Preparation method and application of bacillus subtilis for feed

A Bacillus subtilis and feeding technology, which is applied in the field of microbial feed additives and preparation, can solve the problems of low utilization rate of yellow pulp water, environmental pollution, waste of resources, etc. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

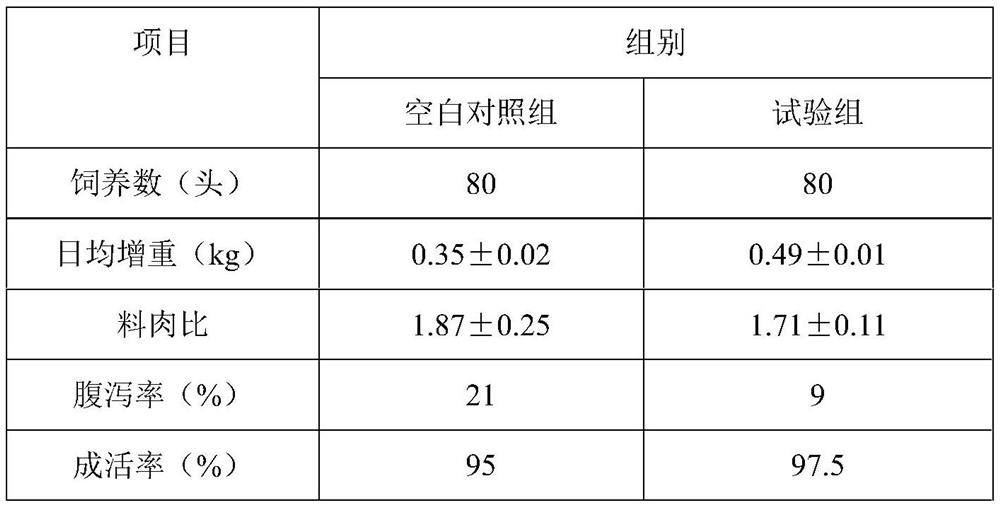

Image

Examples

Embodiment 1

[0027] The inoculation ratios of the seed liquid were respectively inserted into the fermentation medium, and the fermentation experiments were carried out. The inoculation ratios were 1%, 3%, 5%, 7%, and 9%, respectively. 20h, the fermentation medium is bean dregs 21g / L, corn flour 25g / L, ammonium sulfate 6.5g / L, molasses 10g / L, sodium chloride 3g / L, magnesium sulfate 0.25g / L, yeast powder 12g / L, Peptone 3g / L, calcium chloride 0.1g / L, disodium hydrogen phosphate 0.2g / L, sodium dihydrogen phosphate 0.2g / L, yellow syrup water instead of water as liquid supplement, mix and stir, sterilize at 110 °C. The number of colonies of the bacterial agent was determined, and the crude protein results were shown in Table 1.

[0028] Table 1 Effects of different bacterial species ratios on the number of viable bacteria in fermentation

[0029] Seed liquid ratio Total colony count, cfu / mL Crude protein, % 2% 1.24×10 8

Embodiment 2

[0031] The inoculum amount of 5% (V / V) will be inserted into the fermentation medium, the fermentation temperature is 25 ℃, 30 ℃, 32 ℃, 35 ℃, 37 ℃, 42 ℃, the inoculation amount is 6%, and the cultivation time is 16~ 20h, the fermentation medium is bean dregs 25g / L, corn flour 25g / L, ammonium sulfate 8g / L, molasses 6g / L, sodium chloride 3g / L, magnesium sulfate 0.15g / L, yeast powder 20g / L, peptone 5g / L, calcium chloride 0.5g / L, disodium hydrogen phosphate 0.2g / L, sodium dihydrogen phosphate 0.2g / L, yellow slurry water instead of water as liquid supplement, mix and stir, sterilize at 110°C. , determine the total number of colonies, cfu / mL, crude protein, %, the results are shown in Table 2. Therefore, the optimal fermentation temperature is 37°C.

[0032] Table 2 Effects of different fermentation temperatures on various physical and chemical indicators of fermentation products

[0033] Fermentation temperature, °C Total colony count, cfu / mL Crude protein, % 25...

Embodiment 3

[0035] The present invention investigates a preparation method and application of a forage Bacillus subtilis, and compares the following three culture media: (1) culture medium A: bean dregs 25g / L, corn meal 25g / L, ammonium sulfate 8g / L, molasses 8g / L, sodium chloride 3g / L, magnesium sulfate 0.3g / L, yeast powder 20g / L, peptone 4g / L, calcium chloride 0.5g / L, disodium hydrogen phosphate 0.3g / L, Sodium dihydrogen phosphate 0.3g / L, yellow slurry water instead of water as liquid supplement; (2) Medium B: glucose 20g / L, corn flour 25g / L, ammonium sulfate 8g / L, sodium chloride 3g / L, sulfuric acid Magnesium 0.3g / L, yeast powder 20g / L, peptone 3g / L, calcium chloride 0.6g / L, disodium hydrogen phosphate 0.2g / L, sodium dihydrogen phosphate 0.2g / L, water as liquid supplement,;( 3) Medium C: glucose 30g / L, corn flour 25g / L, ammonium sulfate 10g / L, molasses 8g / L, sodium chloride 3g / L, magnesium sulfate 0.4g / L, yeast powder 20g / L, peptone 5g / L, calcium chloride 0.6g / L, disodium hydrogen ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com