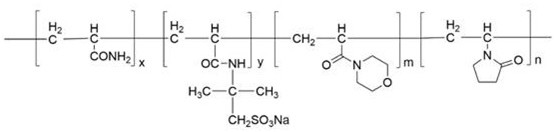

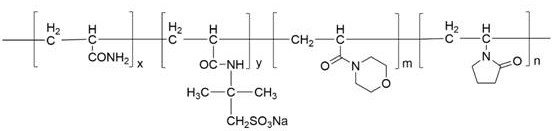

Temperature-resistant and salt-resistant multi-component polymerization thickening agent and preparation method thereof

A temperature-resistant, salt-resistant, thickener technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of reduced strength of polymer skeleton structure, decreased performance of conventional oil displacement polymers, and unstable hydration capacity and other problems, to achieve the effect of improving aging stability, facilitating large-scale industrial production, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

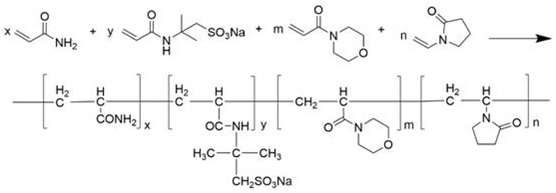

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a temperature-resistant and salt-resistant multi-polymerization thickener, the steps are as follows:

[0029] S1. Weigh the raw material components according to the following mass percentages: 180 parts of deionized water, 80 parts of acrylamide, 20 parts of sodium 2-acrylamido-2-methylpropylsulfonate, 10 parts of vinylpyrrolidone, and 10 parts of propylene Add morpholine into the reaction kettle, heat to 70°C, stir and mix evenly at constant temperature;

[0030] S2. Introduce nitrogen into the reactor for 30 min to carry out oxygen removal operation, and add 0.1 part of ammonium persulfate, 0.1 part of sodium sulfite and 0.1 part of azobisisobutylimidazoline hydrochloride to the mixed material in step S1, drop Added for 30 min; after the dropwise addition was completed, stirred and reacted for 6 h;

[0031] S3. After the reaction is completed, after solvent precipitation, cooling and solidification, natural drying, and then shearing and pulver...

Embodiment 2

[0033] A preparation method of a temperature-resistant and salt-resistant multi-polymerization thickener, the steps are as follows:

[0034] S1. Weigh the raw material components according to the following mass percentages: 260 parts of deionized water, 80 parts of acrylamide, 20 parts of 2-acrylamido-2-methylpropyl sodium sulfonate, 6 parts of vinylpyrrolidone, 6 parts of propylene Add morpholine into the reaction kettle, heat to 60°C, stir and mix evenly at constant temperature;

[0035] S2. Introduce nitrogen gas into the reactor for 30 minutes to carry out oxygen removal operation, and add 0.067 parts of ammonium persulfate, 0.033 parts of sodium bisulfite and 0.05 parts of azobisisobutylimidazoline hydrochloride to the mixed material in step S1 Salt, added dropwise for 30 min; after the dropwise addition, stirred and reacted for 6 h;

[0036] S3. After the reaction was completed, the solvent was settled, cooled and solidified, dried naturally, and then sheared and pulver...

Embodiment 3

[0038] A preparation method of a temperature-resistant and salt-resistant multi-polymerization thickener, the steps are as follows:

[0039] S1. Weigh the raw material components according to the following mass percentages: 180 parts of deionized water, 50 parts of acrylamide, 10 parts of 2-acrylamido-2-methylpropyl sodium sulfonate, 4 parts of vinylpyrrolidone, 6 parts of propylene Add morpholine into the reaction kettle, heat to 80°C, stir and mix evenly at constant temperature;

[0040] S2. Introduce nitrogen gas into the reactor for 30 minutes to perform oxygen removal operation, and add 0.08 parts of ammonium persulfate, 0.07 parts of sodium thiosulfate and 0.05 parts of azobisisobutylimidazoline hydrochloride to the mixed material in step S1 Salt, added dropwise for 30 min; after the dropwise addition was completed, stir and react for 10 h;

[0041] S3. After the reaction, the solvent was settled, cooled and solidified, dried naturally, and then sheared and pulverized t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com