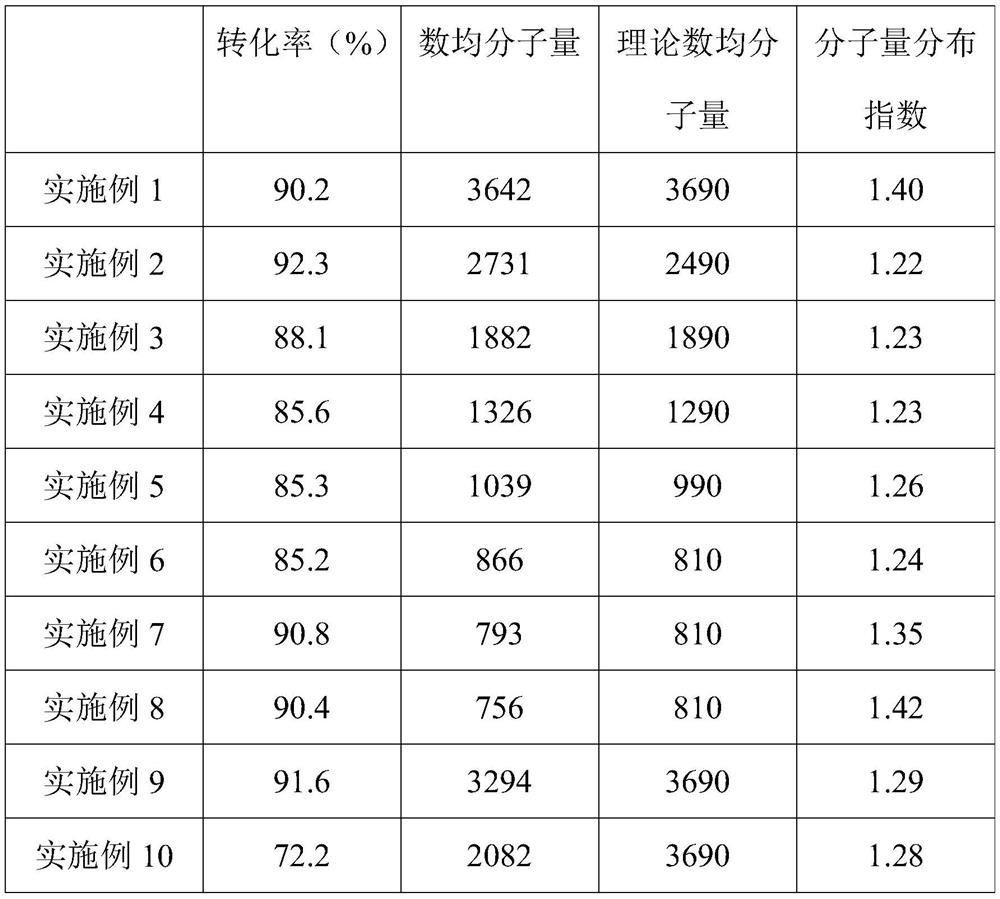

Embodiment 1

[0061] The present embodiment provides a kind of preparation method of polyether, concrete steps are as follows:

[0062] Weigh scandium trifluoromethanesulfonate (295mg, 0.60mmol) and add it to a dry three-necked round-bottomed flask. After three vacuum-nitrogen cycles, add 1,4-butanediol (900mg, 10mmol) and tetrahydrofuran under nitrogen protection. (18000mg, 250mmol), after stirring and mixing evenly, at 25°C, add 1,2-epoxybutane (18000mg, 250mmol) dropwise at a rate of 0.05mL / min through a convection pump, and immediately add 3mL water, continue to stir for 1 h, transfer the reaction solution to a 500 mL separating funnel, add 3×50 mL of water for extraction three times, collect the oil phase, and distill off the water under reduced pressure to obtain the polyether (PBT-1).

