Lanthanum oxycarbonate catalyst as well as preparation method and application thereof

A lanthanum oxycarbonate and catalyst technology, applied in the field of catalysts, can solve the problems of reduced C2+ hydrocarbon selectivity, affecting the yield of the target product, affecting the life of the catalyst, etc., and achieves the effects of high selectivity, stable structure and performance, and good catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] In a second aspect, the present invention provides a method for preparing a lanthanum oxycarbonate catalyst, the method comprising: under alkaline conditions, carrying out a hydrothermal reaction with a mixture of a compound containing lanthanum, an optional alcohol and water, and then dissolving the water The solid material after thermal reaction is dried and calcined in sequence to obtain the lanthanum oxycarbonate catalyst.

[0026] According to the present invention, the pH value of the alkaline condition can be selected within a wide range, preferably, the pH value of the alkaline condition is 9-12, for example, it can be 9, 9.5, 10, 10.5, 11 , 11.5, 12, more preferably 9.5-11.5.

[0027] Wherein, the alkaline conditions can be obtained through conventional methods, for example, providing alkaline substances, such as lye, into the system. The alkaline substance can be sodium hydroxide, sodium carbonate, etc., preferably sodium hydroxide. According to a preferred ...

Embodiment approach

[0032] According to a preferred embodiment of the present invention, the preparation method of the mixed solution comprises: under the condition of stirring, dissolving the lanthanum compound in the aqueous alcohol solution, and then adding an alkaline substance therein to provide the alkaline condition , and continue to stir until solids are precipitated, thereby obtaining the mixed solution.

[0033] According to the present invention, in order to further improve the structural uniformity of the lanthanum oxycarbonate, preferably, before performing the hydrothermal synthesis reaction, ultrasonic treatment of the mixed solution is also included. Wherein, the conditions of the ultrasound can be selected within a wide range, preferably, the conditions of the ultrasound include: the frequency is 35-120kHz, for example, it can be 35kHz, 40kHz, 45kHz, 50kHz, 55kHz, 60kHz, 65kHz, 70kHz, 75kHz, 80kHz, 85kHz, 90kHz, 95kHz, 100kHz, 110kHz, 120kHz, preferably 45-100kHz; time is 20-100m...

