Gypsum plaster board

A paper-faced gypsum board and gypsum technology, which is applied in the field of gypsum building materials, can solve the problems of affecting the bonding ability of the protective paper, dampness, and inability to produce insoluble salt, so as to ensure the mechanical strength and moisture-proof performance and reduce the impact of strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

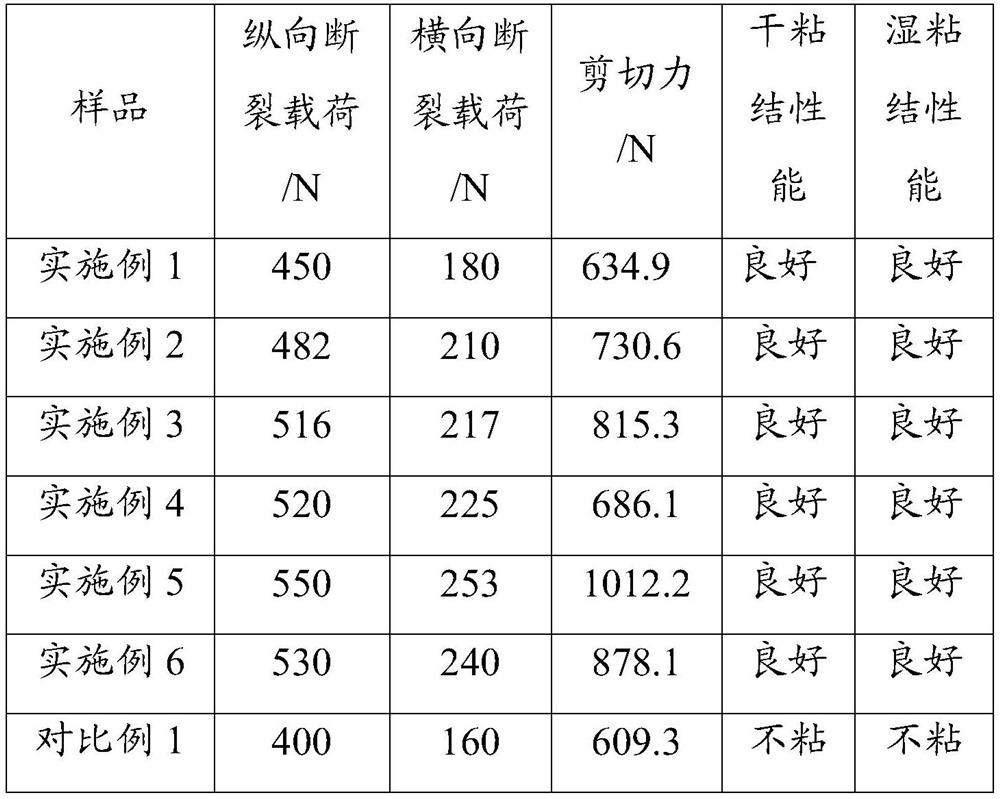

Examples

Embodiment 1

[0024] In this example, the PVA powder was purchased from Taiwan Changchun Group, brand BP-24, with an average degree of polymerization of 2400 and a weight average molecular weight of 118000; polycarboxylate water reducer was purchased from BASF, brand 2651F; glass fiber was Medium-alkali glass fiber with a length of 15mm and a diameter of 10μm.

[0025] Stir 100kg of hemihydrate phosphogypsum powder containing 0.73% chloride ion (grade 85%), 60kg of water, 1.0kg of PVA powder, 10g of glass fiber and 0.5kg of polycarboxylate superplasticizer in a mixer, and then inject it through a metering pump 3kg of sodium lauryl sulfate foaming agent was stirred evenly to make a slurry; the above slurry was combined with upper and lower protective papers to form, cut, and finally dried to obtain a 9.5mm thick gypsum board.

Embodiment 2

[0027] In this example, the PVA powder was purchased from Taiwan Changchun Group, brand BP-24, with an average degree of polymerization of 2400, and a weight average molecular weight of 120,000; polycarboxylate water reducer was purchased from BASF, brand 2651F; glass fiber was E-glass fiber, length 9mm, diameter 15μm.

[0028] In this example, the VAE powder was purchased from Wacker Company, the brand name is TDS-5044N.

[0029] 100kg containing 0.65% chloride ion hemihydrate desulfurization gypsum powder (grade is 80%), 70kg water, 1.0kgPVA powder, 0.1kgVAE powder, 20g glass fiber and 0.5kg polycarboxylate water reducer are stirred in the mixer, and then Inject 5 kg of sodium lauryl sulfate foaming agent through a metering pump, stir evenly to make a slurry; combine the above slurry with upper and lower face protection paper, cut, and finally dry to obtain a 9.5mm thick plasterboard .

Embodiment 3

[0031] In this example, the PVA powder was purchased from Taiwan Changchun Group, brand BP-24, with an average degree of polymerization of 2500 and a weight average molecular weight of 124000; polycarboxylate water reducer was purchased from BASF, brand 2651F; glass fiber was Alkali-resistant glass fiber with a length of 15mm and a diameter of 10μm.

[0032] In this example, the VAE powder was purchased from Wacker Company, the brand name is TDS-5044N.

[0033] 100kg containing 0.60% chloride ion hemihydrate titanium gypsum powder (grade is 85%), 65kg water, 1.0kgPVA powder, 0.2kgVAE powder, 30g glass fiber and 0.5kg polycarboxylate water reducer are stirred in mixer, and then Inject 3kg of sodium lauryl sulfate foaming agent through a metering pump, stir evenly to make a slurry; combine the above slurry with upper and lower face protection paper, cut, and finally dry to obtain a 9.5mm thick plasterboard .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com