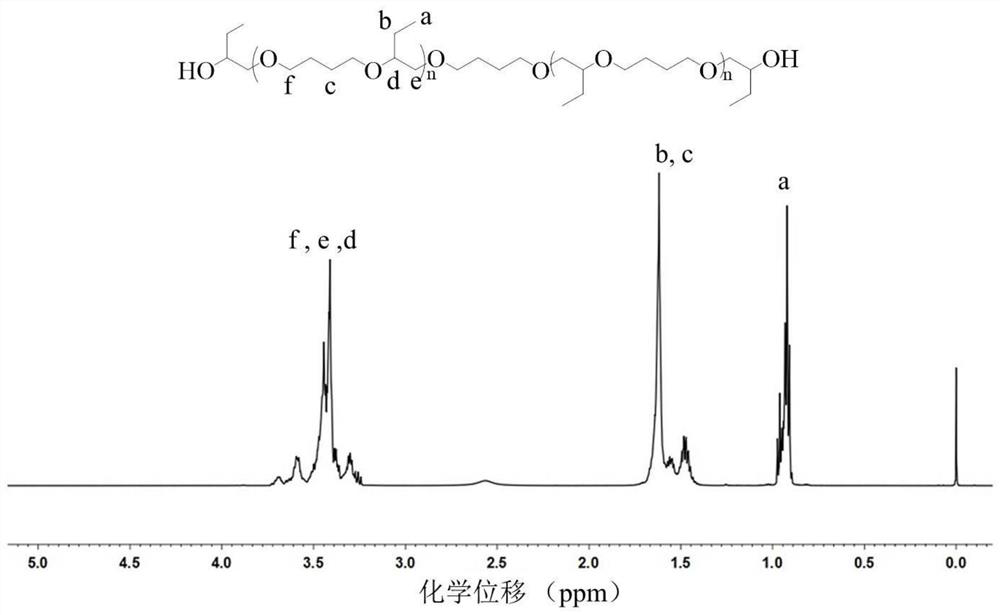

[0063] The proton nuclear magnetic resonance spectrum figure of described polyether (PBT-1) is as figure 1 As shown, the test instrument is a 600MHz nuclear magnetic resonance spectrometer, and the d...

Embodiment 2

[0066] The present embodiment provides a kind of preparation method of polyether, concrete steps are as follows:

[0067] Weigh scandium trifluoromethanesulfonate (295mg, 0.60mmol) and add it to a dry three-necked round-bottomed flask. After three vacuum-nitrogen cycles, add 1,4-butanediol (1350mg, 15mmol) and tetrahydrofuran under nitrogen protection. (18000mg, 250mmol), after stirring and mixing evenly, at 25°C, add 1,2-epoxybutane (18000mg, 250mmol) dropwise at a rate of 0.05mL / min through a convection pump, and immediately add 3mL water, continue stirring for 1 h, transfer the reaction solution to a 500 mL separatory funnel, add 3×50 mL of water for extraction three times, collect the oil phase, and distill off the water under reduced pressure to obtain the polyether (PBT-2).

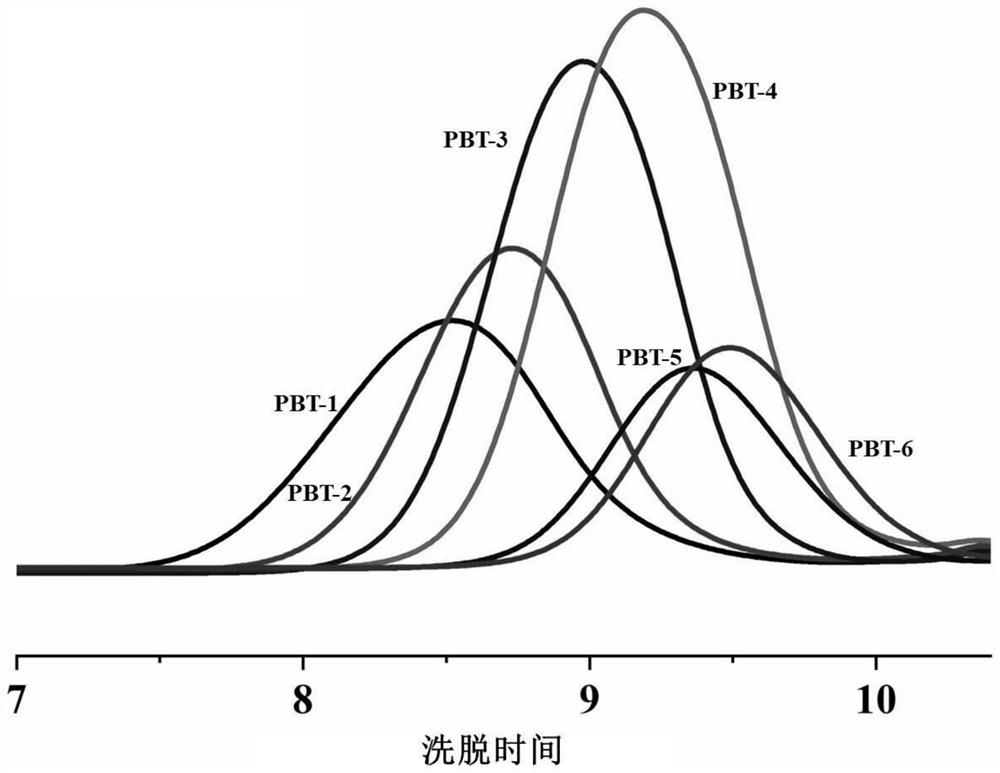

[0068] The gel permeation chromatogram of described polyether (PBT-2) is as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com