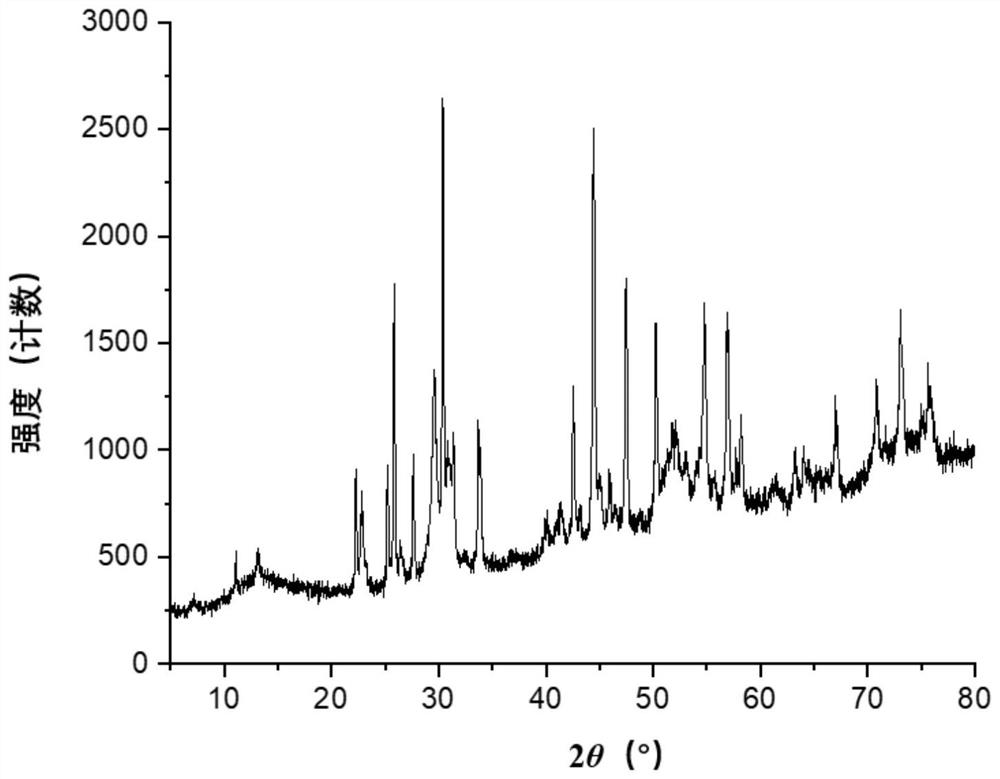

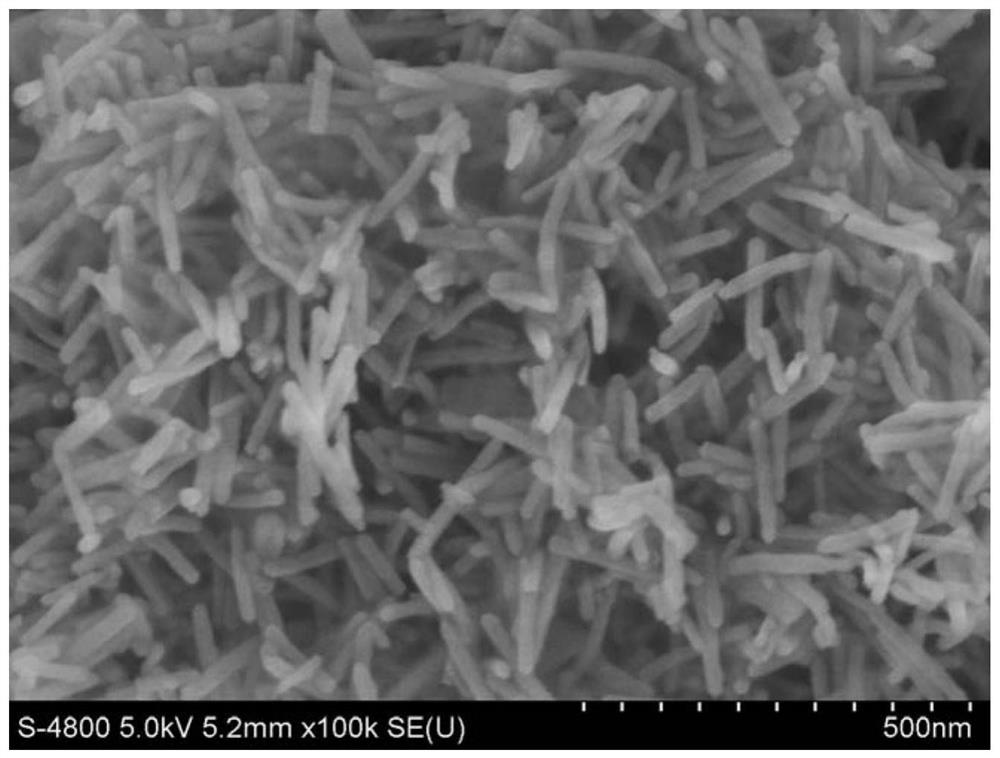

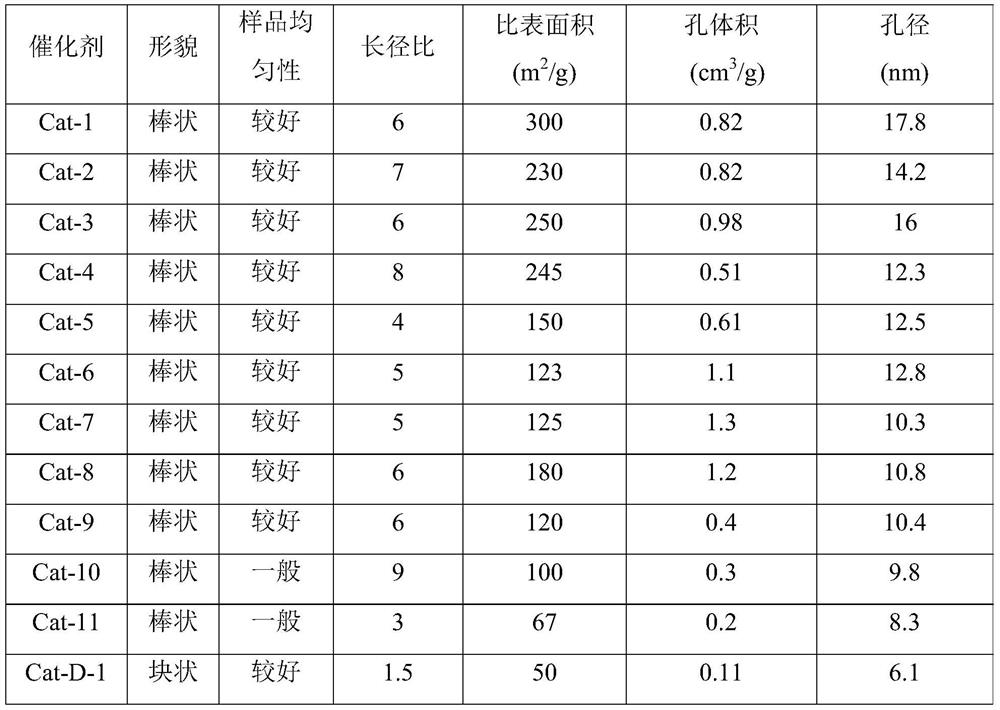

Embodiment 1

[0070] This example is used to illustrate methane oxidative coupling catalyst and its preparation method

[0071] Dissolve lanthanum nitrate hexahydrate in 150g of deionized water and ethanol mixed solution (the weight ratio of water and ethanol is 1:0.1, the amount of lanthanum nitrate hexahydrate makes the amount of lanthanum element 1g), after stirring and dissolving, add 10wt% The sodium hydroxide solution adjusted the pH value of the solution to 10.5, continued to stir until solids were precipitated, transferred the mixed solution to an ultrasonic machine for processing, the frequency was 45kHz, ultrasonic 30min, then adjusted the ultrasonic frequency to 80kHz, ultrasonic 10min, and then adjusted the ultrasonic The frequency is 100KHz, ultrasonic 10min. After sonication, transfer to a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, keep at 160°C for 12h, then centrifuge at 7800rpm for 40min, wash three times with water and once with ethanol, and ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com